Preparation method for negative material of high-power lithium ion power battery, negative material and application

A negative electrode material, power battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as unfavorable industrialized production, complex reaction conditions, and many reaction raw materials, and achieve benefits for industrialized production, simple reaction conditions, and environmental protection. Effects with low ambience requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A preparation method of a high-power lithium-ion power battery negative electrode material, comprising the following steps:

[0029] Step S1: Add 0.075gLiOH·H 2O. Pour 4.925g of tetrabutyl titanate and 40ml of ethanol into a 100ml beaker, place the beaker on a magnetic stirrer, add 50ml of deionized water, and stir for 4 hours to obtain a uniformly mixed white emulsion.

[0030] Step S2: Transfer the emulsion obtained in step S1 to a hydrothermal reaction kettle, place the reaction kettle in a blast drying oven at 150°C for 48 hours, and cool the emulsion in the thermal reaction kettle to room temperature naturally Washing with absolute ethanol to neutrality under the condition of suction filtration to obtain a lithium titanate negative electrode material precursor.

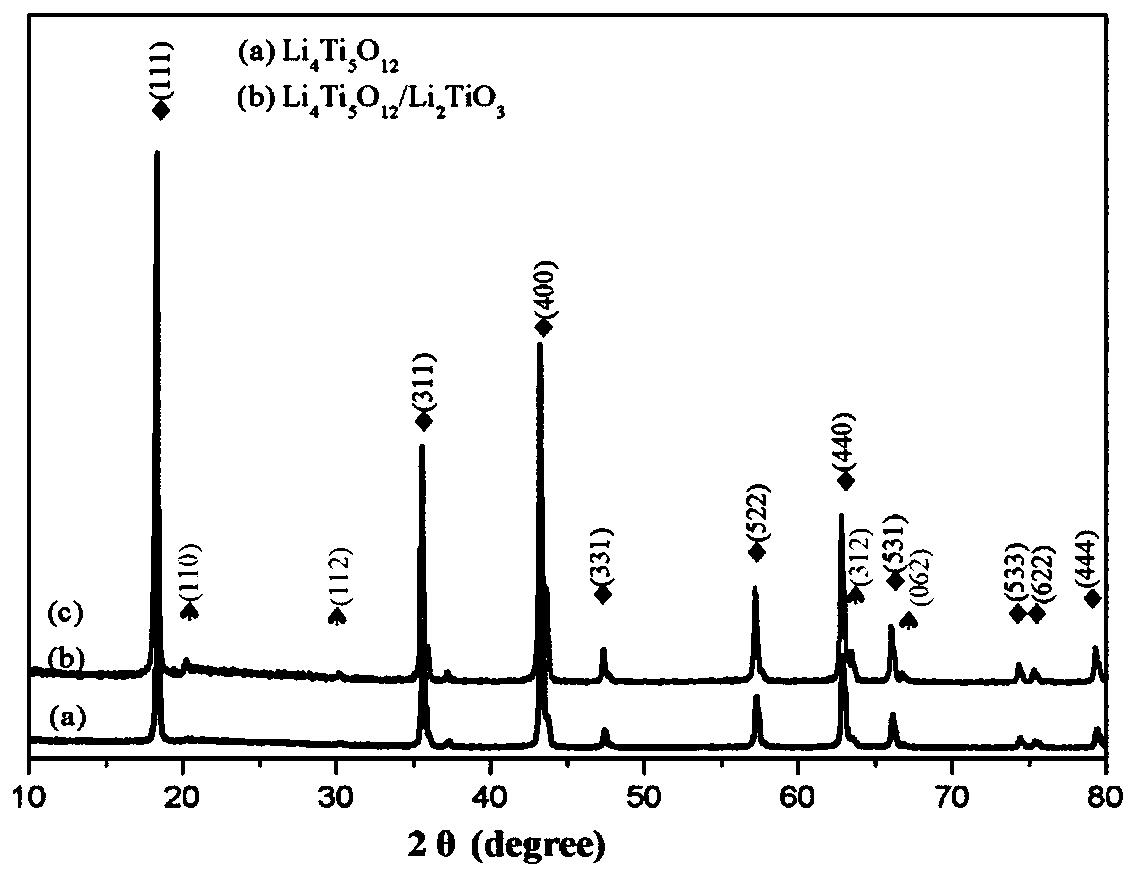

[0031] Step S3: Dry the lithium titanate negative electrode material precursor obtained in step S2 in a blast drying oven at 70°C, and then grind to obtain a composite phase Li 4 Ti 5 o 12 / Li 2 TiO ...

Embodiment 2

[0033] Step S1: Add 0.07gLiOH·H 2 O. Pour 4.92g of tetrabutyl titanate and 40ml of ethanol into a 100ml beaker, place the beaker on a magnetic stirrer, add 50ml of deionized water, and stir for 4 hours to obtain a uniformly mixed white emulsion.

[0034] Step S2: Transfer the emulsion obtained in step S1 to a hydrothermal reaction kettle, place the reaction kettle in a blast drying oven at 150°C for 40 hours, and cool the emulsion in the thermal reaction kettle to room temperature naturally Washing with absolute ethanol to neutrality under the condition of suction filtration to obtain a lithium titanate negative electrode material precursor.

[0035] Step S3: Dry the lithium titanate negative electrode material precursor obtained in step S2 in a blast drying oven at 70°C, and then grind to obtain a composite phase Li 4 Ti 5 o 12 / Li 2 TiO 3 anode material, where Li 2 TiO 3 in Li 4 Ti 5 o 12 / Li 2 TiO 3 The proportion of negative electrode material is 2%.

Embodiment 3

[0037] Step S1: Add 0.08gLiOH·H 2 O. Pour 4.93g of tetrabutyl titanate and 40ml of ethanol into a 100ml beaker, place the beaker on a magnetic stirrer, add 50ml of deionized water, and stir for 4 hours to obtain a uniformly mixed white emulsion.

[0038] Step S2: Transfer the emulsion obtained in step S1 to a hydrothermal reaction kettle, place the reaction kettle in a blast drying oven at 150°C for 48 hours, and cool the emulsion in the thermal reaction kettle to room temperature naturally Washing with absolute ethanol to neutrality under the condition of suction filtration to obtain a lithium titanate negative electrode material precursor.

[0039] Step S3: Dry the lithium titanate negative electrode material precursor obtained in step S2 in a blast drying oven at 70°C, and then grind to obtain a composite phase Li 4 Ti 5 o 12 / Li 2 TiO 3 anode material, where Li 2 TiO 3 in Li 4 Ti 5 o 12 / Li 2 TiO 3 The proportion of negative electrode material is 10%.

[0040]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com