Thick hopper control system and method for synthesizing ternary precursor by utilizing same

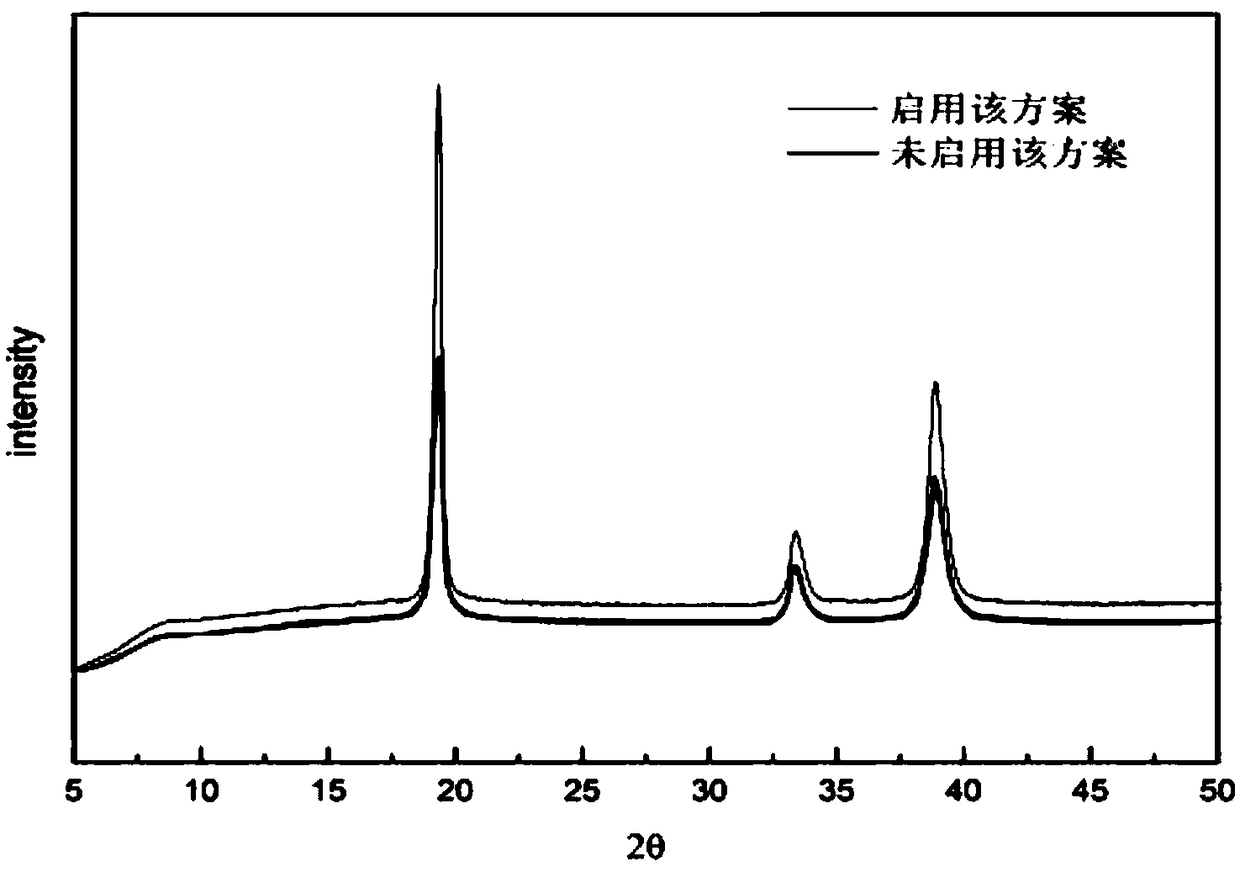

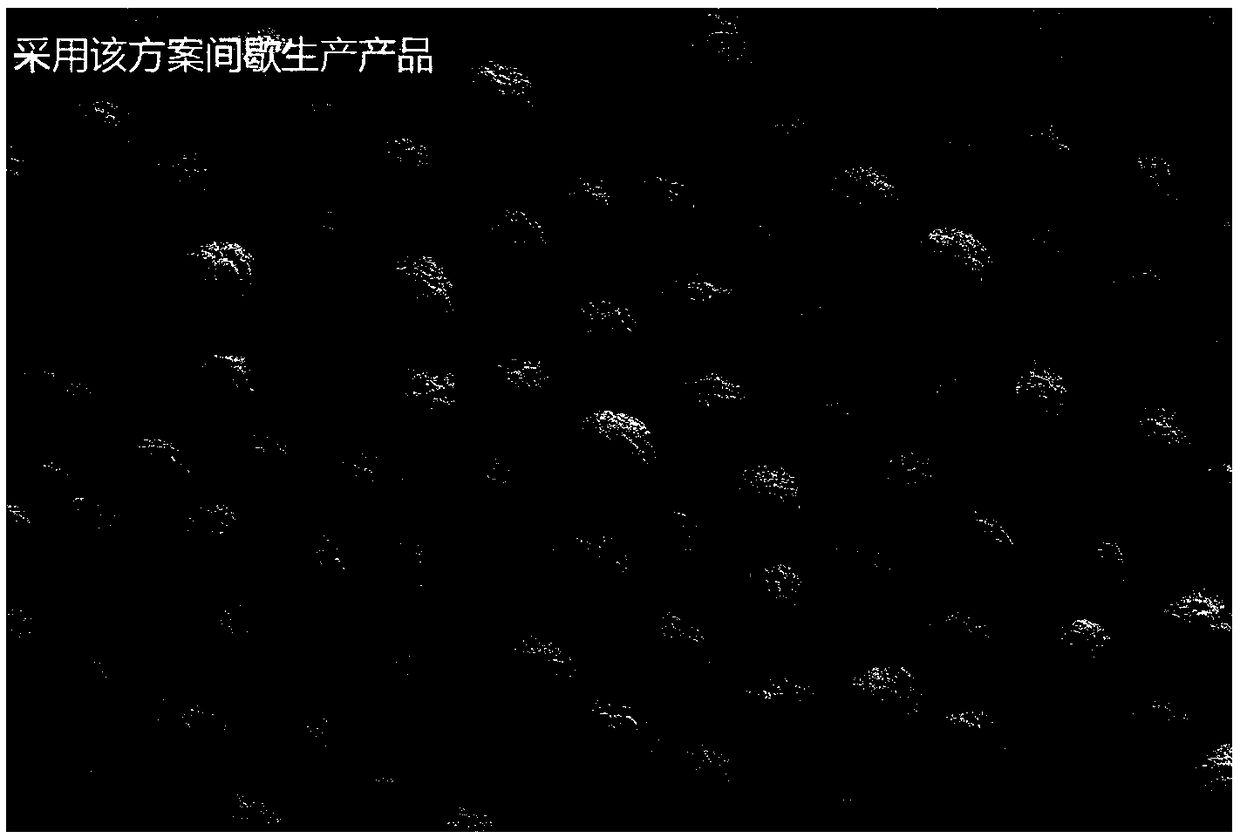

A technology for control systems and precursors, applied in chemical instruments and methods, control/regulation processes, chemical/physical/physical-chemical stationary reactors, etc., can solve the hidden dangers of high-pressure environment safety, high cost of concentrators, and high maintenance costs and other problems, to achieve the effects of excellent physical and chemical indicators, improved crystallinity, and increased number of seeds

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

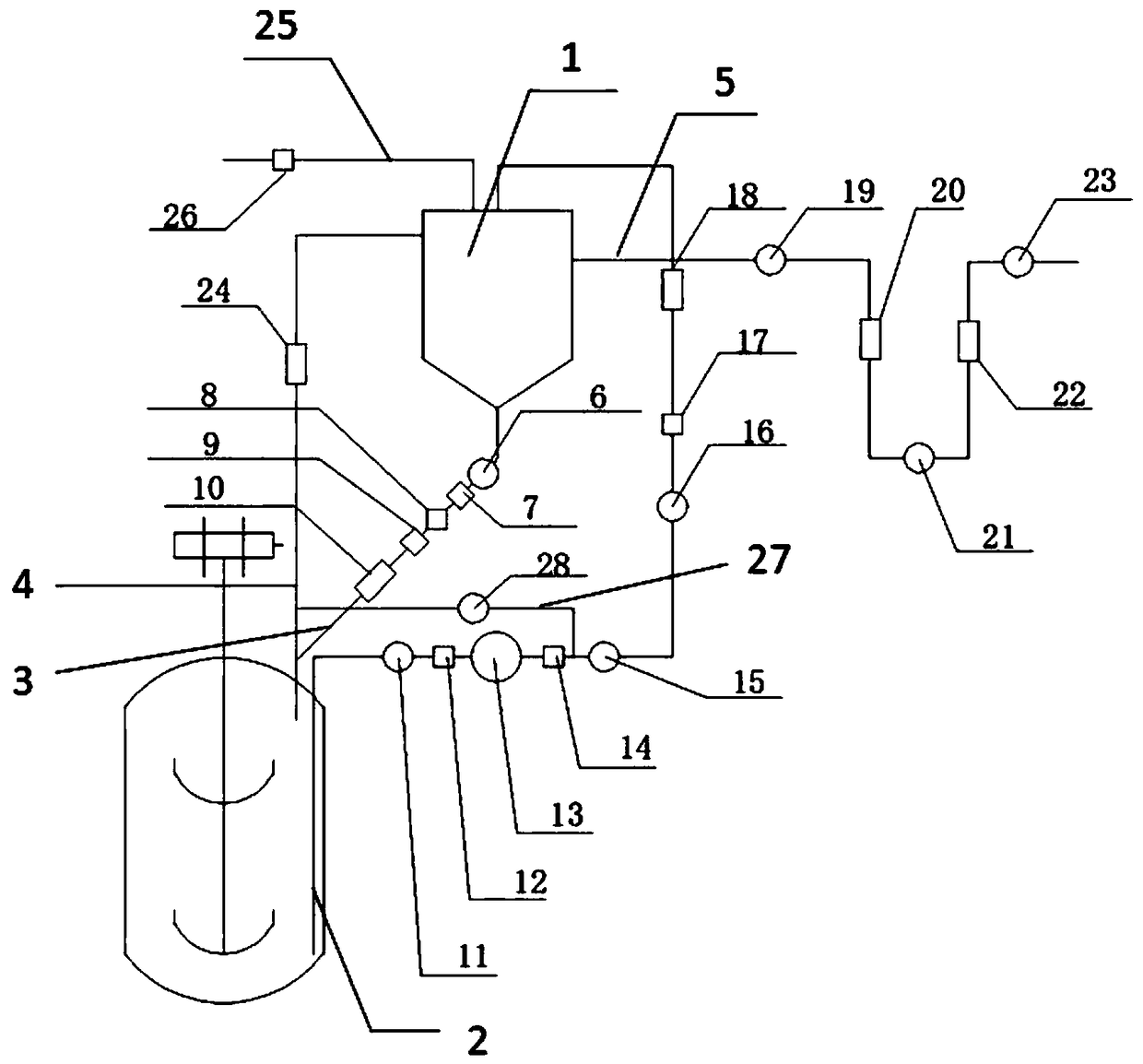

[0028] Such as figure 1 A thickening hopper control system shown includes a thickening hopper 1, a feed pipeline 2, a thick slurry return pipeline 3, a slurry return pipeline 4, and a clearing pipeline 5; one end of the feed pipeline is arranged at the bottom of the reactor, The other end leads to the upper part of the thickening hopper; one end of the slurry return pipeline is set on the upper part of the thickening hopper, and the other end leads to the upper part of the reactor; one end of the thick slurry return pipeline is set at the bottom of the thickening hopper, and the other end leads to the upper part of the reactor and is connected with the slurry The lower end of the material return pipeline is connected; one end of the clearing pipeline is set on the upper part of the thickening bucket; on the thickening slurry return pipeline, a diaphragm valve 6, an expansion joint 7, a vibrator 8, and an expansion joint 2 are arranged in sequence from the place close to the thi...

Embodiment 2

[0030]A method for synthesizing a ternary precursor using a thick bucket control system, comprising the following steps:

[0031] (1) On-site installation of the dense bucket control system as described in embodiment 1, including various pipelines and fittings;

[0032] (2) configuration metal ion concentration is the nickel cobalt manganese salt solution of 2.0mol / L, configuration sodium hydroxide solution concentration 200g / L, configuration ammonia concentration 9.5%; Add sodium hydroxide solution, ammonia liquor in reaction kettle bottom liquid, adjust The ammonia concentration is 3.5-5.5g / L, and the pH value is 10.0-12.0; the nickel-cobalt-manganese salt solution, sodium hydroxide solution, and ammonia water are added to the reactor at the same time, the reaction temperature is 50-70°C, the speed is controlled at 100-300rpm, and Maintain the pH value of 10.0-12.0, ammonia concentration 3.5-5.5g / L; and continuously feed nitrogen or argon gas to protect the slurry in the rea...

Embodiment 3

[0039] A method for synthesizing a ternary precursor using a thick bucket control system, comprising the following steps:

[0040] (1) On-site installation of the dense bucket control system as described in embodiment 1, including various pipelines and fittings;

[0041] (2) configuration metal ion concentration is the nickel cobalt manganese salt solution of 2.0mol / L, configuration sodium hydroxide solution concentration 200g / L, configuration ammonia concentration 9.5%; Add sodium hydroxide solution, ammonia liquor in reaction kettle bottom liquid, adjust The ammonia concentration is 8.5-9.5g / L, and the pH value is 10.0-12.0; the nickel-cobalt-manganese salt solution, sodium hydroxide solution, and ammonia water are added to the reactor at the same time, the reaction temperature is 50-70°C, the speed is controlled at 100-300rpm, and Maintain the pH value of 10.0-12.0, ammonia concentration of 8.5-9.5g / L; and continuously feed nitrogen or argon and other gases to protect the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com