Efficient double liquid dragging mechanism of continuous full-width cold pile dyeing/bleaching padding

A technology of cold stacking and padding, applied in the field of continuous open-width cold stacking dyeing/bleaching equipment, can solve the problems of color difference cloth roll head and tail hair effect, left, middle and right color difference, color flower left, middle and right hair effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

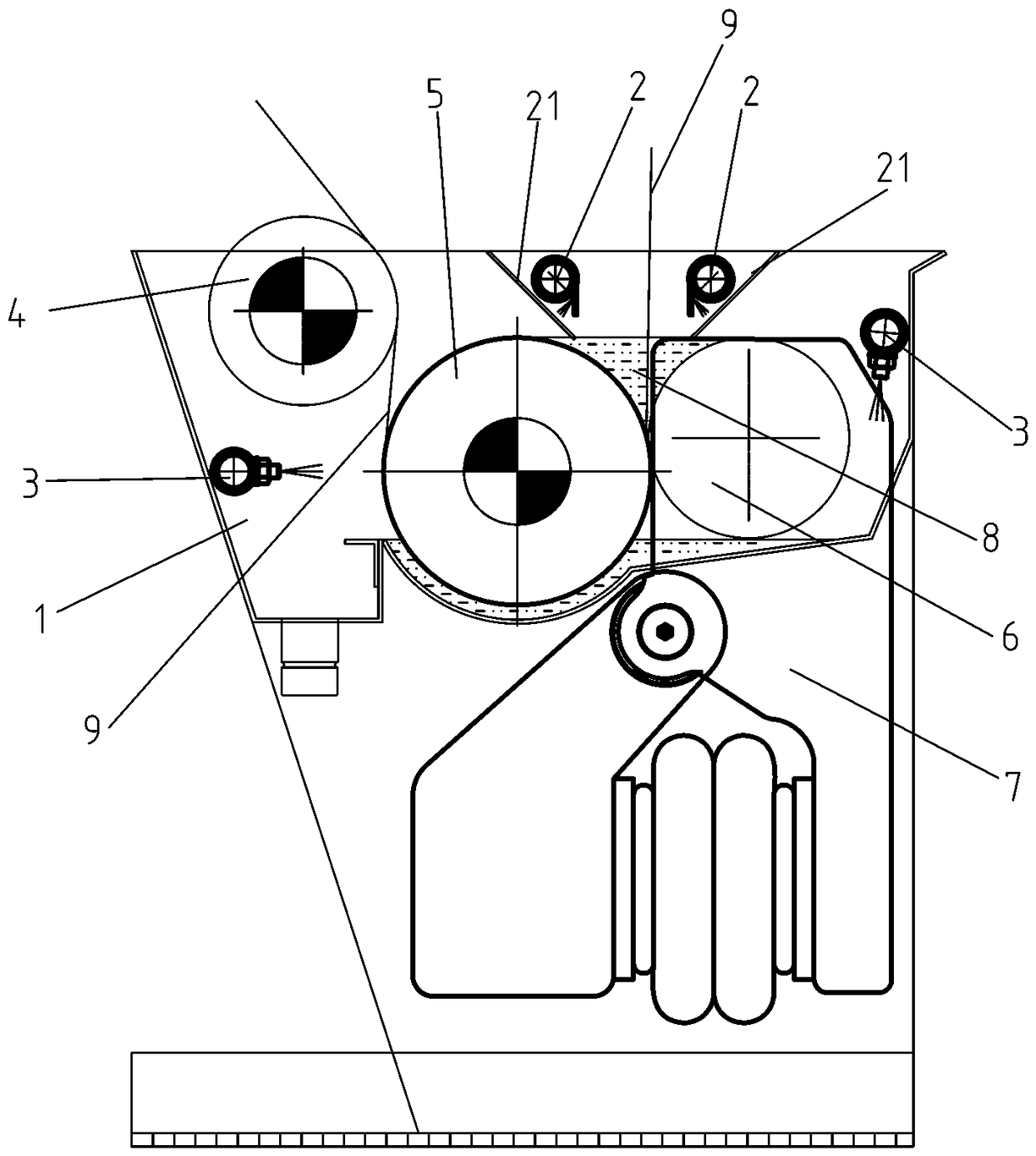

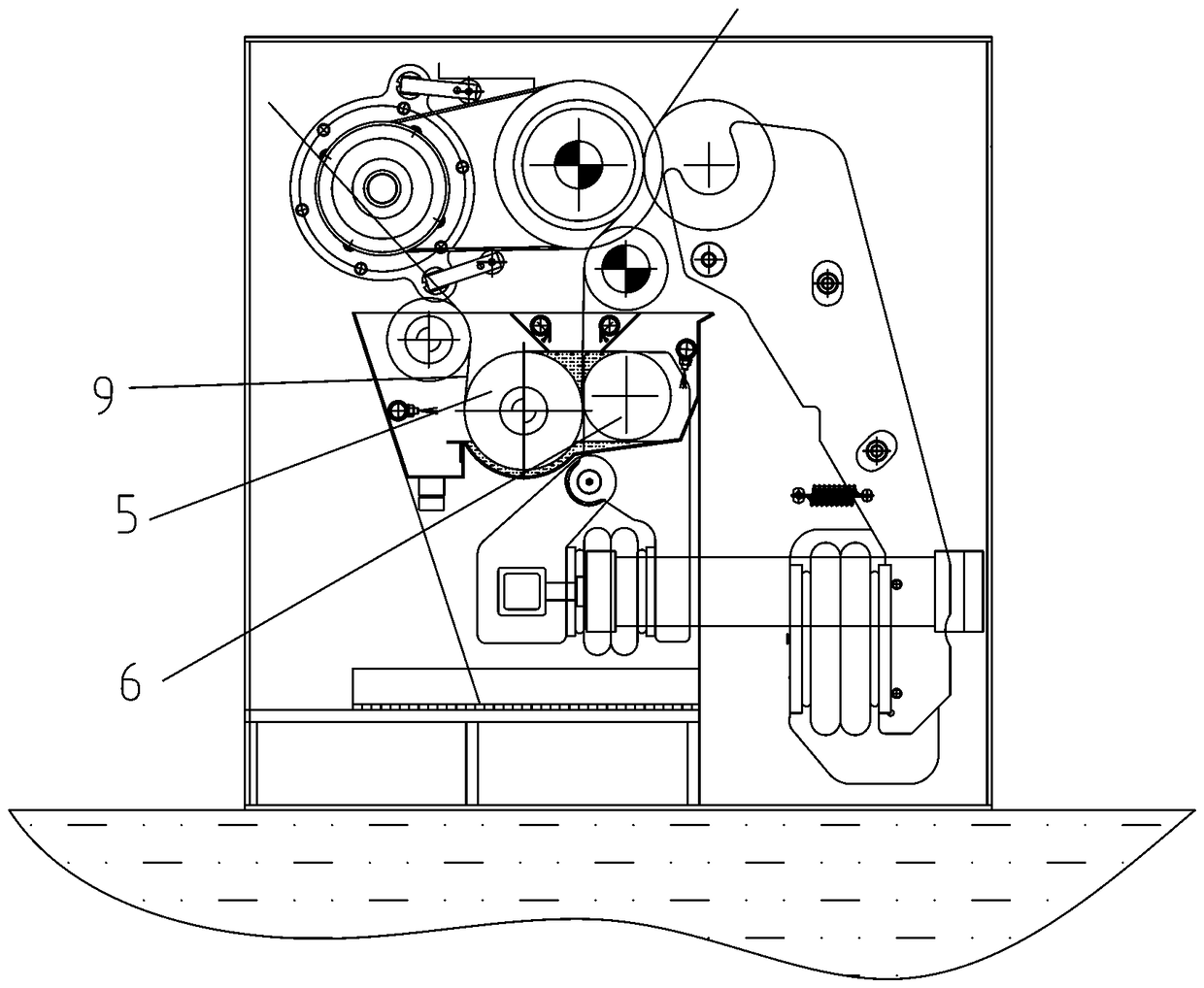

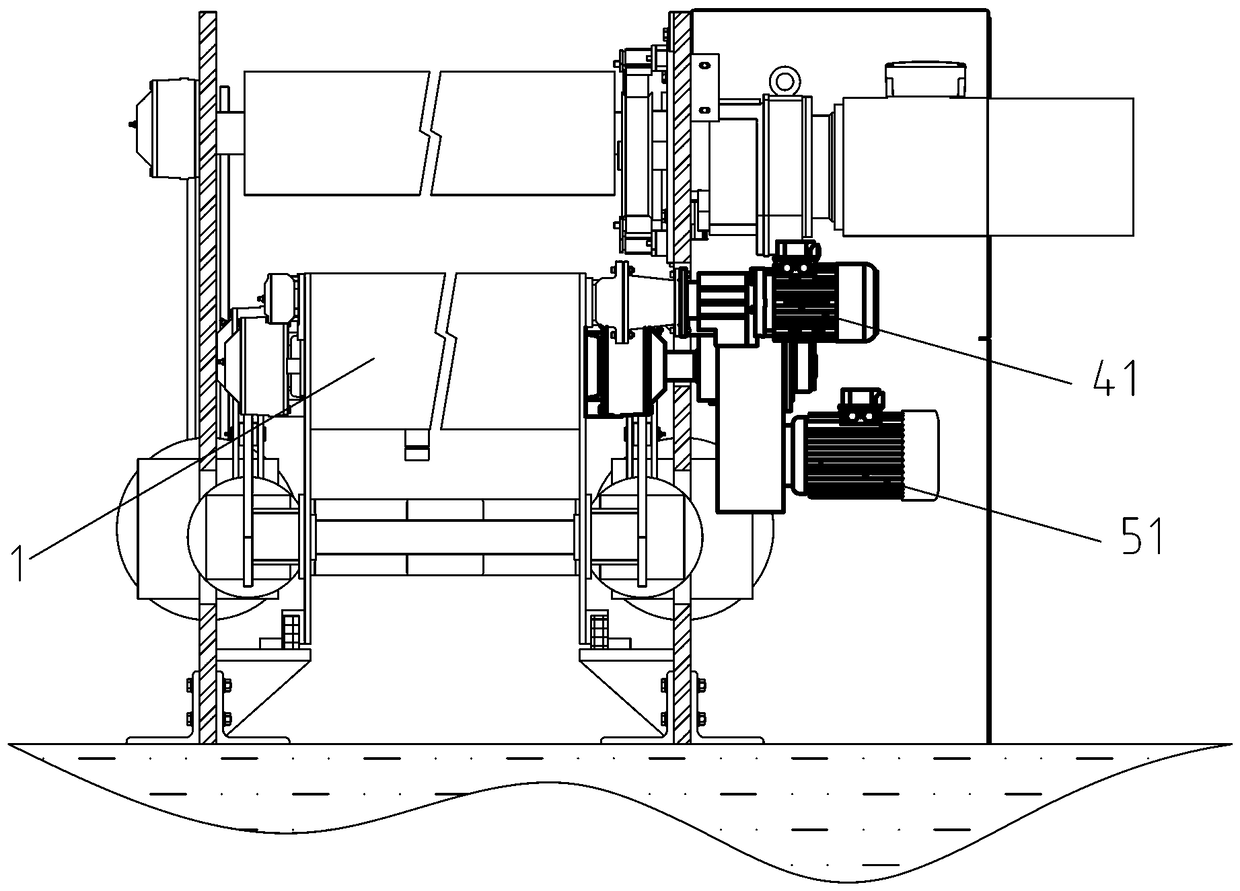

[0022] The structure of the present invention will be further described below in conjunction with the accompanying drawings and preferred specific embodiments of the present invention.

[0023] refer to Figure 1 to Figure 3 As shown in , the high-efficiency double-carrying liquid mechanism of the continuous open-width cold-batch dyeing / bleaching pad of the present invention includes a working liquid immersion tank 1, and a driving roll higher than the water level line is arranged in the working liquid immersion tank 1 5 and the passive roller 6; the driving roller 5 and the passive roller 6 are arranged side by side to form a pre-rolling liquid roller group, and the pre-rolling liquid roller group is used to uniformly roll the pre-impregnated fabric 9 in the working liquid dipping tank 1 from bottom to top to produce rolling Liquid effect; both sides of the driving roll 5 and the passive roll 6 are provided with water retaining plates made of wear-resistant sealing materials,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com