Polyester reflection film as well as preparation method and application thereof

A reflective film, polyester technology, applied in chemical instruments and methods, photovoltaic power generation, electrical components, etc., can solve the problems of high production stability and low cost, and achieve good stiffness, strong wrinkle resistance, and low density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

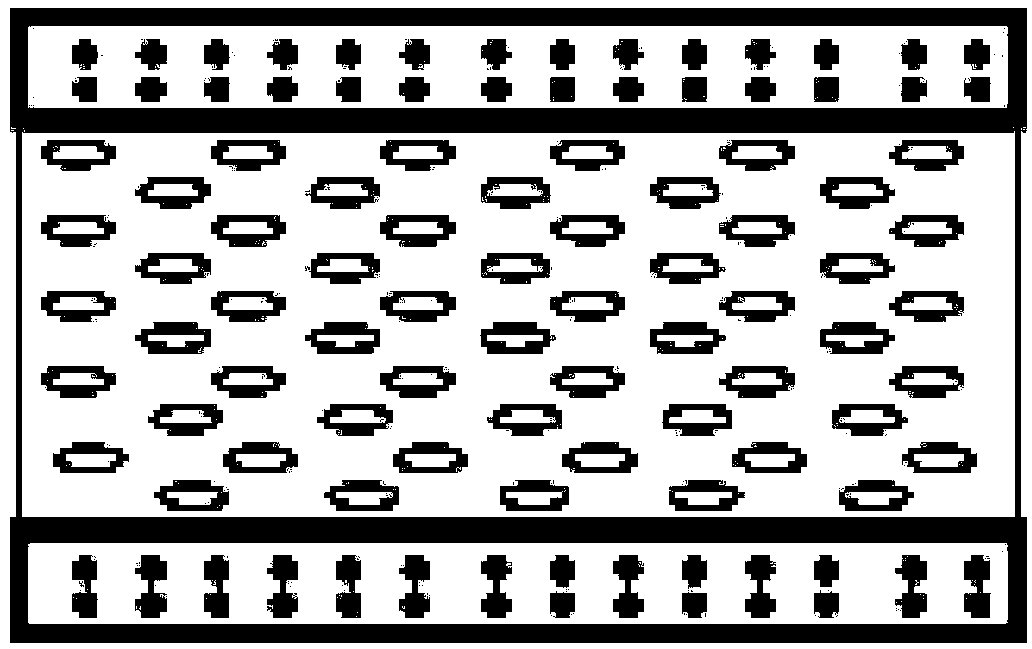

Image

Examples

Embodiment 1

[0032] The preparation method of polyester reflective film of the present invention is made by following method:

[0033] The polyethylene terephthalate (trade name SB500, Yizheng Chemical Fiber System) of 72 parts by mass, 20 parts of rutile titanium dioxide white masterbatch (trade name S598, titanium dioxide content 60%, Shanghai Hongyu supply ) and 8 parts of silicone particle masterbatch (the particle size of the silicone particle in the masterbatch is 1um, the content is 50%), pre-crystallized at 160°C, and then dried at 180°C for 3 hours, then added to temperature In a single-screw extruder B at 270-280°C, a melt layer B is obtained;

[0034] At the same time, the mass parts are 10 parts of rutile titanium dioxide white masterbatch, 20 parts of barium sulfate white masterbatch (trade name MB41, wherein barium sulfate content is 60%, Shanghai Hongyu supplies), 1 part of organic silicon particle masterbatch material (silicone particle size is 5um, content 50%), 2 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com