Silica-coated silicone rubber particles and cosmetic

A technology of silicone rubber particles and silicon dioxide, applied in cosmetics, cosmetics, cosmetic preparations and other directions, can solve the problems of undisclosed, undisclosed silicone particles, and the shape and properties of the particles have not been specifically described, and achieves high sphericity, The effect of reduced contact surface area and reduced viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

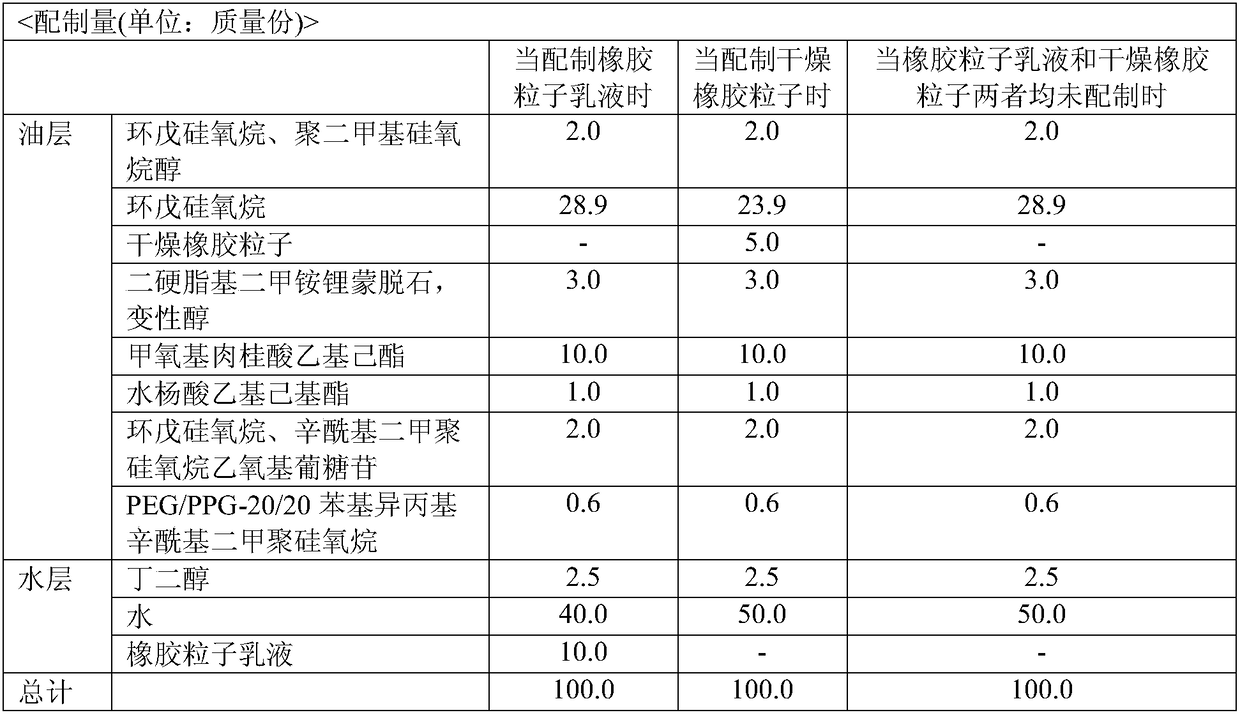

Embodiment 1

[0157] Oil-in-water silicone emulsion 1 was prepared as follows. First, 5 parts by mass of silica particles (A) were dispersed in 45 parts by mass of water by stirring the mixture at 4,000 rpm using ULTRA TURRAX T50 base shaft generator G45M manufactured by IKA to prepare a water dispersion of silica particles liquid. Next, in another container, 47.9 parts by mass of vinyl-containing polydimethylsiloxane (I) (both ends of which are blocked by dimethylvinylsilyl groups and have a viscosity of 200 mPa·s (25 ℃)) and 2.1 parts by mass of methylhydrogenpolysiloxane (II) having SiH groups in the side chain (both ends of the molecular chain are blocked by trimethylsiloxy groups and the viscosity is 65mPa·s (25°C )). Accordingly, a mixed oil in which the NH / NA ratio between the number of alkenyl groups (NA) and the number of hydrogen atoms bonded to silicon atoms (NH) was 1.2 / 1 was prepared. Next, the prepared mixed oil was added to the aqueous dispersion of silica particles under ...

Embodiment 2

[0161]Silicone rubber particle dispersion emulsion and silicone rubber particles were obtained in the same manner as in Example 1, except that, in the silicone emulsion in Example 1, 49.0 parts by mass of Vinyl polydimethylsiloxane (I) and 1.0 parts by mass of methylhydrogen polysiloxane (II) were mixed to prepare the number of alkenyl groups (NA) and the number of hydrogen atoms bonded to silicon atoms (NH ) ratio NH / NA is 1.5 / 1 mixed oil. The obtained silica-coated silicone rubber particles comprise silicone rubber particles and a silica coating layer which completely or partially coats the surface of the silicone rubber particles.

[0162] The particle diameter of the obtained silicone rubber particle dispersion emulsion was measured by a Beckman Coulter LS230 (manufactured by Beckman Coulter Corporation). Therefore, it was confirmed that the median diameter d50 was 11 μm.

Embodiment 3

[0164] Silicone rubber particle dispersion emulsion and silicone rubber particles were obtained in the same manner as in Example 1, except that the amount of silica particles of component (A) in the silicone emulsion 1 of Example 1 was 3.0 parts by mass, The rest is water. The obtained silica-coated silicone rubber particles comprise silicone rubber particles and a silica coating layer which completely or partially coats the surface of the silicone rubber particles.

[0165] The particle diameter of the obtained silicone rubber particle dispersion emulsion was measured by a Beckman Coulter LS230 (manufactured by Beckman Coulter Corporation). Therefore, it was confirmed that the median diameter d50 was 11 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| coating mass | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com