Potato nutrition recombinant rice recipe and preparation method thereof

A technology for recombining rice and potatoes, which is applied in the field of food deep processing, can solve the problems of complex production process, loss of nutritional components, short shelf life, etc., and achieve the effects of extending shelf life, improving texture characteristics, and improving processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

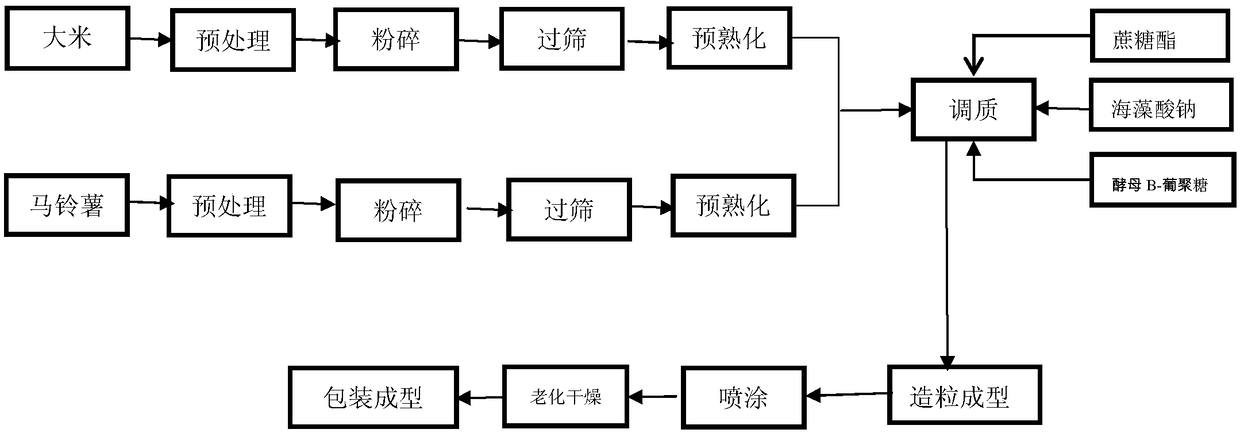

Method used

Image

Examples

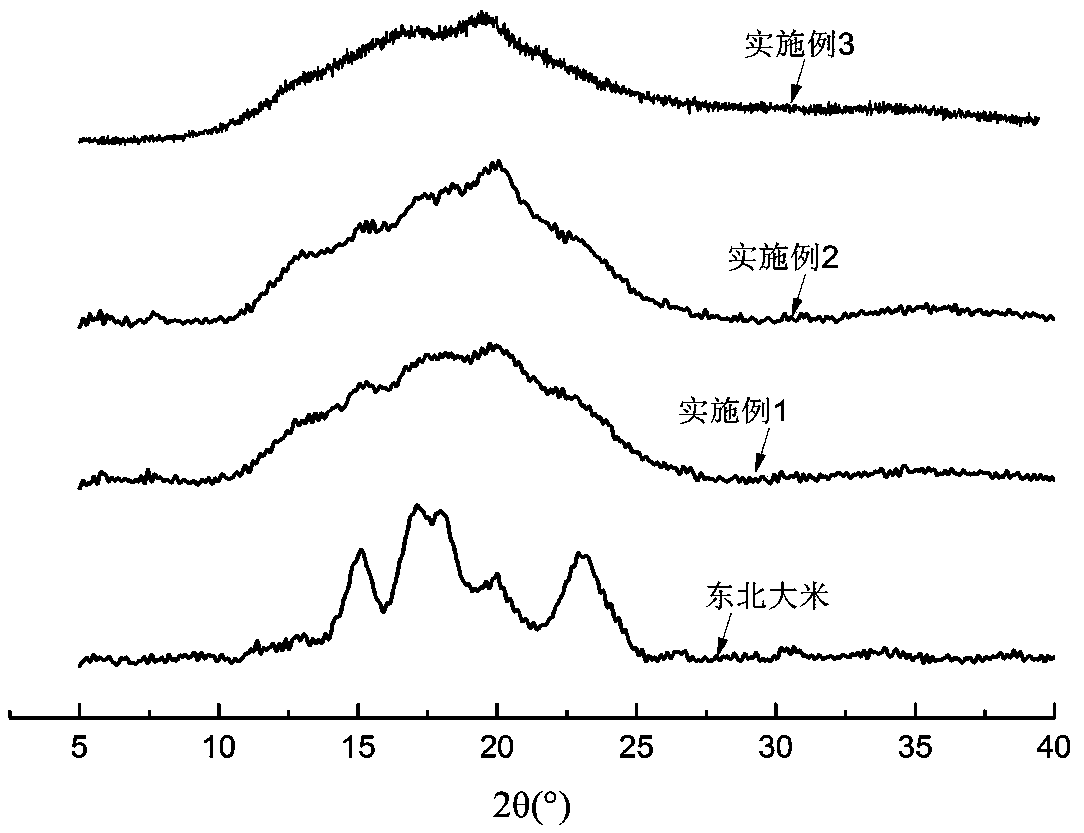

Embodiment 1

[0045] Accurately weigh 2700g of rice and 300g of whole potato flour, soak the rice for 1 hour, pre-cure the soaked rice by low-temperature extrusion (30°C in zone I, 40°C in zone II, 50°C in zone III, and 50°C in zone IV) Zone 60°C, Zone V 70°C); potatoes are pre-cooked after mashing with whole powder, the cooking temperature is 40°C, and the cooking time is 2 minutes. After the rice and potato flour were mixed and tempered, 3g of sucrose ester, 0.3g of yeast β-glucan and 7.5g of sodium alginate were prepared into a solution and added to the mixed powder of pre-cooked potato flour and rice flour, so that The moisture content of the material reaches 20%, and the material is sent into the twin-screw extruder for molding and granulation, and the working temperature of each section of the twin-screw extruder is set: 50°C for zone I, 80°C for zone II, and 120°C for zone III ℃, 110 ℃ in zone IV, 30 ℃ in zone V, the screw speed is 240rpm, extrude through a die with a circular die ho...

Embodiment 2

[0047] Accurately weigh 2400g of rice and 600g of whole potato powder, soak the rice for 2 hours, pre-cure the soaked rice by low-temperature extrusion (35°C in zone I, 45°C in zone II, 55°C in zone III, and 55°C in zone IV) Zone 65°C, Zone V 75°C); potatoes are cooked and pre-cooked after pulping, the cooking temperature is 50°C, and the cooking time is 3 minutes. After the rice and potato flour were mixed and tempered, 13.5g of sucrose ester, 0.9g of yeast β-glucan and 15g of sodium alginate were prepared into a solution and added to the mixed powder of pre-cooked potato flour and rice flour, so that The moisture content of the material reaches 25%, and the material is sent into the twin-screw extruder for molding and granulation, and the working temperature of each section of the twin-screw extruder is set: 55°C in zone I, 90°C in zone II, and 130°C in zone III ℃, 115℃ in zone IV, 35℃ in zone V, the screw speed is 260rpm, extrude through a die with a circular die hole diame...

Embodiment 3

[0049] Accurately weigh 2100g of rice and 900g of whole potato flour, soak the rice for 3 hours, pre-cure the soaked rice by low-temperature extrusion (40°C in zone I, 50°C in zone II, 60°C in zone III, and 60°C in zone IV) Zone 70°C, Zone V 80°C); potatoes are cooked and pre-cooked after pulping, the cooking temperature is 60°C, and the cooking time is 4 minutes. After the rice and potato flour were mixed and tempered, 22.5g of sucrose ester, 0.5g of yeast β-glucan and 30g of sodium alginate were prepared into a solution and added to the mixed powder of pre-cooked potato flour and rice flour, so that The moisture content of the material reaches 30%, and the material is sent into the twin-screw extruder for molding and granulation, and the working temperature of each section of the twin-screw extruder is set: 60°C for zone I, 100°C for zone II, and 140°C for zone III ℃, 120 ℃ in zone IV, 40 ℃ in zone V, the screw speed is 280rpm, extrude through a die with a circular die hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com