High-performance lithium ion battery composite membrane and preparation method thereof

A composite diaphragm, high-performance technology, applied in the direction of secondary batteries, battery pack components, circuits, etc., can solve the problems of composite membrane lyophobicity not involved, achieve good binding, improve lyophilic performance, and improve performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

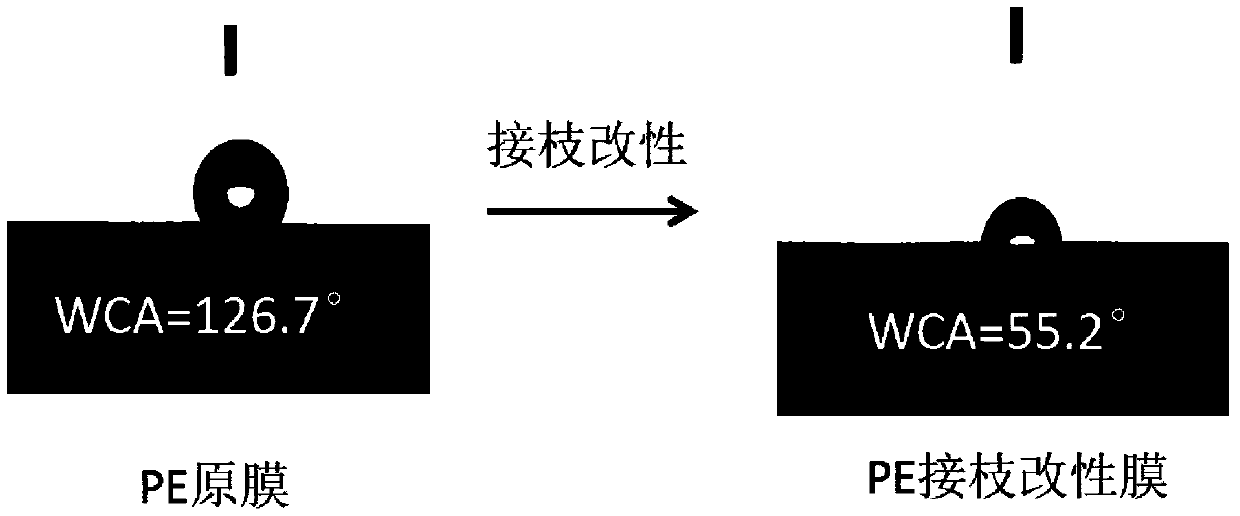

[0022] 1) The fully cleaned and dried PE diaphragm is corona treated at a power of 500W for 120s, and then the corona-treated PE microporous membrane is placed in a dichloromethane solution with a mass concentration of 5.0wt% methyl methacrylate In the process, the grafting reaction was carried out at 50°C for 150 minutes, then the PE film was taken out, washed with deionized water, and fully dried in a vacuum oven;

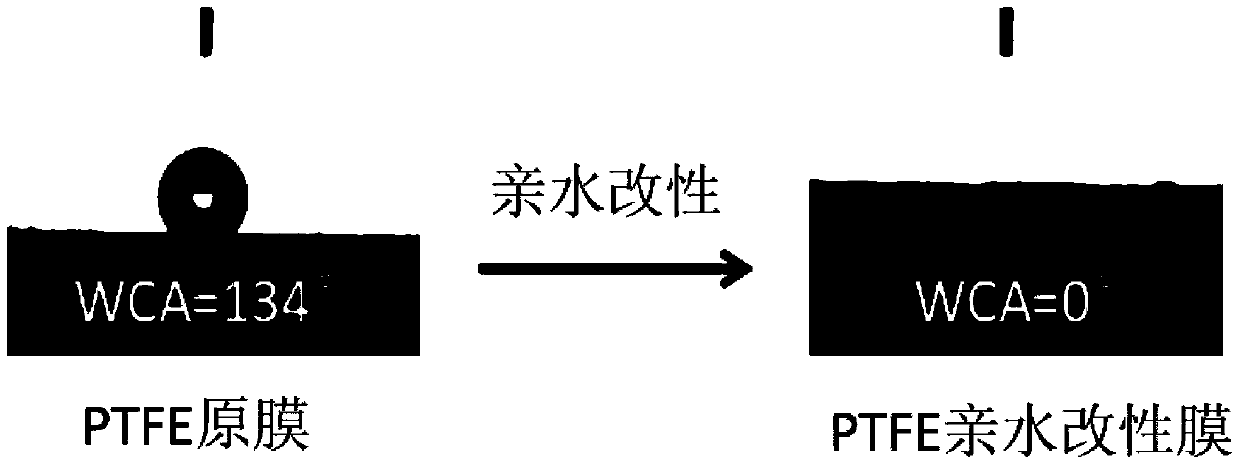

[0023] 2) Immerse the cleaned and fully dried PTFE diaphragm in 0.05 wt% N-[3-(p-perfluorononenyloxybenzamido)propyl]-N,N,N-tri In the methyl ammonium iodide solution, take it out after 120min, wash it with deionized water, and dry it in vacuum;

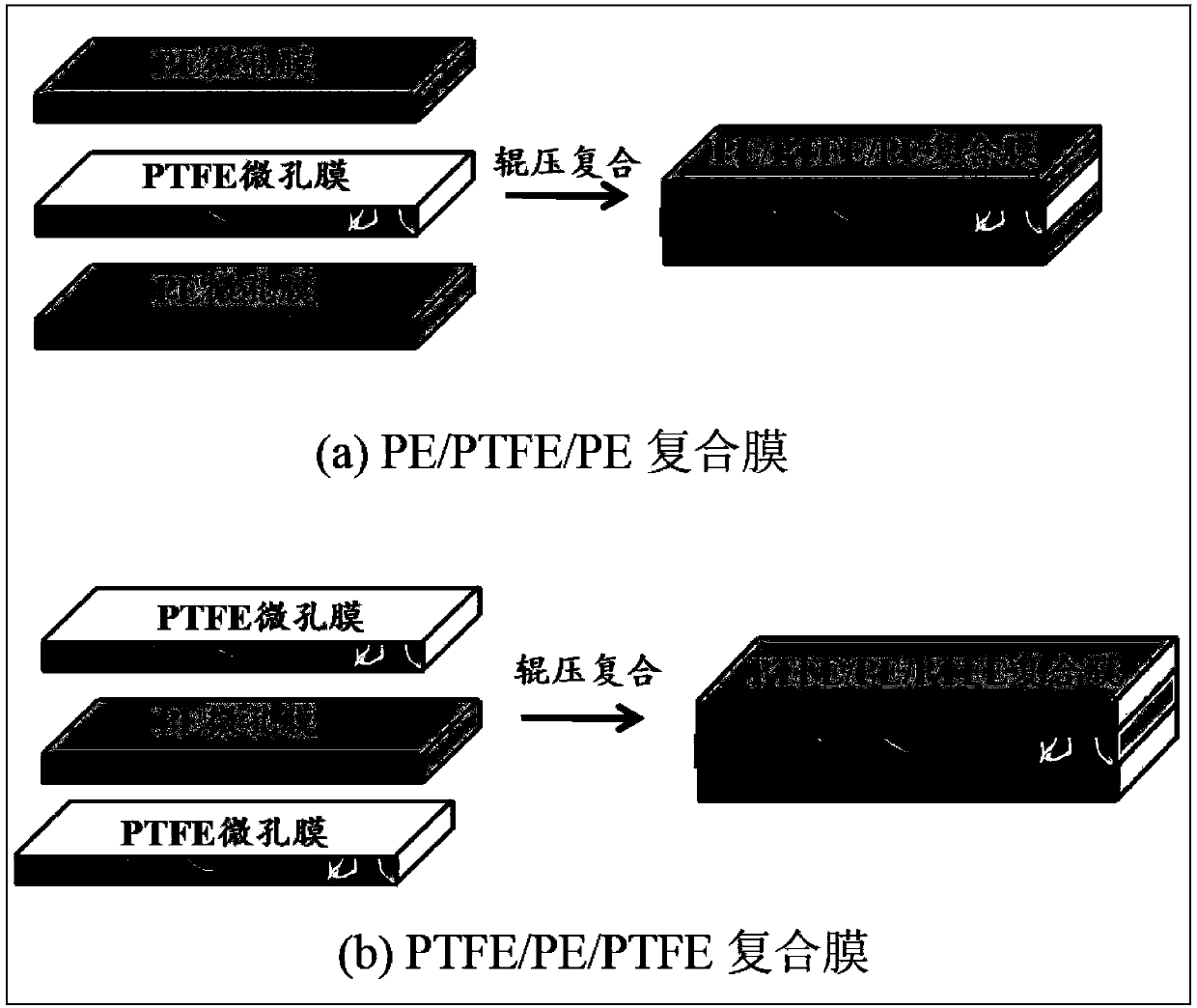

[0024] 3) Modified PTFE microporous membrane and PE microporous membrane composite

[0025] The PE diaphragm modified in step (1) and the PTFE diaphragm modified in step (2) are respectively laminated by PE / PTFE / PE in a laminated manner. The composite temperature is 80°C and the pressure is 0.1MPa. The speed is 0.1m / m...

Embodiment 2

[0027] 1) The fully cleaned and dried PE diaphragm was corona-treated at a power of 1800W for 10s, and then the corona-treated PE microporous membrane was placed in a dichloromethane solution with a mass concentration of 1.0wt% methyl methacrylate In the process, the grafting reaction was carried out at 110°C for 45 minutes, and then the PE film was taken out, washed with deionized water, and fully dried in a vacuum oven;

[0028] 2) Immerse the cleaned and fully dried PTFE diaphragm into N-[3-(p-perfluorononenyloxybenzamido)propyl]-N,N,N-tri In the methyl ammonium iodide solution, take it out after 10min, wash it with deionized water, and dry it in vacuum;

[0029] 3) Modified PTFE microporous membrane and PE microporous membrane composite

[0030] The PE diaphragm modified in step (1) and the PTFE diaphragm modified in step (2) are laminated by PE / PTFE / PE respectively, the composite temperature is 25°C, the pressure is 20MPa, and the speed of the composite roller is It is ...

Embodiment 3

[0032] 1) The fully cleaned and dried PE diaphragm was corona-treated at a power of 1000W for 80s, and then the corona-treated PE microporous membrane was placed in a dichloromethane solution with a mass concentration of 2.0wt% methyl methacrylate In the process, the grafting reaction was carried out at 85°C for 100 minutes, then the PE film was taken out, washed with deionized water, and fully dried in a vacuum oven;

[0033] 2) Immerse the cleaned and fully dried PTFE diaphragm into N-[3-(p-perfluorononenyloxybenzamido)propyl]-N,N,N-tri In the methyl ammonium iodide solution, take it out after 30min, wash it with deionized water, and dry it in vacuum;

[0034] 3) Modified PTFE microporous membrane and PE microporous membrane composite

[0035] The PE diaphragm modified in step (1) and the PTFE diaphragm modified in step (2) are laminated by PE / PTFE / PE respectively, the composite temperature is 65°C, and the pressure is 5.0MPa. The rotational speed is 1.0 m / min. After roll...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com