Protective gas nanobubble generation device

A protective gas and nano-bubble technology, applied in the direction of inert gas generation, gas/steam and liquid mixing, transportation and packaging, etc., can solve the problems of low precision, complex structure, difficult to form nano-bubbles, etc., to achieve working condition adaptation Strong capability, simple equipment structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

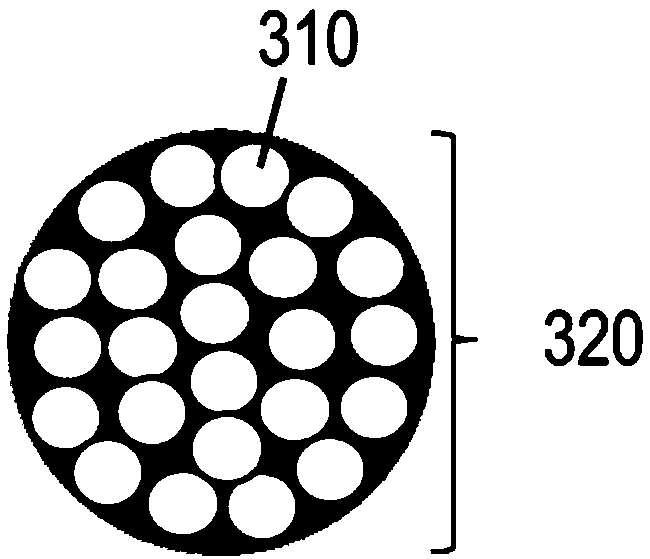

[0082] use Figure 6 When the equipment shown is working, first set the monitoring value range of the pressure sensor to 14.9-15.1Mpa through the chain control system, open the intake control valve, and high-pressure nitrogen enters the pressure vessel through the gas delivery pipeline. When the pressure in the pressure vessel exceeds 15.1 At Mpa, the intake control valve is closed, and at this time, water with a dissolved nitrogen content of 1 ppm is introduced into a pressure vessel filled with 15.1 MPa nitrogen through an atomizing nozzle (stainless steel, 6 mm inner diameter). The water sprayed from the atomizing nozzle is in the form of mist, and the water droplets dissolved in nitrogen are collected at the bottom of the pressure vessel. The collected water exits the pressure vessel through a conduit and is sprayed at the end of the output line through a bundle of borosilicate capillary tubes (inner diameter 5mm) into the tank. The dissolved nitrogen content measured at ...

Embodiment 2

[0085] use Figure 6 When the equipment shown is working, first set the monitoring value range of the pressure sensor to 9.9 ~ 10.0Mpa through the chain control system, and then open the atomizing nozzle and the air intake control valve at the same time to make the aqueous solution containing 5% glucose (D 5 W solution) and nitrogen enter the pressure vessel at the same time, the pressure of the pressure vessel rises gradually, and the D dissolved in nitrogen 5 The W solution was sprayed into the water tank through a bundle of borosilicate capillary tubes (inner diameter 0.5 mm). Under an argon ion laser emitting light at 488 / 515nm wavelength, observe the nitrogen-dissolved D as it exits the capillary nozzle 5 In solution W, no bubbles with a diameter greater than 500 nm were observed. After working for a period of time, the internal pressure of the pressure vessel rises above 10Mpa, the pressure sensor feeds back to the PLC control system, and the intake control valve autom...

Embodiment 3

[0088] use Figure 6When the equipment shown is working, first set the monitoring value range of the pressure sensor to 4.9-5.1Mpa through the chain control system, open the intake control valve, and high-pressure nitrogen enters the pressure vessel through the gas delivery pipeline. When the pressure in the pressure vessel exceeds 5.1 At Mpa, the intake control valve is closed, and water is introduced into a pressure vessel filled with 5.1 MPa nitrogen through an atomizing nozzle (stainless steel, 6 mm inner diameter). The water sprayed from the atomizing nozzle is in the form of mist, and the water droplets dissolved in nitrogen are collected at the bottom of the pressure vessel. The collected water exits the pressure vessel through a conduit and is sprayed into the albumin solution at the end of the outlet line through a bundle of borosilicate capillaries (1 mm inner diameter). Use a submicron particle size analyzer (Tri-Blue Microtrac, Leeds & Northrup Instruments) to che...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com