VOCs absorption method

An absorption tower and absorbent technology, which is applied in the field of treatment and recovery of VOCs unorganized emissions in sewage treatment plants, can solve the problems of high price, unfavorable gas absorption, and VOCs not reaching the ideal effect, so as to achieve high utilization rate and ensure absorption effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] The components and mass fractions of a water-in-ionic liquid (IL / W) type VOCs absorbent are:

[0057]

[0058] Prepare the above-mentioned VOCs absorbent to absorb the original exhaust gas. The specific steps are:

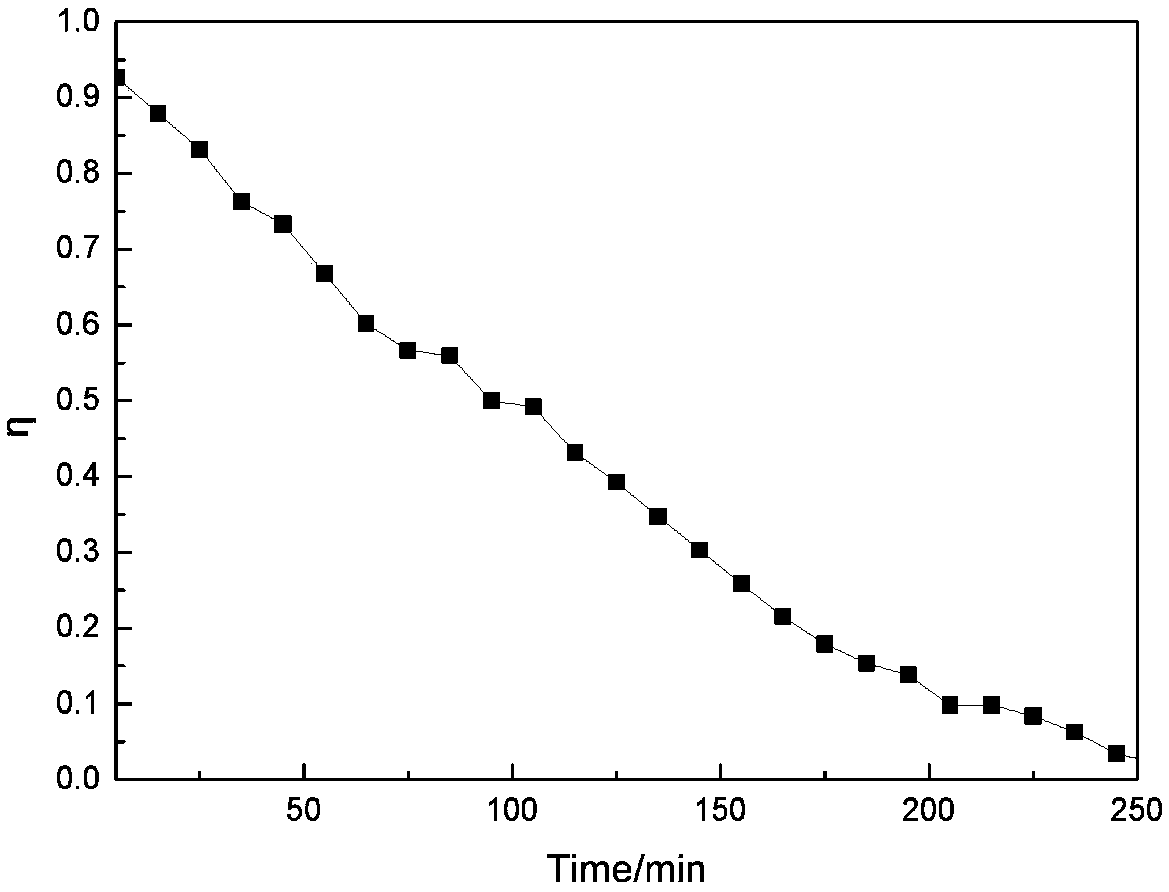

[0059] In 5g[DDMIM][NTf 2 ], add 8g of Tween-80, then add 5g of n-butanol, shake well, mix 82g of water with 3ml·min under stirring -1 The speed is added in the above-mentioned solution, obtain microemulsion, prepare three parts of microemulsions standby according to above-mentioned steps (prepare three parts of microemulsions, every part is 100g, three absorption towers have been used in this example, so each absorption tower absorbent For 100g, the data analysis is the absorption effect of 200g, because the actual absorption is two towers participating in the absorption).

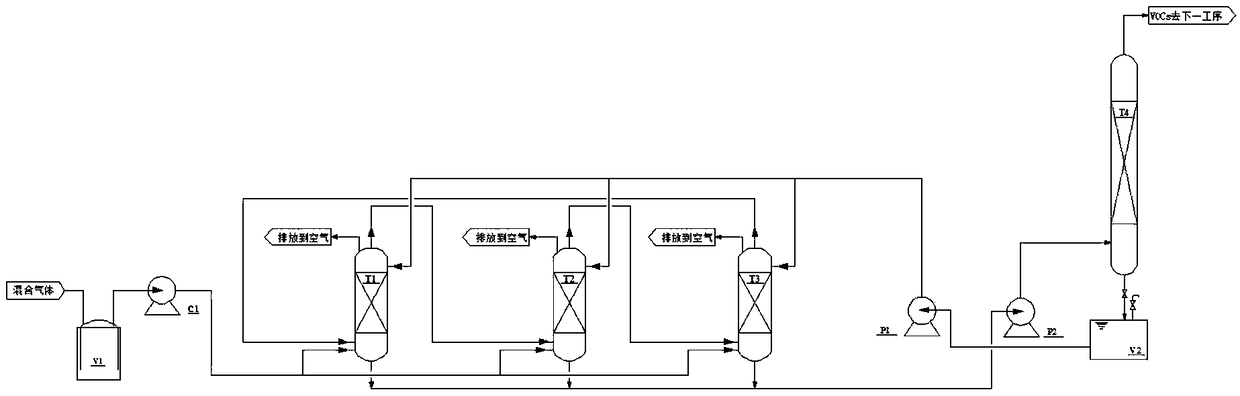

[0060]The present invention adopts multi-absorption operation to install 3 absorption devices, the actual working process is 2 absorption devices, and the remaining absorption devi...

Embodiment 2

[0063] The components and mass fractions of a water-in-ionic liquid (IL / W) type VOCs absorbent are:

[0064]

[0065] Prepare the above-mentioned VOCs absorbent to absorb the original exhaust gas. The specific steps are:

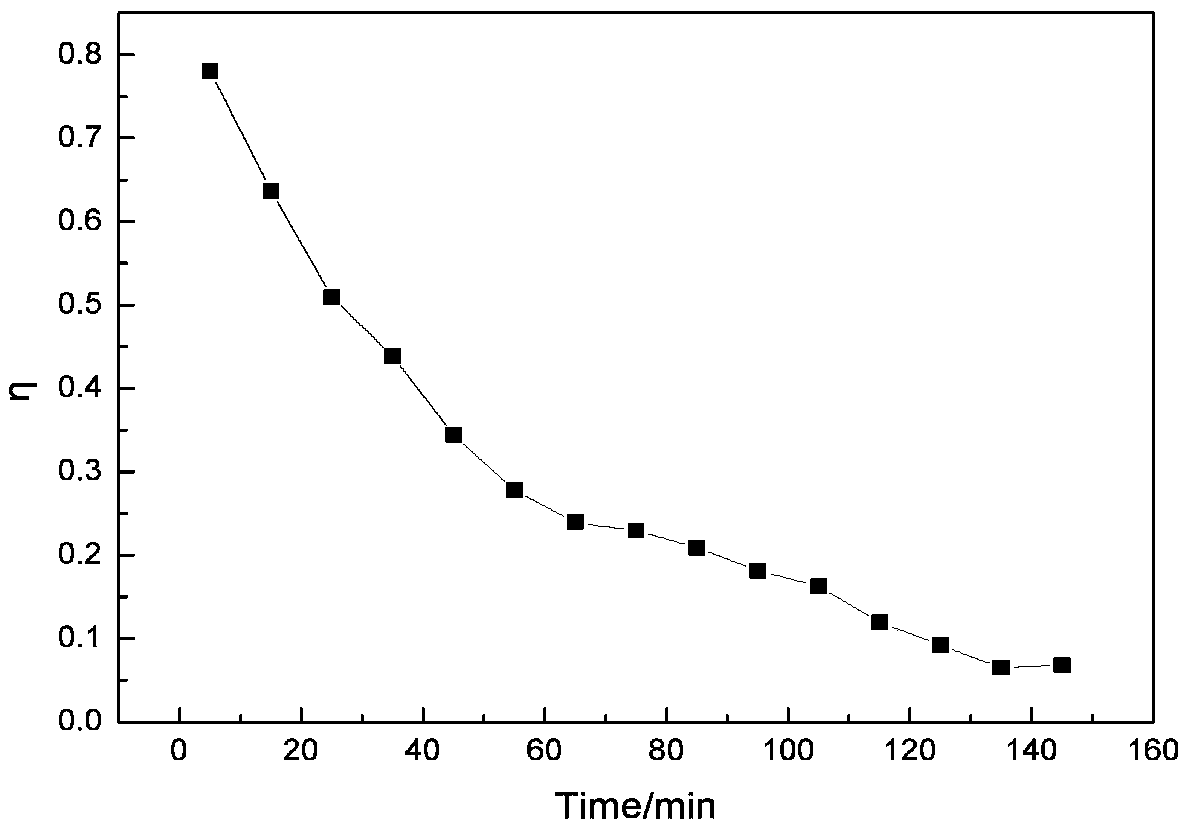

[0066] In 5g[DDMIM][NTf 2 ], add 8g of Tween-80, then add 5g of n-butanol, shake well, mix 82g of water with 3ml·min under stirring -1 The speed is added to the above solution to obtain a microemulsion; the mixed organic waste gas containing aromatics, halogenated hydrocarbons and other VOCs is concentrated into the microemulsion. The air pipe is discharged, and the outlet is the purified gas. The initial absorption rate of the absorbent for VOCs can reach more than 78%; separate. This example uses a single-stage absorption operation. Gas intake concentration 2000mg·m -3 , intake flow 0.1Nm 3 h -1 , the absorbent maintains a constant temperature of 303.15K, and the gas residence time is 4s.

[0067] Such as image 3 As shown, when the absorption ...

Embodiment 3

[0069] The components and mass fractions of a water-in-ionic liquid (IL / W) type VOCs absorbent are:

[0070]

[0071]

[0072] Prepare the above-mentioned VOCs absorbent to absorb the original exhaust gas. The specific steps are:

[0073] In 6g[BMIM][PF 6 ], add 10g of Tween-80, then add 6g of n-butanol, shake well, mix 78g of water with 3ml·min under stirring -1 The speed is added in the above-mentioned solution, obtains microemulsion, prepares three parts of microemulsions standby according to above-mentioned steps.

[0074] The present invention adopts multi-absorption operation to install 3 absorption devices, the actual working process is 2 absorption devices, and the remaining absorption devices carry out the desorption process, such as figure 1 As shown, the mixed gas is concentrated in the mixed gas gas cabinet V1, through the gas compressor C1, the optimal intake concentration and intake speed are adjusted, and it is concentrated into the VOCs absorption tower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com