A kind of refining method of polyol ester crude product

A technology of polyol ester and refining method, which is applied to the preparation of carboxylic acid ester, chemical instruments and methods, and the preparation of organic compounds, etc., which can solve the problem of not meeting the quality requirements of synthetic refrigerator lubricating oil base oil and the yield of refined ester products low, waste lye polluting the environment and other issues, to achieve the effects of short heating time, intact molecular structure, and short operating time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

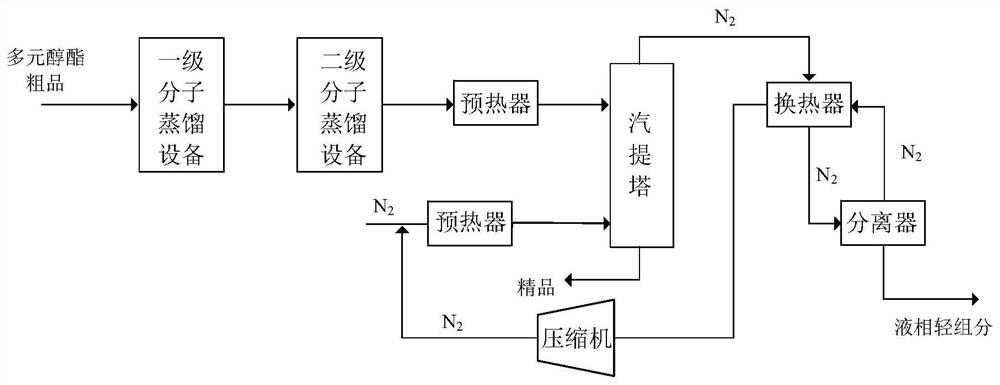

[0036] In this embodiment, the esterification product generated by the esterification reaction of pentaerythritol and isooctanoic acid under the action of a catalyst is used as the crude polyol ester raw material; the process flow of the refining method is as follows figure 1 As shown, the refining steps are as follows:

[0037] 1. Primary molecular distillation

[0038] Add 1L of the raw material of the above-mentioned polyol ester crude product to a primary molecular distillation device (such as a primary molecular distillation apparatus) to carry out primary molecular distillation, wherein the temperature of the primary molecular distillation is controlled to be 170° C., and the absolute pressure is 10 Pa, so that the multiple Moisture, catalysts with lower boiling points and unreacted isooctanoic acid in the crude alcohol ester raw material are removed.

[0039] 2. Secondary molecular distillation

[0040] The heavy component obtained by the primary molecular distillatio...

Embodiment 2

[0047] In this embodiment, the esterification product generated by the esterification reaction of pentaerythritol and isooctanoic acid under the action of a catalyst is used as the crude polyol ester raw material, and the refining steps are as follows:

[0048] 1. Primary molecular distillation

[0049] Add 1L of the above crude polyol ester raw material to primary molecular distillation equipment for primary molecular distillation, wherein the temperature of the primary molecular distillation is controlled to be 180° C., and the absolute pressure is 1 Pa, so that the moisture in the crude polyol ester raw material, Catalysts with lower boiling points and unreacted isooctanoic acid are removed.

[0050] 2. Secondary molecular distillation

[0051] Add the heavy component obtained from the primary molecular distillation to the secondary molecular distillation equipment for secondary molecular distillation, wherein the temperature of the secondary molecular distillation is cont...

Embodiment 3

[0058] In this embodiment, the esterification product generated by the esterification reaction of pentaerythritol and isooctanoic acid under the action of a catalyst is used as the crude polyol ester raw material, and the refining steps are as follows:

[0059] 1. Primary molecular distillation

[0060] Add 1L of the above crude polyol ester raw material to primary molecular distillation equipment for primary molecular distillation, wherein the temperature of the primary molecular distillation is controlled to be 175° C., and the absolute pressure is 5 Pa, so that the moisture in the crude polyol ester raw material, Catalysts with lower boiling points and unreacted isooctanoic acid are removed.

[0061] 2. Secondary molecular distillation

[0062] Add the heavy component obtained from the primary molecular distillation to the secondary molecular distillation equipment for secondary molecular distillation, wherein the temperature of the secondary molecular distillation is cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| relative humidity | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com