Eucommia ulmoides seed oil powder electuary and preparation method thereof

A technology of Eucommia ulmoides seed oil and granules, applied in the field of powder oil processing, can solve the problems of unstable product quality, inability to precisely control the proportion of soybean oil in the core material and soybean protein in the wall material, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method of eucommia seed oil powder granules, comprising the steps of:

[0031] 1) Raw material pretreatment: Dry the eucommia samara with an electric blast drying oven until the water content is lower than 12%, peel off the husk of the eucommia samara, and use a micro-plant pulverizer to crush it to a particle size of 10-20 meshes to obtain the eucommia ulmoides Samara powder;

[0032] 2) Vacuum microwave heat treatment: Spray water on the surface of the eucommia samara powder obtained in step (1), while stirring continuously until the final water content of the eucommia samara powder is 25-35%, then transfer it to the cavity of the microwave oven, and Vacuum microwave treatment is carried out under the condition of vacuum degree of 0.90-0.98MPa and microwave dose of 1.5kw / kg, and the moisture content of Eucommia samara powder is controlled at 9%-12%;

[0033] 3) Oil extraction by supercritical extraction: using the eucommia samara powder obtained in step...

Embodiment 2

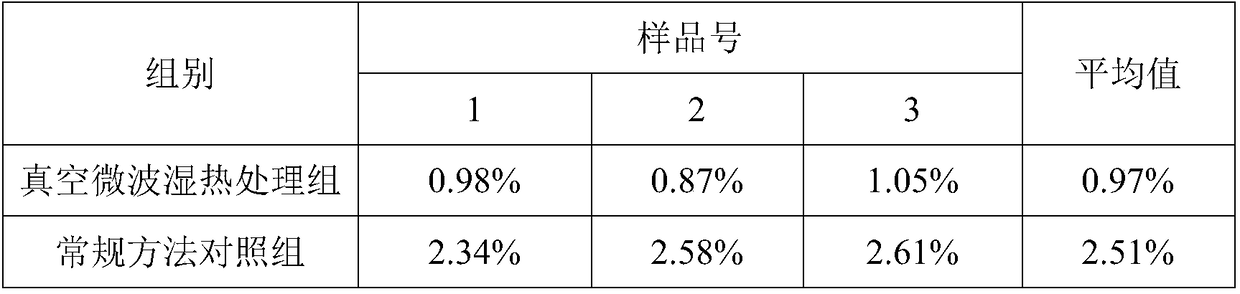

[0041] Determination of the effect of vacuum microwave heat treatment on the residual oil rate of supercritical extraction.

[0042] 1. Preparation of eucommia seed meal

[0043] Vacuum microwave wet heat treatment group: adopt the method of Example 1, take the Eucommia ulmoides seed meal obtained after supercritical extraction and oil extraction, and measure the residual oil rate;

[0044] Conventional method control group: adopt the method of Example 1, but without vacuum microwave heat treatment, take the Eucommia ulmoides seed meal obtained after supercritical extraction to measure the residual oil rate.

[0045] 2. Determination of residual oil rate

[0046] Three samples were taken from each group for testing, and the residual oil rate was determined by Soxhlet extraction method.

[0047] 3. Analysis of results

[0048] Table 1 Effect of vacuum microwave heat treatment on the residual oil rate of supercritical extraction

[0049]

[0050] It can be known from Tabl...

Embodiment 3

[0052] Determination of indicators such as embedding rate, fluidity, solubility, peroxide value, moisture content and the like of the eucommia seed oil powder granule of the present invention.

[0053] 1. Determination of embedding rate

[0054] Embedding rate=(1-surface oil content / total oil content)×100%

[0055] Determination of surface oil content of eucommia seed oil powder granules: using petroleum ether as a solvent, accurately weigh 5.0g eucommia eucommia seed oil powder granules, add 120mL petroleum ether in three times, shake fully each time, filter and combine the filtrates, and the filtrates are reduced After pressing and concentrating, the quality of the obtained oil is the surface oil content of the eucommia seed oil powder granule.

[0056] Determination of the total oil content of eucommia seed oil powder granules: use anhydrous ether as a solvent, accurately weigh 5.0 g of eucommia eucommia seed oil powder granules, add 150-180 mL of anhydrous ether, extract ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| peroxide value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com