Bathroom cabinet wood pre-treatment technology

A pretreatment and bathroom cabinet technology, applied in wood treatment, wood treatment details, wood processing equipment, etc., can solve the problems of reduced service life of bathroom cabinets, mildew and deformation of cabinets, leakage of bathroom cabinets, etc., to speed up the combination , temperature uniformity, the effect of reducing moisture content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

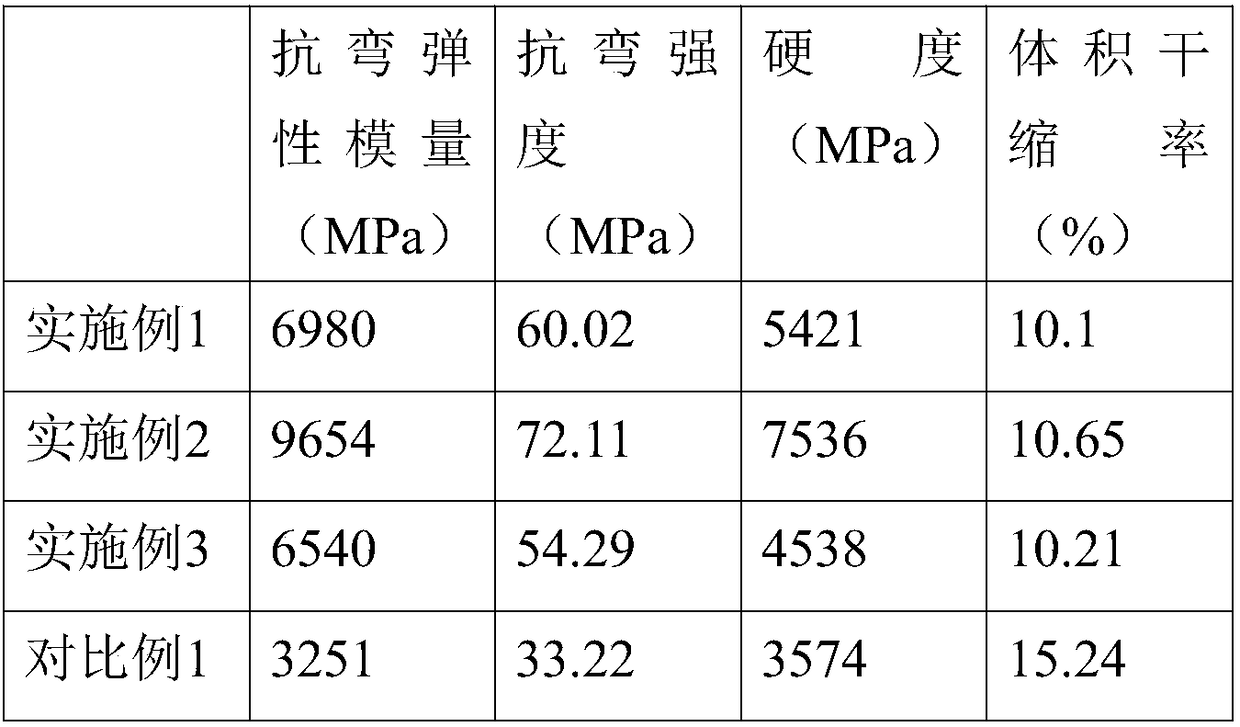

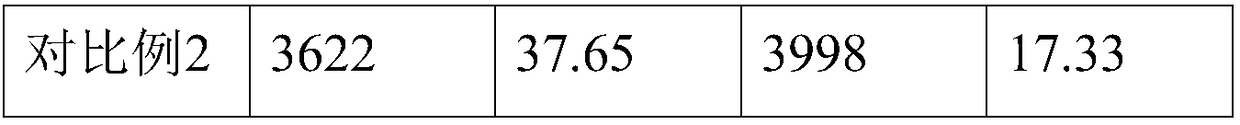

Examples

Embodiment 1

[0031] A bathroom cabinet wood pretreatment process, comprising the following steps:

[0032] S1: Wood pretreatment: first place the wood in a cool and ventilated place to air-dry for 8 days, and then process the wood into boards of various specifications and thicknesses;

[0033] Use an acetylene cutting torch to bake at a high temperature of 1500 degrees and move the flame at a constant speed of 4 cm per second to open the hidden small cracks on the surface of the wood. The high-temperature flame can remove some burrs at the same time and make the wood texture clearer. Grinding and polishing with a sandpaper wheel, subject to the ability to remove the superficial carbonized charred part of the wood;

[0034] S2: Configure coating slurry: the coating slurry is calculated in parts by weight, including: 5kg of natural lacquer, 3kg of vegetable wax, 60kg of vegetable oil, 1kg of rosin glycerin, and 5kg of additives;

[0035] S3: Apply the configured coating slurry on the board ...

Embodiment 2

[0051] A bathroom cabinet wood pretreatment process, comprising the following steps:

[0052] S1: Wood pretreatment: first place the wood in a cool and ventilated place to air-dry for 12 days, and then process the wood into boards of various specifications and thicknesses;

[0053] Use an acetylene cutting torch at a high temperature of 1500 degrees, and burn at a constant speed of 5 cm per second to open the hidden small cracks on the surface of the wood. The high-temperature flame can remove part of the burrs at the same time, making the wood texture clearer. Use after roasting Grinding and polishing with a sandpaper wheel, subject to the ability to remove the superficial carbonized charred part of the wood;

[0054] S2: Configure coating slurry: the coating slurry is calculated in parts by weight, including: 8kg of natural lacquer, 4kg of vegetable wax, 70kg of vegetable oil, 2kg of rosin glycerin, and 8kg of additives;

[0055] S3: Apply the configured coating slurry on t...

Embodiment 3

[0071] A bathroom cabinet wood pretreatment process, comprising the following steps:

[0072] S1: Wood pretreatment: first place the wood in a cool and ventilated place to air-dry for 15 days, and then process the wood into boards of various specifications and thicknesses;

[0073] Use an acetylene cutting gun at a high temperature of 1500 degrees, and burn at a constant speed of 6 cm per second to open the hidden small cracks on the surface of the wood. The high-temperature flame can remove some burrs at the same time, making the wood texture clearer. Grinding and polishing with a sandpaper wheel, subject to the ability to remove the superficial carbonized charred part of the wood;

[0074] S2: Configure coating slurry: the coating slurry is calculated in parts by weight, including: 10kg of natural lacquer, 5kg of vegetable wax, 80kg of vegetable oil, 3kg of rosin glycerin, and 12kg of additives;

[0075] S3: Apply the configured coating slurry on the board processed in step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com