Automated magnetic field-aided finishing machining device and method

A finishing and magnetic field-assisted technology, which is applied in the direction of manufacturing tools, grinding workpiece holders, manipulators, etc., can solve the problems of time-consuming, difficult to guarantee the processing quality, laborious and other problems, and achieve the goal of improving work efficiency and finishing processing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

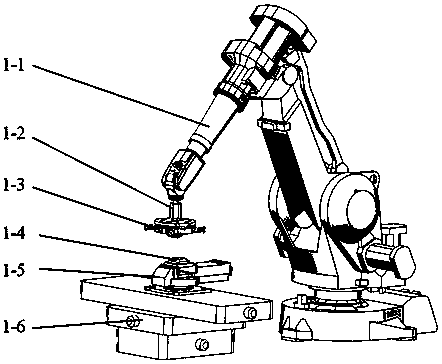

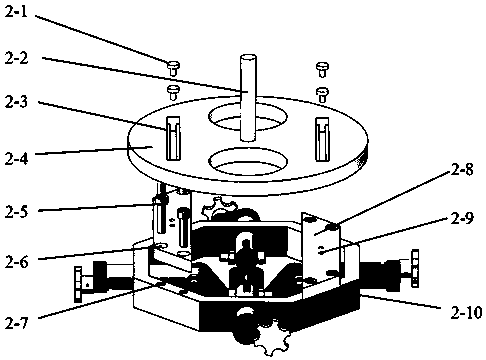

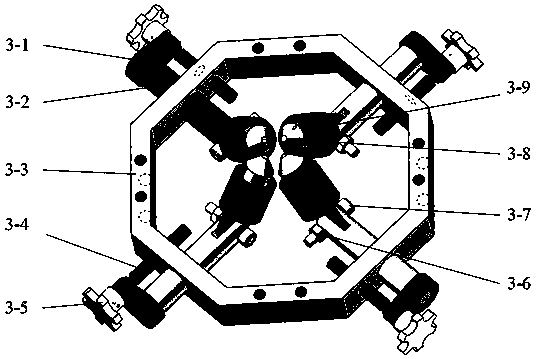

[0020] Specific implementation mode one: combine figure 1 , figure 2 and image 3 Explain that the device described in this embodiment includes an industrial robot 1-1, an industrial vibration motor 1-2, a new finishing device 1-3, a workpiece clamping device 1-5, and a three-axis precision displacement table 1-6. Finishing processing device 1-3 comprises magnetic field generating device 2-10, fixed plate 2-8, connecting plate 2-4, guide screw 2-1 and connecting rod 2-2, and magnetic field generating device 2-10 comprises connecting rod 3- 1. Guide rod 3-2, yoke 3-3, screw mandrel 3-4, handle 3-5, nut 3-6, bolt 3-7, four magnetic poles 3-8 and magnetic pole cover 3-9, the One end of the industrial vibration motor 1-2 is connected to the end of the industrial robot 1-1, and the other end is connected to the new finishing device 1-3, and the workpiece clamping device 1-5 is fixed on the three-axis precision displacement table 1-6. The processed parts 1-4 are placed on the wo...

specific Embodiment approach 2

[0021] Specific implementation mode two: combination figure 1 It is explained that the industrial robot 1-1 in this embodiment has six degrees of freedom, and can realize the high-speed rotational motion of the novel finishing device 1-3 and the multi-degree-of-freedom control of complex curved surface finishing. The industrial robot can be ABB IRB2400 robot with a payload of 7-20 kg and a maximum working range of 1810 mm, and the others are the same as in the first embodiment.

specific Embodiment approach 3

[0022] Specific implementation mode three: combination figure 1 It is explained that the industrial vibration motor 1-2 in this embodiment provides auxiliary vibration to the new finishing processing device 1-3 during finishing processing, so as to improve processing efficiency. The vibration frequency of the vibration motor can be selected as 50 Hz, and the others are the same as those in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com