Traditional archaistic style integrated roof tile

A roof tile, integrated technology, applied in the field of sintering tiles, can solve the problems of roof rain leakage, complicated operation, complicated production process, etc., and achieve the effects of preventing roof rain leakage, improving waterproof performance, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

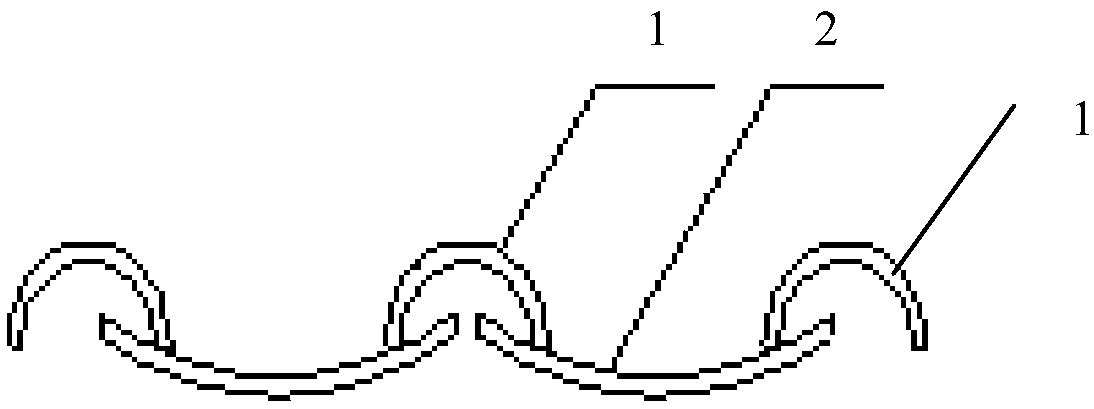

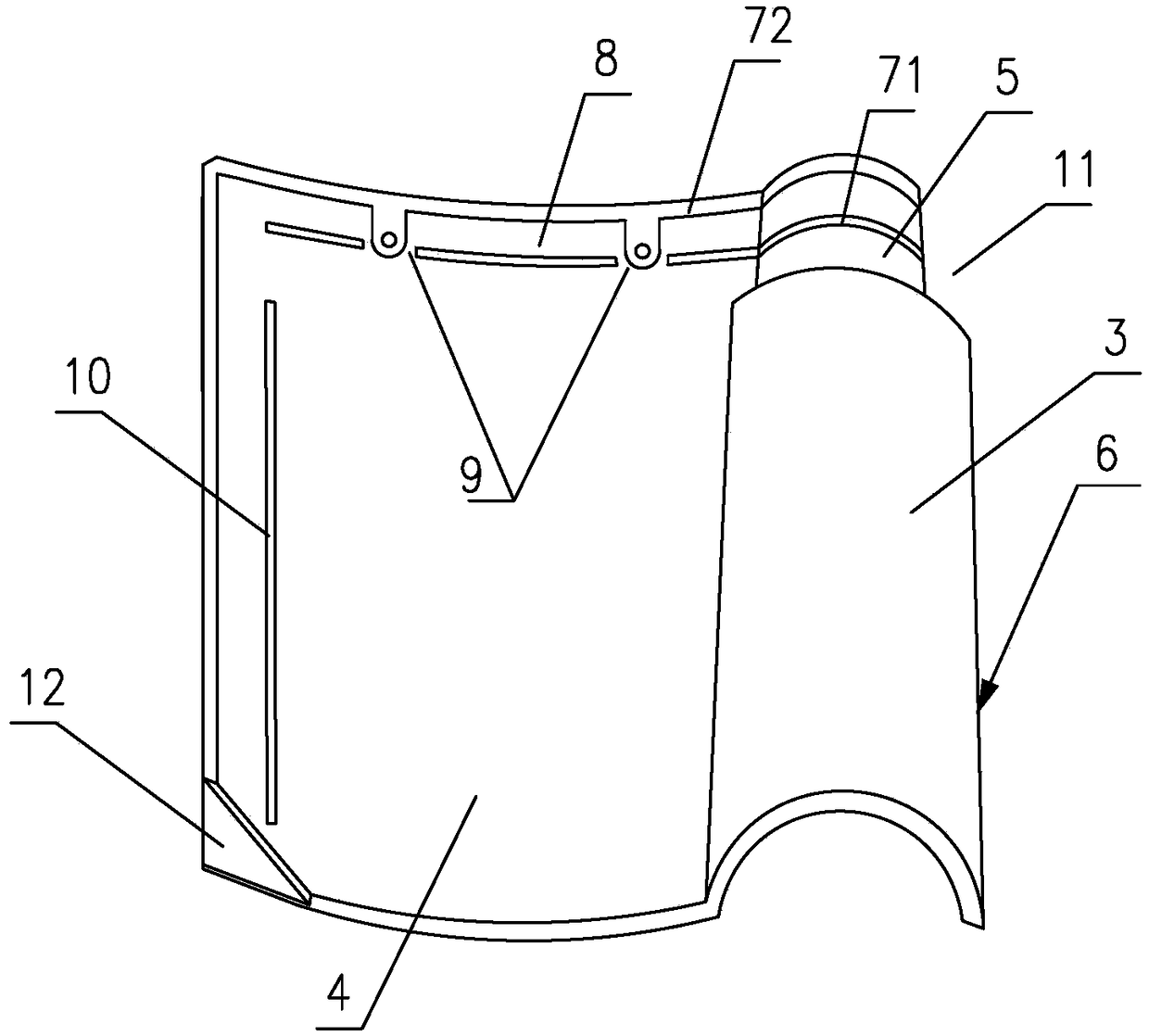

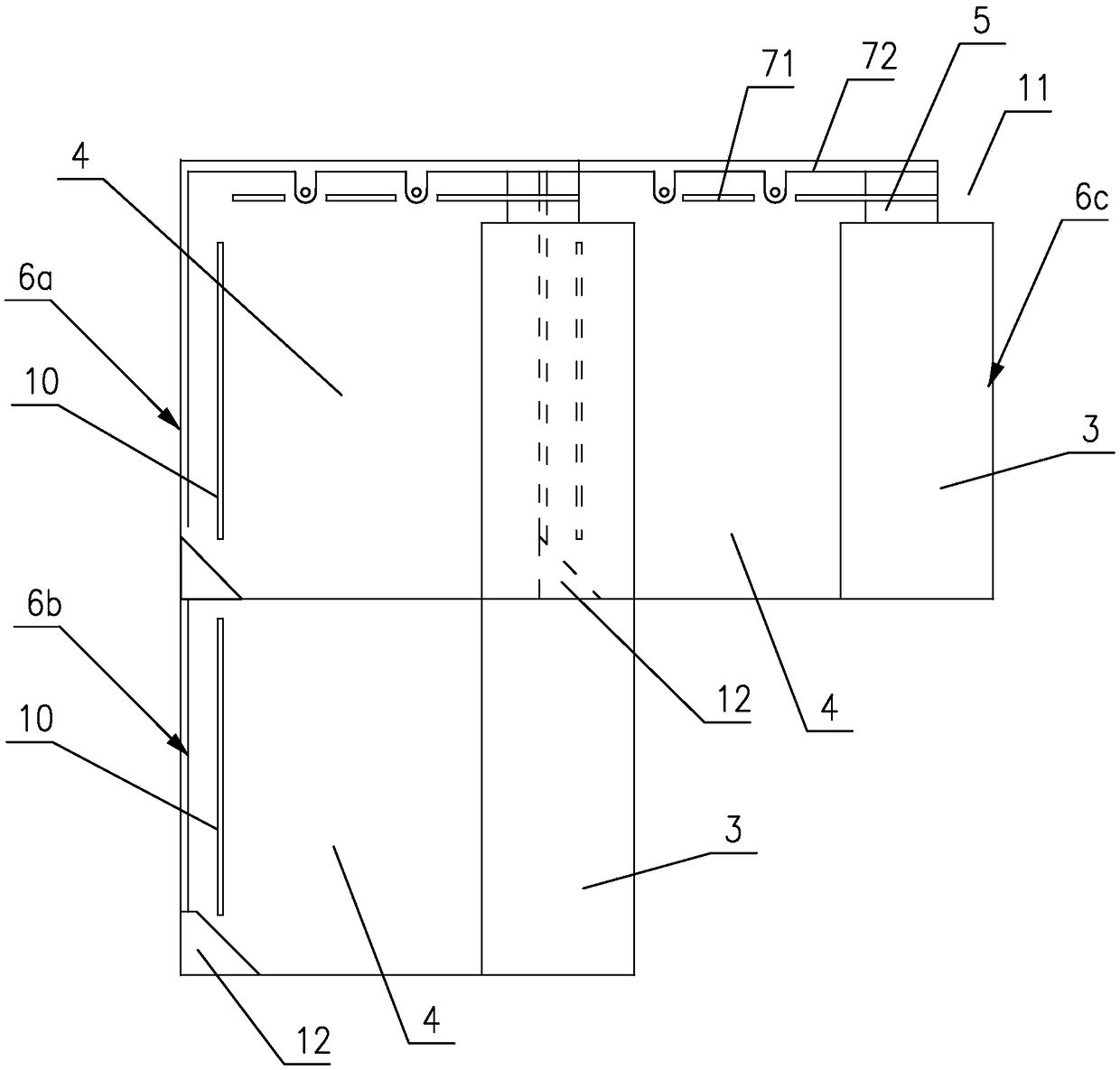

[0031] like Figure 4~6 As shown, it is a traditional antique-style integrated roof tile 6 of the present invention, which is mainly composed of peaks 3 and valleys 4 extending longitudinally. A plate-shaped body with a flat surface, the valley part 4 is a plate-shaped body whose upper surface is a concave arc-shaped surface, and the tail of the peak part 3 is provided with a sunken upward convex arc-shaped surface as the insertion surface 5 for insertion in the rear In the front ends of the peaks 3 of adjacent roof tiles 6 in the longitudinal direction, the height difference between the insertion surface 5 and the upper surface of the peaks 3 is the thickness of the peaks 3, so that the peaks of two adjacent roof tiles 6 in the longitudinal direction The upper surface of part 3 is flush with each other. The tail of the upper surface of the valley 4 is integrated with the insertion surface 5 , and the insertion surface 5 is arc-shaped and transitions to the tail of the upper ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com