Waterborne invisible fluorescent anti-counterfeiting ink as well as preparation method and application method thereof

An anti-counterfeiting ink and fluorescence technology, applied in the field of ink, can solve the problems of reducing the anti-counterfeiting effect, polluting the environment, hidden safety hazards, etc., achieving the effects of no explosion risk, increased anti-counterfeiting performance, and improved safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0058] The present invention also provides a preparation method of the above-mentioned water-based invisible fluorescent anti-counterfeiting ink, comprising the following steps:

[0059] The water-based invisible fluorescent anti-counterfeiting ink is obtained after mixing the water-based resin, the surfactant and the aqueous dye solution and performing ultrasonic treatment.

[0060] Wherein, the time of the ultrasonic treatment is 2-5 minutes, preferably 3 minutes.

[0061] The present invention also provides a method for using the above-mentioned water-based invisible fluorescent anti-counterfeiting ink, comprising the following steps:

[0062] Coating or printing the above-mentioned water-based invisible fluorescent anti-counterfeiting ink on the surface of the product and drying it to obtain the anti-counterfeiting product;

[0063] The traces and colors of the water-based invisible fluorescent anti-counterfeiting ink on the surface of the anti-counterfeiting product cann...

Embodiment 1

[0067] will have the structure:

[0068] (B1)

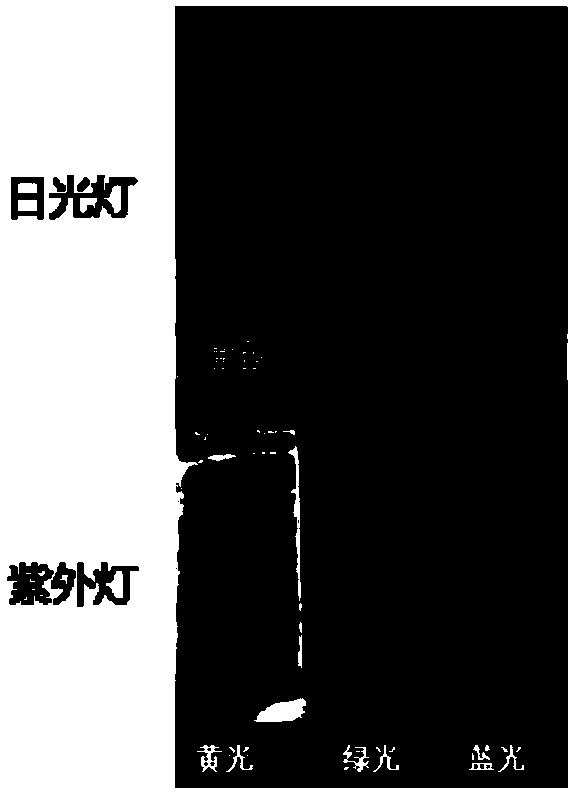

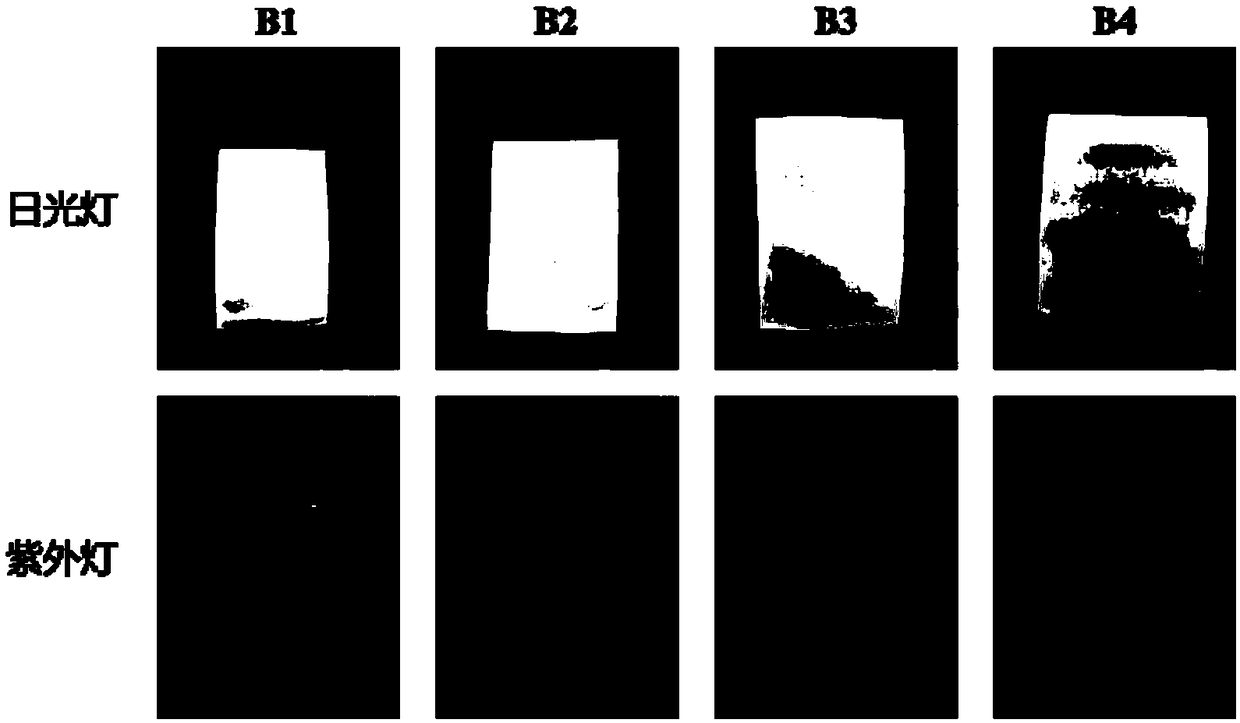

[0069] The aqueous dye solution (accounting for 10% of the total ink mass ratio, mass concentration 5g / L), aqueous acrylic resin aqueous solution (accounting for 87% of the total ink mass ratio), and polyvinylpyrrolidone (accounting for 3% of the total ink mass ratio) are mixed evenly Ultrasound for 3 minutes to obtain water-based invisible blue fluorescent anti-counterfeiting ink; apply it on cigarette packaging cardboard, after the water dries, the ink traces and colors on the cardboard cannot be seen under ordinary sunlight, and the cardboard will not be visible under the irradiation of ultraviolet light. showed strong blue fluorescence ( figure 1 with figure 2 ). Its emission wavelength is 435nm ( Figure 5 ), the quantum yield is 81%. figure 1 It is the photo of the water-based invisible fluorescent anti-counterfeiting ink of embodiments 1 to 3 under sunlight (top) and ultraviolet light (bottom), figure 2 It is the...

Embodiment 2

[0072] will have the structure:

[0073] (G1)

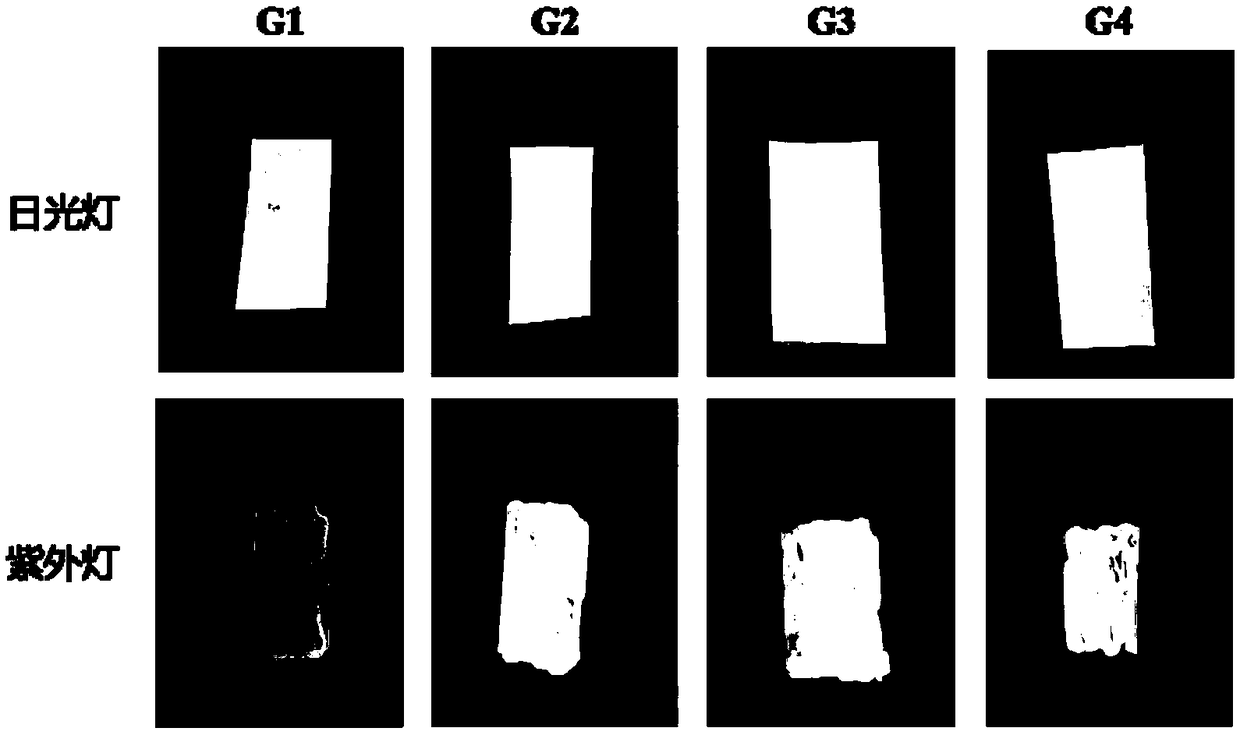

[0074] The aqueous dye solution (accounting for 10% of the total ink mass ratio, mass concentration 5g / L), aqueous acrylic resin aqueous solution (accounting for 87% of the total ink mass ratio), and polyvinylpyrrolidone (accounting for 3% of the total ink mass ratio) are mixed evenly Ultrasound for 3 minutes to obtain water-based invisible green fluorescent anti-counterfeiting ink; apply it on cigarette packaging cardboard, after the water dries, the ink traces and colors on the cardboard cannot be seen under ordinary sunlight, and under the irradiation of ultraviolet light, the cardboard will be show strong green fluorescence ( figure 1 with image 3 ). Its emission wavelength is 485nm ( Figure 5 ), the quantum yield is 88%. see figure 1 with image 3 , figure 1 It is the photo of the water-based invisible fluorescent anti-counterfeiting ink of embodiments 1 to 3 under sunlight (top) and ultraviolet light (bottom), ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com