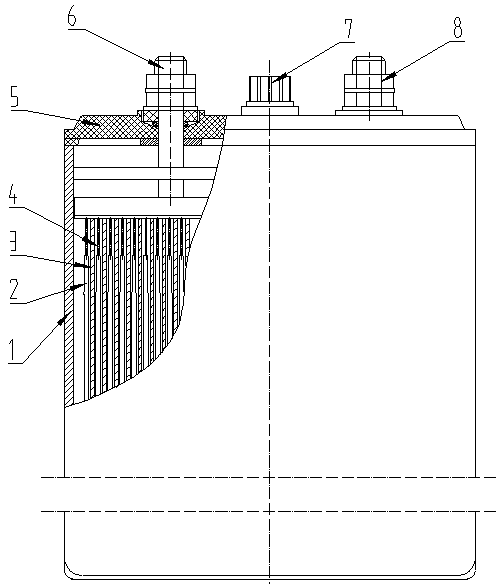

Large-capacity double-bag type iron-nickel battery

An iron-nickel battery, double-pocket technology, applied in the field of large-capacity double-pocket iron-nickel batteries, can solve the problems of short cycle life, poor rate performance, and low specific energy, and achieve long cycle life, capacity performance and rate performance Excellent, low internal resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

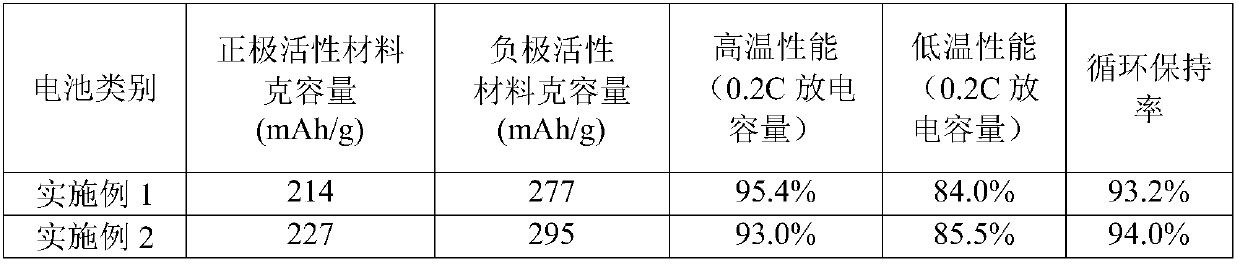

Embodiment 1

[0021] [Ni 0.8 Al 0.2 co 0.05 (OH) 2 ]·[(BO 2 - ) z mH 2O] Preparation of positive electrode active material:

[0022] First, the nickel chloride compound is made into a nickel salt solution with a molar concentration of 1.8mol / L with deionized water that removes carbon dioxide, and aluminum sulfate and cobalt sulfate are dissolved in a ratio of 0.8:0.2:0.05 in the molar ratio of nickel, aluminum and cobalt elements. In the sodium hydroxide solution with a molar concentration of 4mol / L, under the protection of inert gas nitrogen, slowly add the nickel salt solution dropwise into the reaction kettle equipped with the composite alkaline solution, the reaction temperature is 55 ° C, and the final reaction of the mixture is completed. pH=10.5, after the reaction is completed, age the mother liquor at 55°C for 36 hours, then filter; dry the filter cake at 125°C for 2 hours, and grind it into powder, pass through a 200-mesh sieve for later use, transfer 8g of the obtained pow...

Embodiment 2

[0031] [Ni 0.9 Al 0.1 Ca 0.05 (OH) 2 ]·[(CO 3 2- ) z mH 2 O] Preparation of positive electrode active material:

[0032] Firstly, nickel sulfate is made into a nickel salt solution with a molar concentration of 2.0mol / L with deionized water, and aluminum sulfate and calcium chloride are dissolved in a molar ratio of 0.9:0.1:0.05 with a molar concentration of 5mol. / L of sodium hydroxide solution, slowly drop the nickel salt solution into the reaction kettle equipped with the composite alkaline solution, the reaction temperature is 55°C, the pH of the final reaction mixture is 10.5, after the reaction is completed, the The mother liquor was aged for 36 hours under the conditions, and then filtered; the filter cake was dried at 125°C for 1 hour, and ground into powder, and passed through a 200-mesh sieve to obtain Ni 0.9 Al 0.1 Ca 0.05 (OH) 2 ]·[(CO 3 2- ) z mH 2 O powder samples.

[0033] will Ni 0.9 Al 0.1 Ca 0.05 (OH) 2 ]·[(CO 3 2- ) z mH 2 O adopts th...

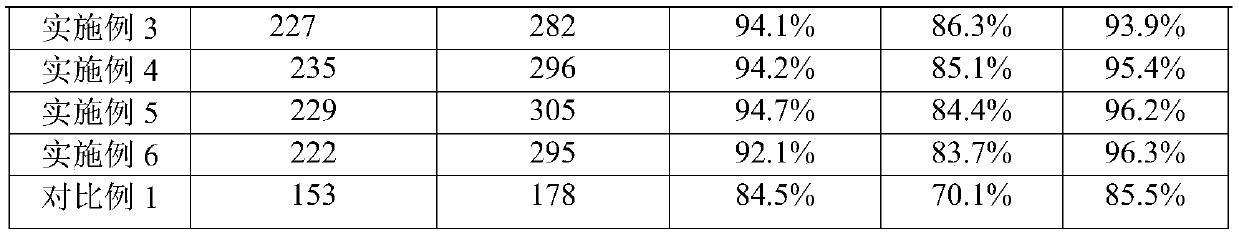

Embodiment 3

[0041] [Ni 0.7 Al 0.3 Y 0.05 (OH) 2 ]·[(Cl - ) z mH 2 O] Preparation of positive electrode active material:

[0042] First, the nickel chloride compound is made into a nickel salt solution with a molar concentration of 2.0 mol / L with deionized water that removes carbon dioxide, and the ratio of aluminum chloride and yttrium chloride to the molar ratio of nickel, aluminum, and yttrium is 0.7:0.3:0.05 Dissolve it in a sodium hydroxide solution with a molar concentration of 3mol / L. Under the protection of inert gas nitrogen, slowly add the nickel salt solution dropwise into the reaction kettle equipped with a composite alkaline solution. The reaction temperature is 60°C, and the final reaction is completed. The pH of the mixture is 11. After the reaction is completed, the mother liquor is aged at 70°C for 48h, and then filtered; the filter cake is dried at 125°C for 2h, and ground into powder to obtain [Ni 0.7 Al 0.3 Y 0.05 (OH) 2 ]·[(Cl - ) z mH 2 O] Powder samples....

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com