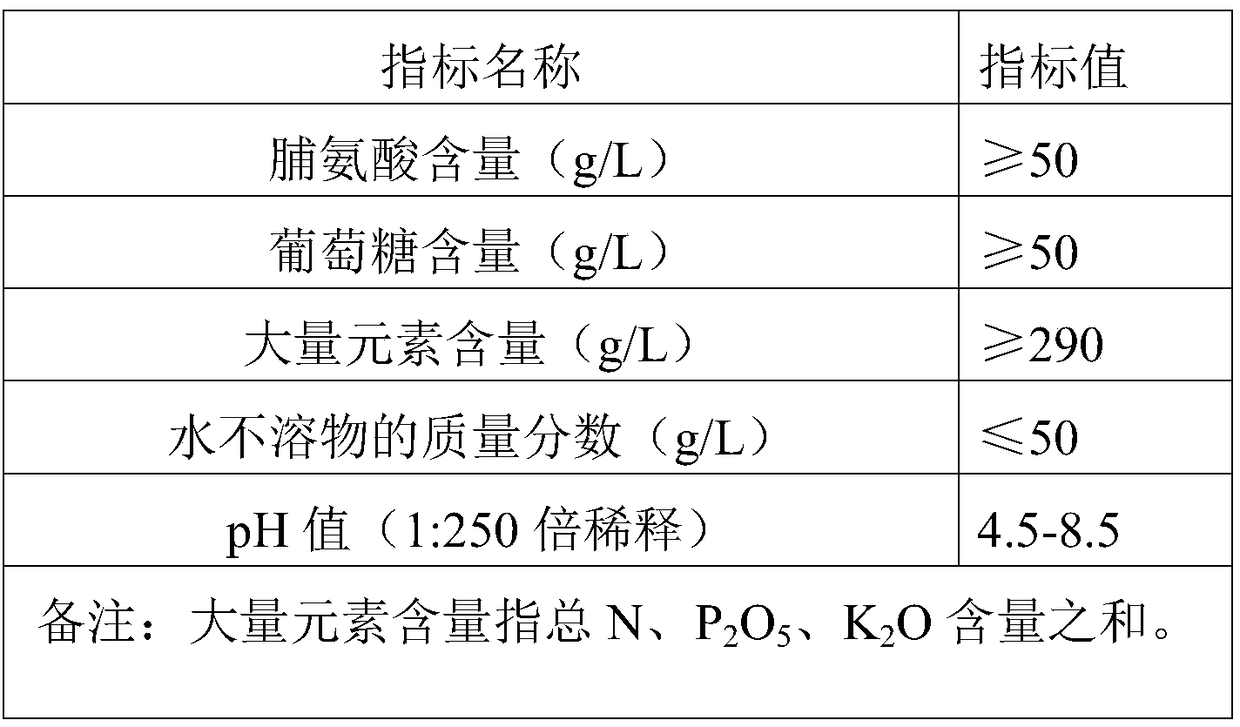

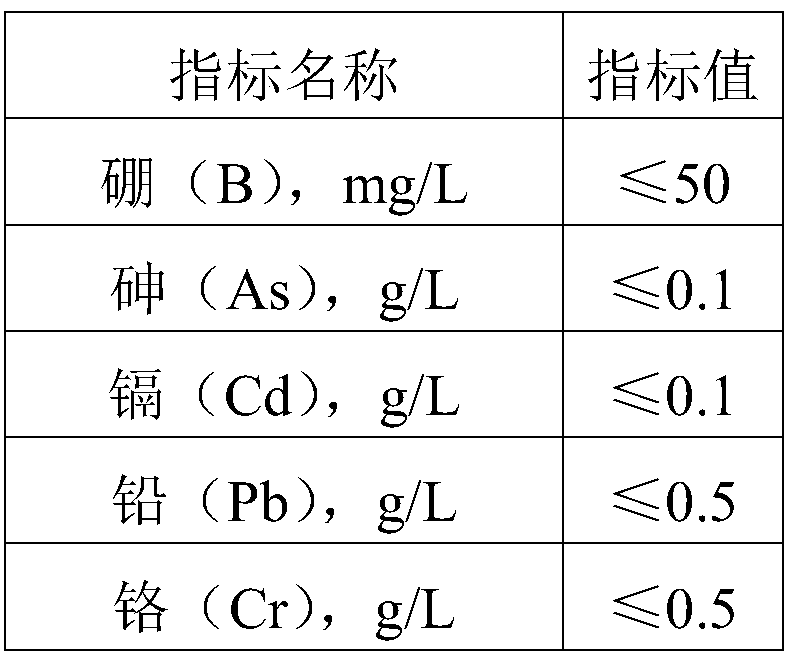

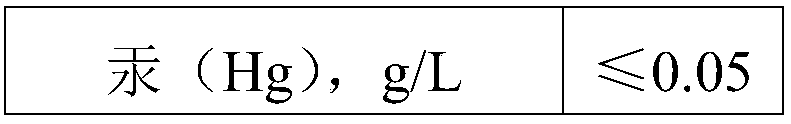

High-phosphorus multifunctional suspended liquid fertilizer containing amino acid and preparation method of liquid fertilizer

A multi-functional, amino acid technology, applied in the direction of phosphate fertilizer, liquid fertilizer, ammonium nitrate fertilizer, etc., can solve the problems of cumbersome process, high equipment requirements, high production cost, etc., and achieve the effect of simple production process, improved quality and quick results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] The preparation method of the above-mentioned amino acid-containing high-phosphorus multifunctional suspension liquid fertilizer comprises the following steps:

[0028] (1) Potassium pyrophosphate, boric acid, zinc nitrate, proline, glucose, urea ammonium nitrate, ammonium polyphosphate, EDTA-Fe, suspending agent, humectant and plant extract are weighed respectively by weight and number ratio;

[0029] (2) In the reactor, add the plant extract earlier,

[0030] (3) Heat to 50-60°C, add potassium pyrophosphate, boric acid, zinc nitrate, stir to dissolve;

[0031] (4) After cooling, add proline and glucose and stir until completely dissolved;

[0032] (5) Then add urea ammonium nitrate and ammonium polyphosphate and stir until the solution is clear;

[0033] (6) Finally, add EDTA-Fe, humectant, and suspending agent, stir evenly and set the volume to obtain a high-phosphorus multifunctional suspension liquid fertilizer containing amino acids.

Embodiment 1

[0035] The preparation method of the high-phosphorus multifunctional suspension type liquid fertilizer 1 containing amino acid comprises the following steps:

[0036] 1) Take by weighing 100 parts of potassium pyrophosphate, 5 parts of boric acid, 5 parts of zinc nitrate, 50 parts of proline, 50 parts of glucose, 130 parts of urea ammonium nitrate, 300 parts of Ammonium polyphosphate with a degree of polymerization of 5-18, 100 parts of EDTA-Fe, 20 parts of suspending agent, 20 parts of humectant and 300 parts of tea extract, the preparation method of tea extract: mix every 100 grams of tea The dry sample is boiled in 1L of boiling water at 100°C for 15 minutes, and then prepared after cooling to obtain a tea extract, wherein the content of the extract in the tea extract is 50-70%.

[0037] (2) In the reactor, add tea extract earlier,

[0038] (3) Heat to 50-60°C, add potassium pyrophosphate, boric acid, zinc nitrate, stir to dissolve;

[0039] (4) After cooling, add proline...

Embodiment 2

[0048] The fertilizer preparation method of the present embodiment is basically the same as that of Example 1, except that the formula content is different:

[0049] The formula of high-phosphorus multifunctional suspension liquid fertilizer 2 containing amino acid is: 120 parts of potassium pyrophosphate, 4 parts of boric acid, 6 parts of zinc nitrate, 60 parts of proline, 40 parts of glucose, 100 parts of urea nitrate Ammonium, 330 parts of ammonium polyphosphate with a polymerization degree of 5 to 18, 110 parts of EDTA-Fe, 15 parts of suspending agent, 25 parts of humectant and 400 parts of tea extract, the preparation method of tea extract: mix each 100 grams of dried tea leaves are boiled in 1 L of boiling water at 100° C. for 15 minutes, and then prepared after cooling to obtain a tea extract, wherein the content of the extract in the tea extract is 50-70%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com