Cystoid type spherical nucleic acid and preparation method and application thereof

A spherical and vesicle technology, which is applied in the direction of pharmaceutical formulations, medical preparations with non-active ingredients, medical preparations containing active ingredients, etc., can solve the problem of not being able to carry chemical drugs and/or protein drugs at the same time, and achieve the goal of carrying High drug efficiency, simple process, and intracellular reduction-sensitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] A method for preparing vesicular spherical nucleic acid, comprising:

[0065] The PNIPAM-S-S-Py polymer is reacted with functionalized nucleic acid drugs to obtain a diblock complex capable of forming vesicular spherical nucleic acids.

[0066] The vesicular spherical nucleic acid of the present invention adopts PNIPAM-S-S-Py polymer to react with functionalized nucleic acid drug to obtain a diblock complex, and the diblock complex can be formed by self-assembly under the condition higher than the critical transition temperature LCST The vesicle-shaped spherical nucleic acid has a simple process and is suitable for large-scale production.

[0067] In a preferred embodiment of the present invention, the reaction of the PNIPAM-S-S-Py polymer with a functionalized nucleic acid drug to obtain a diblock complex includes:

[0068] The PNIPAM-S-S-Py polymer and the functionalized nucleic acid drug are reacted in a solvent to obtain a diblock complex.

[0069] The present inv...

Embodiment 1-3

[0112] A method for preparing vesicular spherical nucleic acid, comprising:

[0113] 1. NIPAM forms PNIPAM polymer through RAFT polymerization:

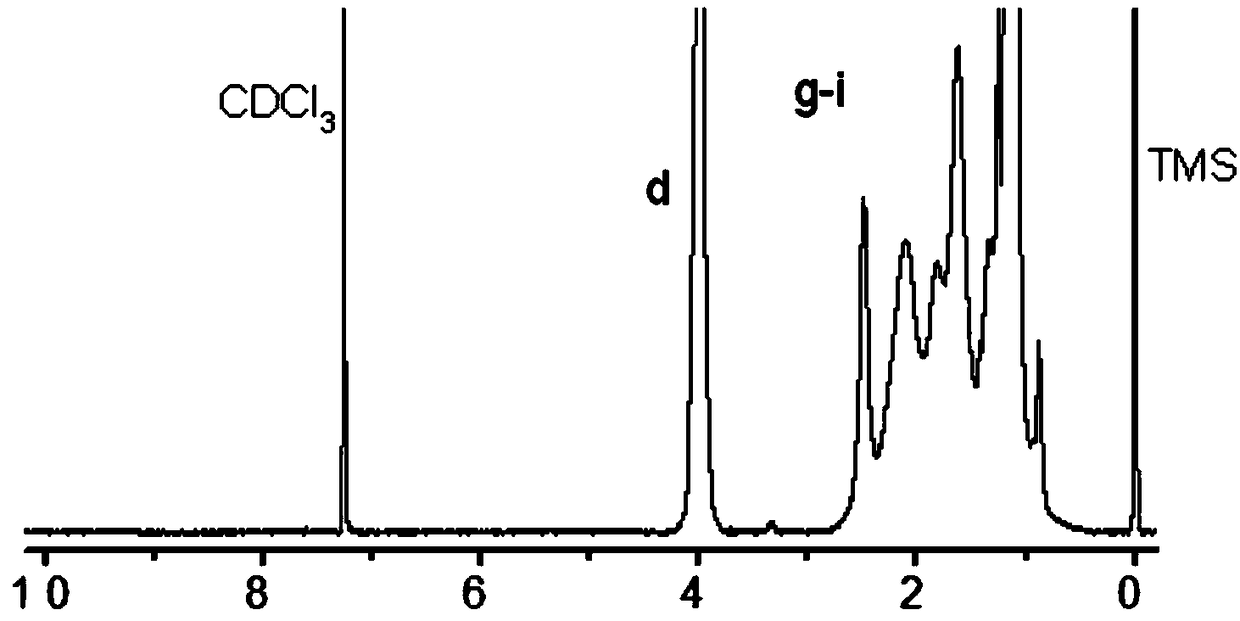

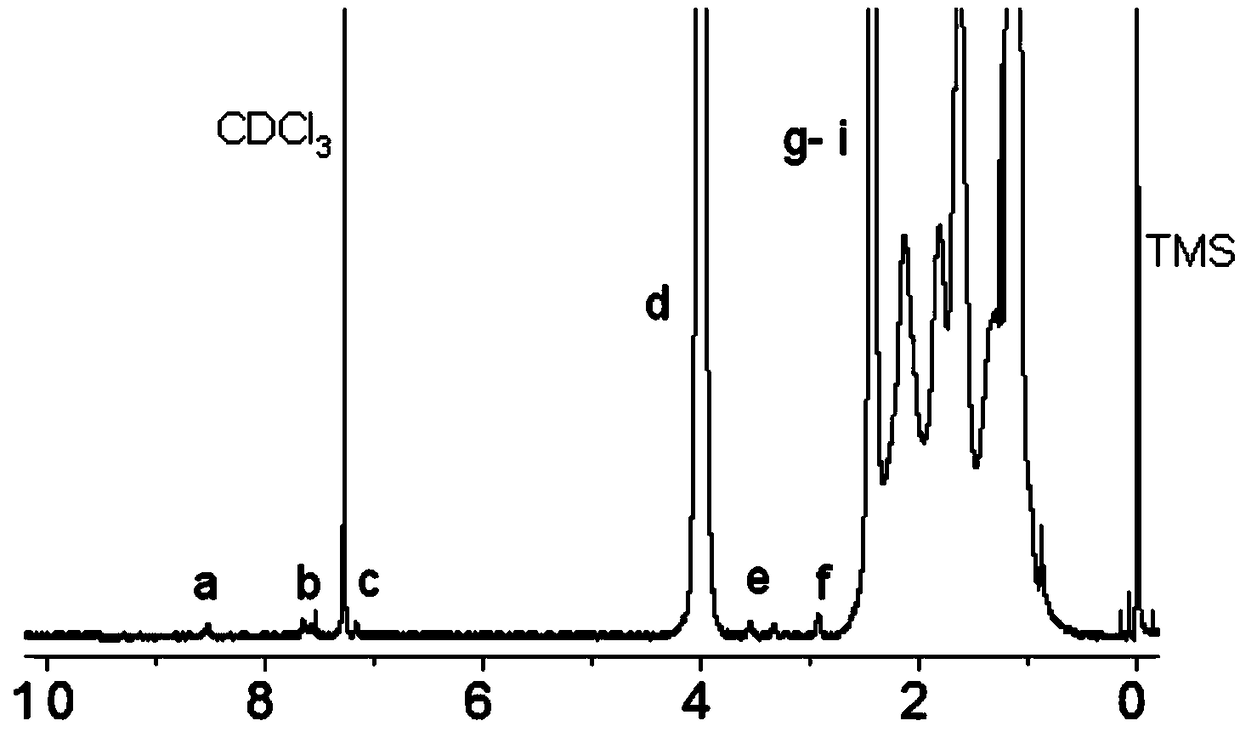

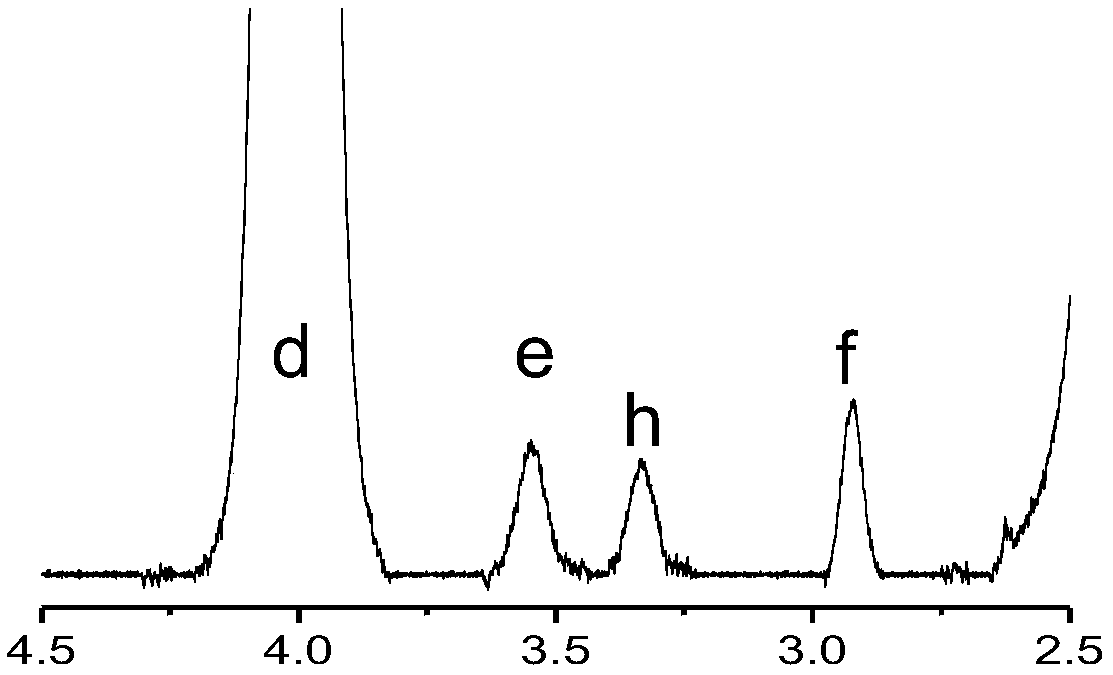

[0114] 1.1 NIPAM (isopropylacrylamide) (sigma) monomer, RAFT (Reversible Addition-Fragmentation Chain Transfer Polymerization) reagent (Bailingwei Technology), initiator AIBN (azobisisobutyronitrile) (Aladdin) Polymerization takes place at specific ratios (80:1:0.1, 150:1:0.2 and 200:1:0.3 respectively in Examples 1-3) (reaction temperatures in Examples 1-3 are respectively 65 ℃, 75 ℃ and 70 ℃, the reaction time of embodiment 1-3 is respectively 36h, 12h and 24h successively) generates PNIPAM polymer (the molecular weight Mn of embodiment 1-3 gained PNIPAM polymer is about 7000, 13000 respectively successively , 19000, respectively recorded as 7k, 13k and 19k).

[0115] Take the 19K polymer synthesis process as an example:

[0116] Prepare a 25mL or 50mL reaction tube, and first pass N through the double row tube 2 Purify for 30 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com