Dyeing liquor and dyeing method for reducing indigo blue through indirect electrochemistry of single solute

A dyeing method and electrochemical technology, applied in dyeing, textile and papermaking, etc., can solve the problems of low electron transfer efficiency, high energy consumption, low dyeing efficiency, etc., to speed up electrochemical reduction rate, improve current efficiency, ensure The effect of dyeing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

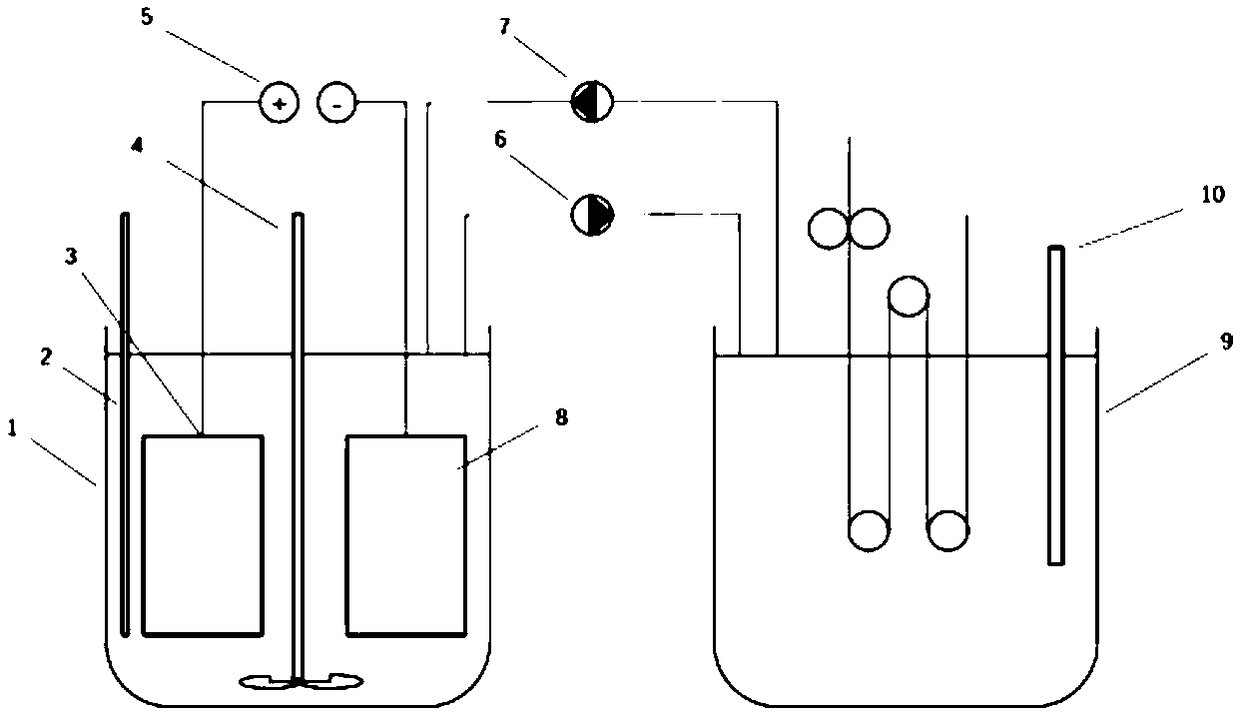

Image

Examples

Embodiment 1

[0021] A kind of method that uses the dye liquor of single solute indirect electrochemical reduction indigo to carry out dyeing, it comprises the steps:

[0022] The dyeing solution is placed in the electrolytic tank, the dyeing solution contains 0.01mol / L sodium hydroxide, 0.02mol / L 1,8-dihydroxyanthraquinone and 0.01mol / L indigo dye, the cathode is 20 mesh copper mesh, and the anode is 20 Stainless steel mesh, the electrolytic reduction temperature is 60°C, the electrolytic current density is 0.08 ampere / square decimeter, and the electrolytic solution is completely reduced to the reducing solution, and the reducing solution is introduced into the dyeing tank through the first pumping pump to dye the yarn. The dyeing process During every 20 minutes, the 1 / 2 volume part of the oxidized dye solution is pumped back into the electrolytic cell by the second suction pump, and the part of the oxidized reducing solution is electrochemically reduced in the electrolytic cell to realize ...

Embodiment 2

[0024] A kind of method that uses the dye liquor of single solute indirect electrochemical reduction indigo to carry out dyeing, it comprises the steps:

[0025] The dyeing solution is placed in the electrolytic tank, the dyeing solution contains 0.1mol / L sodium hydroxide, 0.05mol / L 2,6-dihydroxyanthraquinone, 0.03mol / L indigo dye, the cathode is 80 mesh stainless steel mesh, and the anode is 80 Nickel mesh, the electrolytic reduction temperature is 45°C, the electrolytic current density is 0.5 ampere / square decimeter, and the electrolyte is completely reduced to the reducing solution, and the reducing solution is introduced into the dyeing tank through the first pumping pump to dye the yarn. The dyeing process During every 20 minutes, the 1 / 2 volume part of the oxidized dye solution is pumped back into the electrolytic cell by the second suction pump, and the part of the oxidized reducing solution is electrochemically reduced in the electrolytic cell to realize reduction and ...

Embodiment 3

[0027] A kind of method that uses the dye liquor of single solute indirect electrochemical reduction indigo to carry out dyeing, it comprises the steps:

[0028] The dye solution is placed in an electrolytic tank, the dye solution contains 0.05mol / L sodium hydroxide, 0.002mol / L 2,6-dihydroxyanthraquinone, 0.01mol / L indigo dye, the cathode is a stainless steel sheet, and the anode is a copper sheet. The electrolytic reduction temperature is 40°C, the electrolytic current density is 2 amps / dm2, and when the electrolyte is completely reduced to a reducing solution, the reducing solution is introduced into the dyeing tank through the first pumping pump to dye the yarn. During the dyeing process, every After 20 minutes, 1 / 2 of the volume of the oxidized dye solution is pumped back to the electrolytic tank by the second pump, and the part of the oxidized reducing solution is electrochemically reduced in the electrolytic tank to realize reduction and inter-dyeing dye solution cycle, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com