Efficient energy-saving heat-insulation brick and method for preparing same

A high-efficiency energy-saving, heat-insulating brick technology, applied in the field of building materials, can solve problems such as unsatisfactory use effect, consumption of effective resources, limited urban sludge, etc., to achieve the effects of improving heat preservation effect, solving environmental pollution, and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

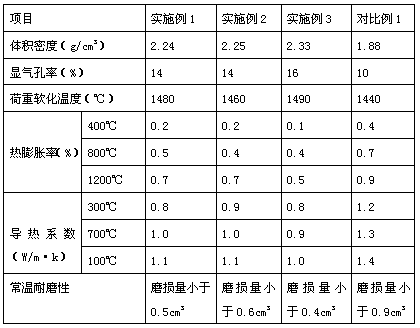

Embodiment 1

[0030] A high-efficiency energy-saving insulation brick, comprising the following raw materials in parts by weight: 35 parts of river sludge, 18 parts of coal gangue powder, 18 parts of palygorskite powder, 13 parts of brucite fiber, 20 parts of glass fiber, and 16 parts of modified alumina 6 parts, 6 parts of hydroxypropyl guar gum, 12 parts of ethylene glycol distearate, 9 parts of polycarboxylate superplasticizer, 13 parts of refractory oxide, 17 parts of styrene, 15 parts of porogen, compound 8 parts of additives and 26 parts of water.

[0031] A method for preparing high-efficiency energy-saving insulation bricks, comprising the following preparation steps:

[0032] a, coal gangue powder, palygorskite powder, brucite fiber and glass fiber are mixed, import in the shearing machine, shear and disperse 20min with the speed of 360r / min, obtain powder;

[0033] b. Import ethylene glycol distearate into the reaction kettle, heat up to 55°C, heat and stir for 12 minutes, then a...

Embodiment 2

[0042] A high-efficiency energy-saving insulation brick, comprising the following raw materials in parts by weight: 45 parts of river sludge, 18 parts of coal gangue powder, 18 parts of palygorskite powder, 13 parts of brucite fiber, 16 parts of glass fiber, and 15 parts of modified alumina 7 parts, 7 parts of hydroxypropyl guar gum, 12 parts of ethylene glycol distearate, 8 parts of polycarboxylate superplasticizer, 16 parts of refractory oxide, 14 parts of styrene, 19 parts of porogen, compound 8 parts of additives and 23 parts of water.

[0043] A method for preparing high-efficiency energy-saving insulation bricks, comprising the following preparation steps:

[0044] a, coal gangue powder, palygorskite powder, brucite fiber and glass fiber are mixed, import in the shearing machine, shear and disperse 20min with the speed of 340r / min, obtain powder;

[0045] b. Import ethylene glycol distearate into the reaction kettle, heat up to 58°C, heat and stir for 12 minutes, then a...

Embodiment 3

[0054] A high-efficiency energy-saving insulation brick, comprising the following raw materials in parts by weight: 44 parts of river sludge, 19 parts of coal gangue powder, 17 parts of palygorskite powder, 15 parts of brucite fiber, 18 parts of glass fiber, and 14 parts of modified alumina Parts, 9 parts of hydroxypropyl guar gum, 8 parts of ethylene glycol distearate, 6 parts of polycarboxylate superplasticizer, 19 parts of refractory oxide, 16 parts of styrene, 17 parts of porogen, compound 8 parts of additives and 23 parts of water.

[0055] A method for preparing high-efficiency energy-saving insulation bricks, comprising the following preparation steps:

[0056] a, coal gangue powder, palygorskite powder, brucite fiber and glass fiber are mixed, import in the shearing machine, shear and disperse 18min with the speed of 360r / min, obtain powder;

[0057] b. Introduce ethylene glycol distearate into the reaction kettle, heat up to 55°C, heat and stir for 12 minutes, then a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com