Pigment with high brightness, color purity and covering effect and preparation method of pigment

A high-brightness, pigment technology, applied in the field of pigments, can solve the problems that excellent effects cannot be fully reflected, affect the display and play of special color effects, and achieve the effect of maintaining mechanical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

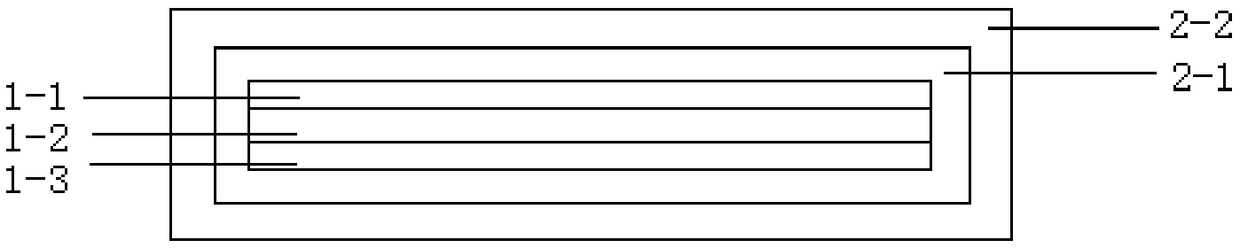

[0076] The core material of the pigment in this embodiment is a single layer of silicon dioxide, and the outer coating layer is titanium dioxide.

[0077] Use vacuum sputtering technology to deposit a layer of zinc sulfide of about 10nm on the substrate glass plate, followed by deposition of silicon dioxide until it reaches 170nm, then deposit about 10nm of zinc sulfide, and then continue to deposit silicon dioxide 170nm, repeat Repeat the above process for 10 cycles, and the total thickness reaches about 2um. Afterwards, the material was immersed in hydrochloric acid (concentration: 35%) for about 30 minutes to remove zinc sulfide and obtain a silicon dioxide sheet with a very high surface smoothness and a thickness of 170 nm. After subsequent washing and classification, the particle size distribution was 20. - 100um core material precursor, used as a substrate for subsequent cladding, with a thickness of 170±2nm.

[0078] Then 40 g of the core material precursor was dispersed...

Embodiment 2

[0081] The core material of the pigment in this embodiment is a single layer of silicon dioxide, and the outer coating layer is a mixed coating layer of titanium dioxide and ferric oxide.

[0082] Use vacuum sputtering technology to deposit an organic peelable isolation layer of about 10nm on the base glass plate first, then deposit silicon dioxide until it reaches 80nm, then deposit an organic peelable isolation layer of about 10nm, and then continue to deposit two layers. Silicon oxide 80nm, repeat the above process repeatedly, repeat 20 cycles, the total thickness reaches about 2um. Then immerse the material in a release agent, remove the peelable isolation layer, and obtain a silicon dioxide sheet with a very high surface smoothness and a thickness of 80nm. After subsequent washing and classification, a core material with a particle size distribution of 10-60um is obtained. The precursor is used as the substrate for subsequent wet chemical coating, and its thickness is 80±...

Embodiment 3

[0086] The core material of the pigment in this embodiment is a single layer of aluminum oxide, and the outer cladding layer is iron oxide.

[0087] Use vacuum sputtering technology to deposit an organic strippable isolation layer of about 10nm on the substrate glass plate, then deposit aluminum oxide until it reaches 100nm, then deposit a strippable isolation layer of about 10nm, and then continue to deposit Al2O3 100nm, repeat the above process repeatedly, repeat 20 cycles, the total thickness reaches about 2um. Then immerse the material in an organic release agent to remove the peelable isolation layer to obtain aluminum oxide with a very high surface smoothness and a thickness of 100nm. After subsequent washing and grading treatment, a core with a particle size distribution of 40-80um is obtained. The material precursor is used as the substrate for subsequent wet chemical coating, and its thickness is 100±1.5nm.

[0088] Then disperse 40g of the substrate in 1L of water, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com