Preparation method of lithium iron phosphate-based modified positive electrode material

A technology of lithium iron phosphate and positive electrode materials, which is applied in the direction of battery electrodes, structural parts, electrical components, etc., can solve the problems of reducing the stacking density of lithium iron phosphate materials, and achieve improved electrochemical performance, increased conductivity, and reduced resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

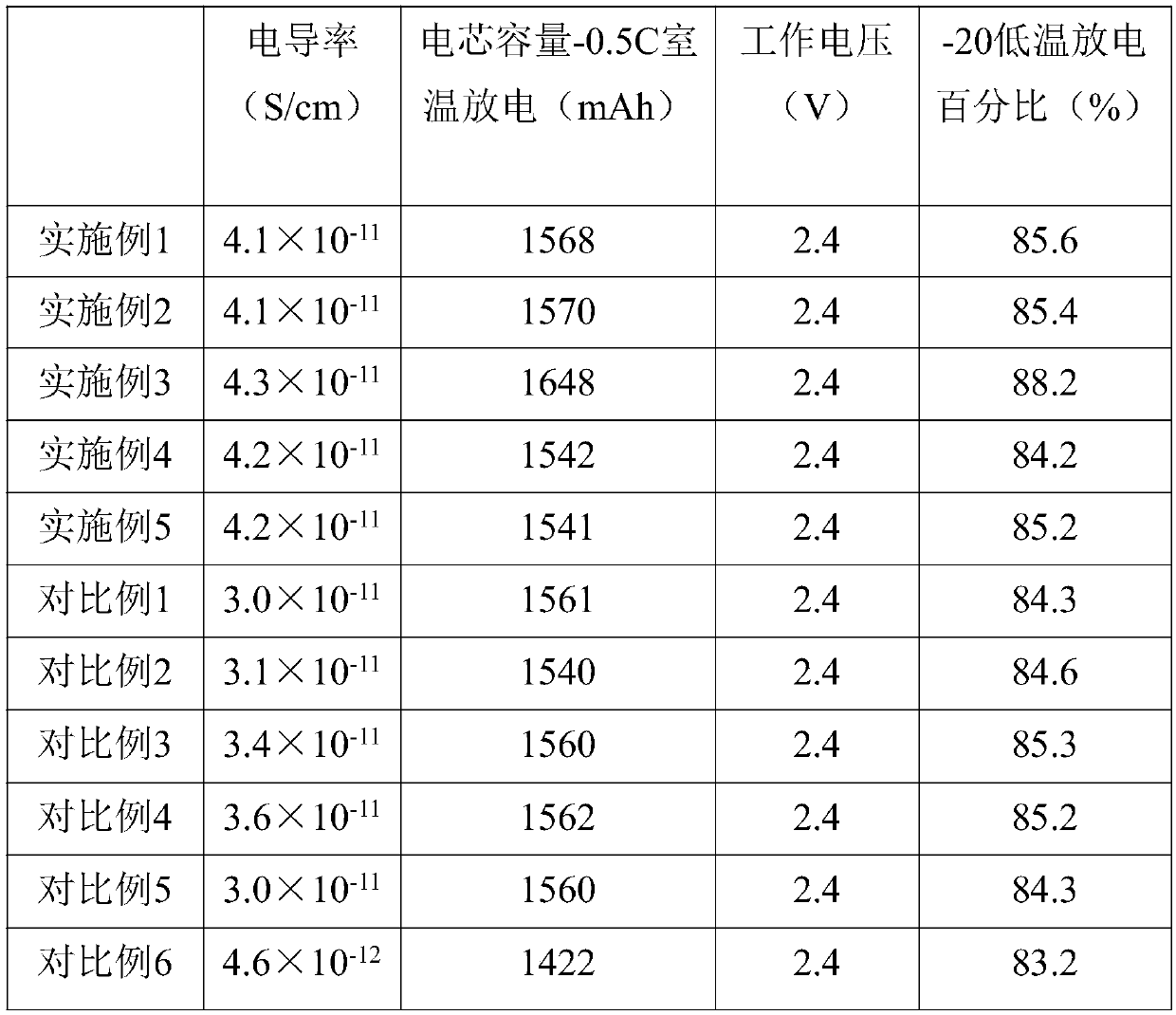

Examples

Embodiment 1

[0023] A method for preparing a lithium iron phosphate-based modified cathode material, comprising the following steps:

[0024] (1) Put the zirconium source compound into distilled water, and pulverize it by a ball mill until the particle size is 2-12um, then mix and stir at room temperature for 4-6 minutes to obtain the mixed solution A;

[0025] (2) Graphene and carbon nanotubes with a mass ratio of 2:1 were put into distilled water, and after being preliminarily pulverized by ultrasonic waves, they were mixed and stirred at room temperature for 4 to 6 minutes, and then 2 to 4 Raise the temperature to 40-60°C at a rate of ℃ / min, keep it warm for 4-6 hours, and then naturally cool to room temperature to obtain the mixed solution B;

[0026] (3) Mix and stir the mixed solution A and the mixed solution B at a volume ratio of 1:1 to obtain a zirconium-doped carbon material precursor, and pass the zirconium-doped carbon material precursor through a closed-cycle spray dryer For ...

Embodiment 2

[0034] The content of this embodiment is basically the same as that of Example 1, and the similarities will not be repeated. The difference is that in the step (3), the mixed solution A and the mixed solution B are mixed and stirred at a volume ratio of 2:1. , to obtain a zirconium-doped carbon material precursor, and dry the zirconium-doped carbon material precursor through a closed cycle spray dryer, the inlet temperature and outlet temperature of the closed cycle spray dryer are 800-960 °C and 70-60°C, the rotation speed of the atomizer of the closed-cycle spray dryer is 24000-26000r / min, and the zirconium-doped carbon material is formed.

Embodiment 3

[0036] The content of this embodiment is basically the same as that of Example 1, and the similarities will not be repeated. The difference is that in the step (3), the mixed solution A and the mixed solution B are mixed and stirred at a volume ratio of 1.5:1. , to obtain a zirconium-doped carbon material precursor, and dry the zirconium-doped carbon material precursor through a closed cycle spray dryer, the inlet temperature and outlet temperature of the closed cycle spray dryer are 800-960 °C and 70-60°C, the rotation speed of the atomizer of the closed-cycle spray dryer is 24000-26000r / min, and the zirconium-doped carbon material is formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com