Efficient and energy-saving reducing furnace chassis and polycrystalline silicon reducing furnace

A high-efficiency, energy-saving, reducing furnace technology, applied in silicon compounds, chemical instruments and methods, sustainable manufacturing/processing, etc., can solve problems such as poor quality, increased production costs, and large disturbances, and achieve consistent growth quality and improved Conversion rate, the effect of uniform gas field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to enable those skilled in the art to better understand the technical solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

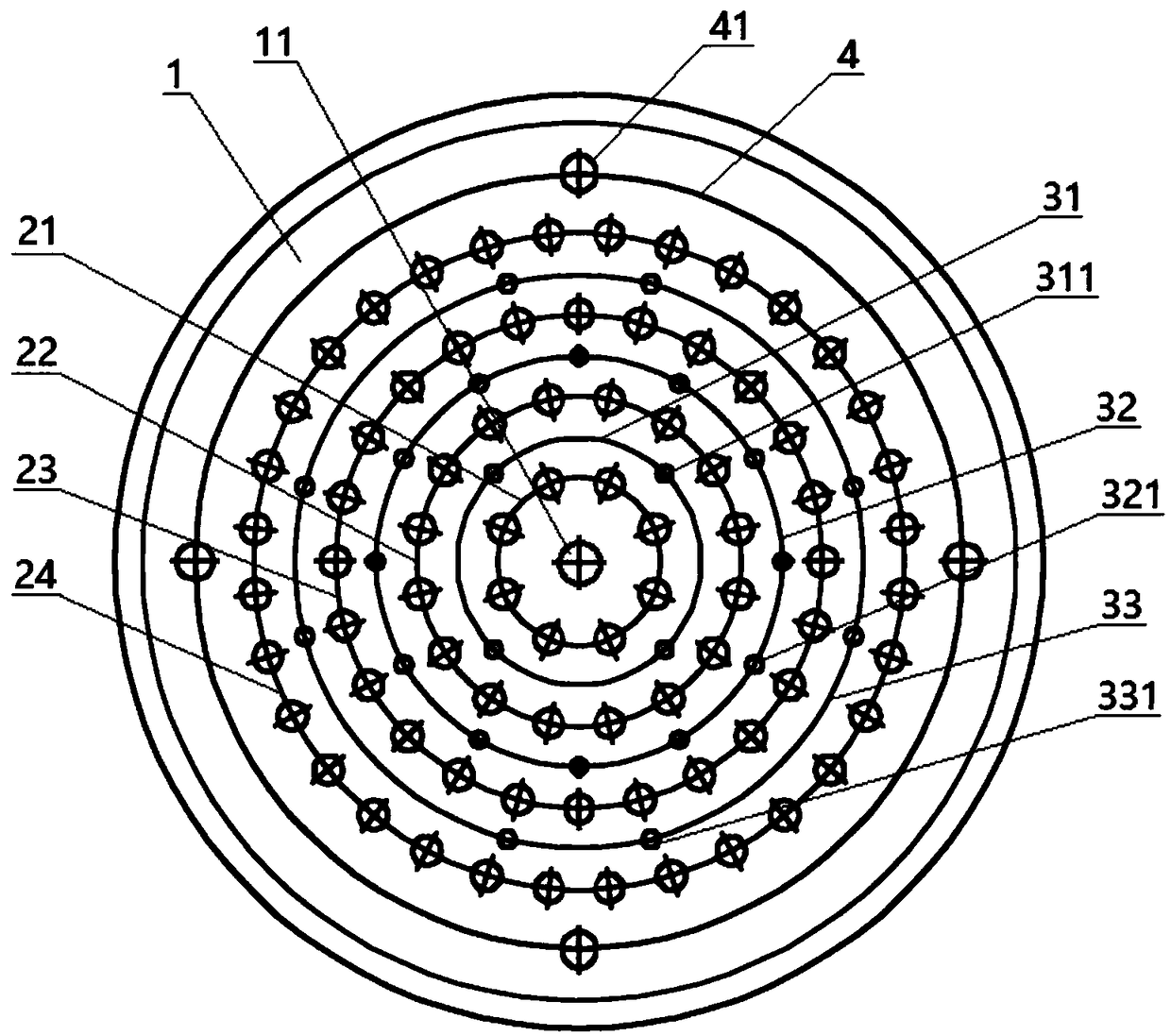

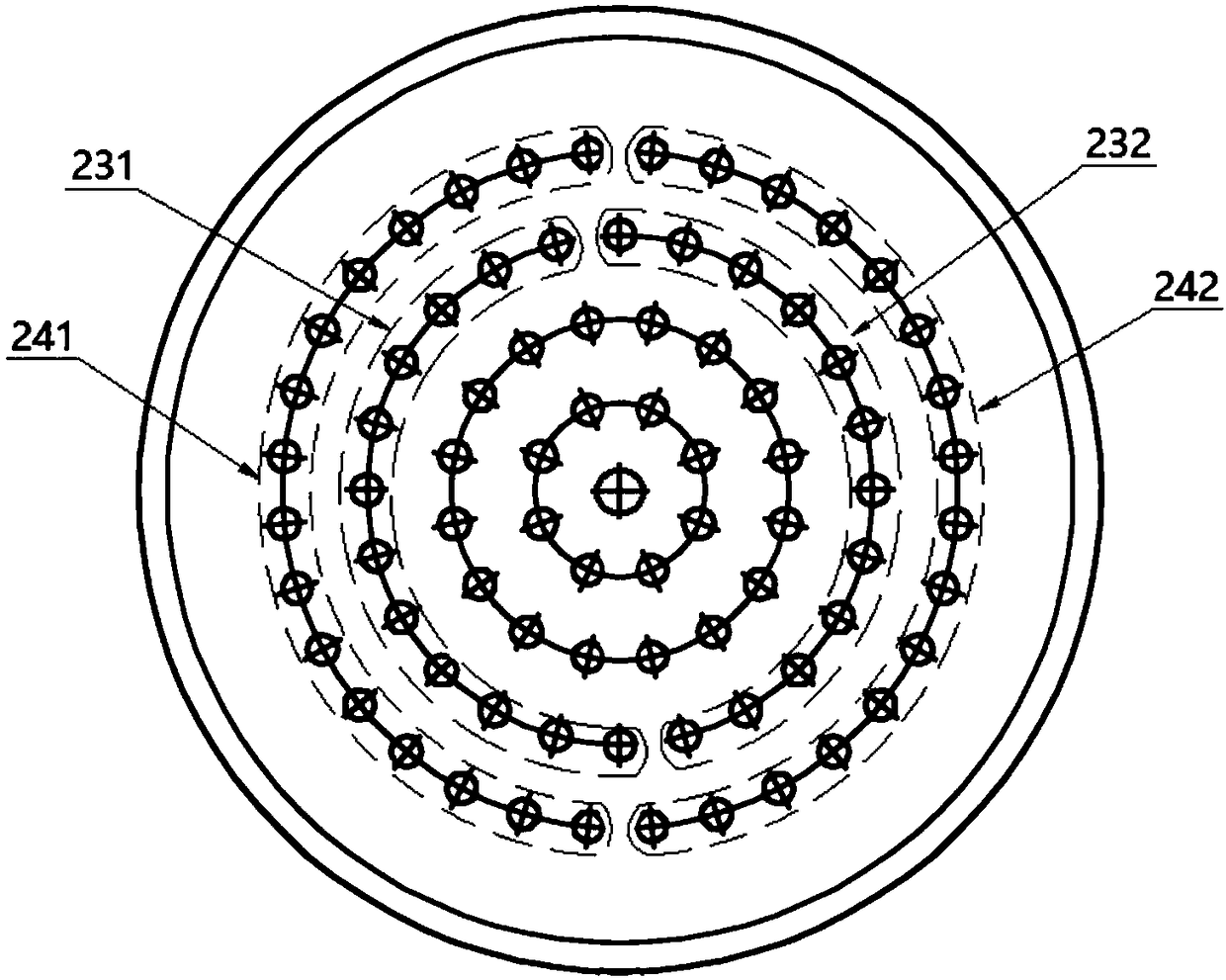

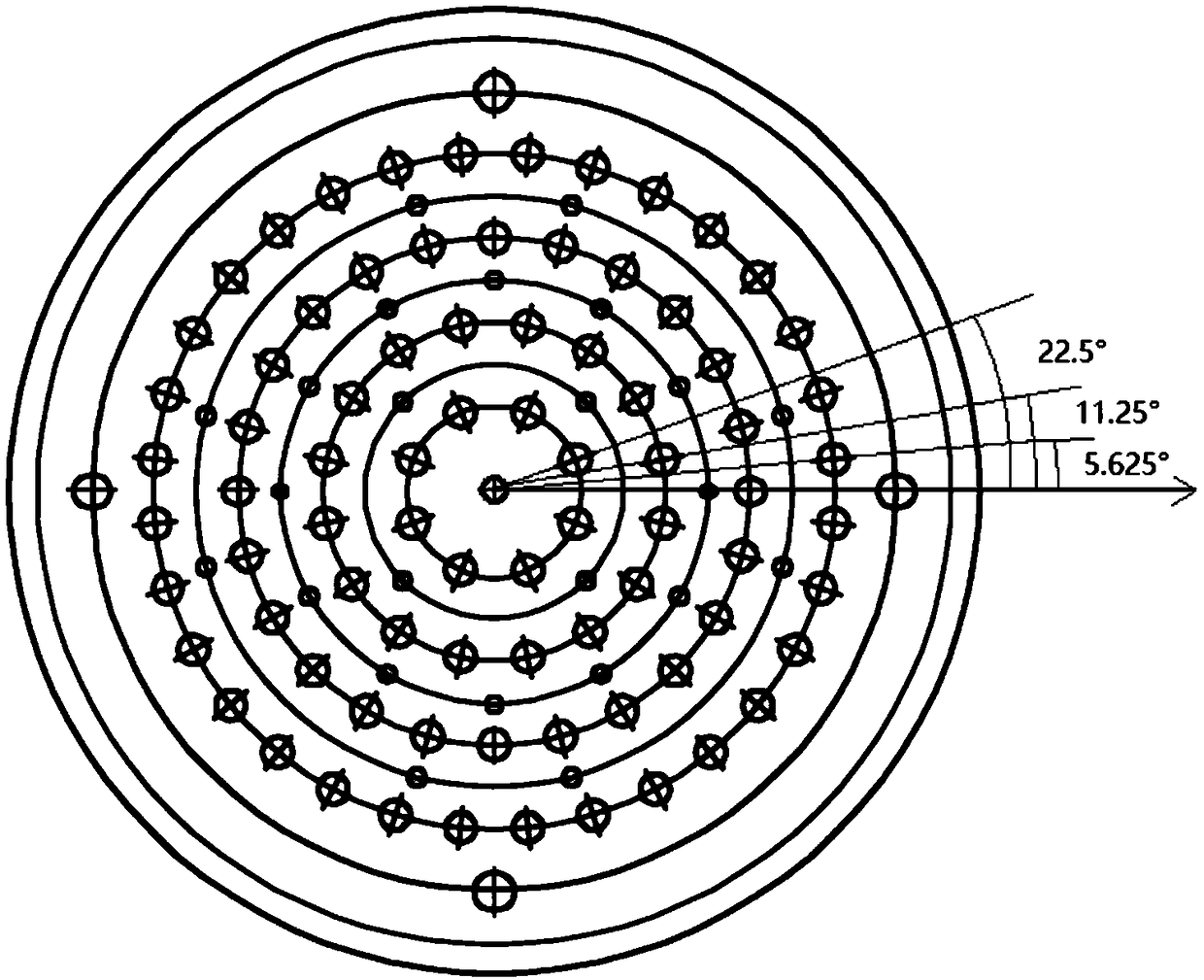

[0039] Please refer to figure 1 , the embodiment of the present invention provides a high-efficiency energy-saving reduction furnace chassis, including a chassis body 1, a central feeding port 11, 4 electrode ring layers and 3 feeding ring layers are arranged on the chassis body 1, and the electrode ring layers and The feeding ring layer is arranged at intervals with the central feeding port 11 as the center of the circle; from the inside to the outside are the first electrode ring layer 21, the first feeding ring layer 31, the second electrode ring layer 22, the second feeding ring layer 32, The third electrode ring layer 23 , the third feed ring layer 33 and the fourth electrode ring layer 24 .

[0040]The first electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com