Room temperature ammonia gas sensor using p-type delafossite structure oxide as sensitive material, and preparation method thereof

An ammonia gas sensor and sensitive material technology, applied in the field of sensitive materials and sensors, can solve the problems of poor selectivity, long response-recovery time, etc., and achieve the effects of convenient operation, short response and recovery time, and avoiding the aging or damage of the overall device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

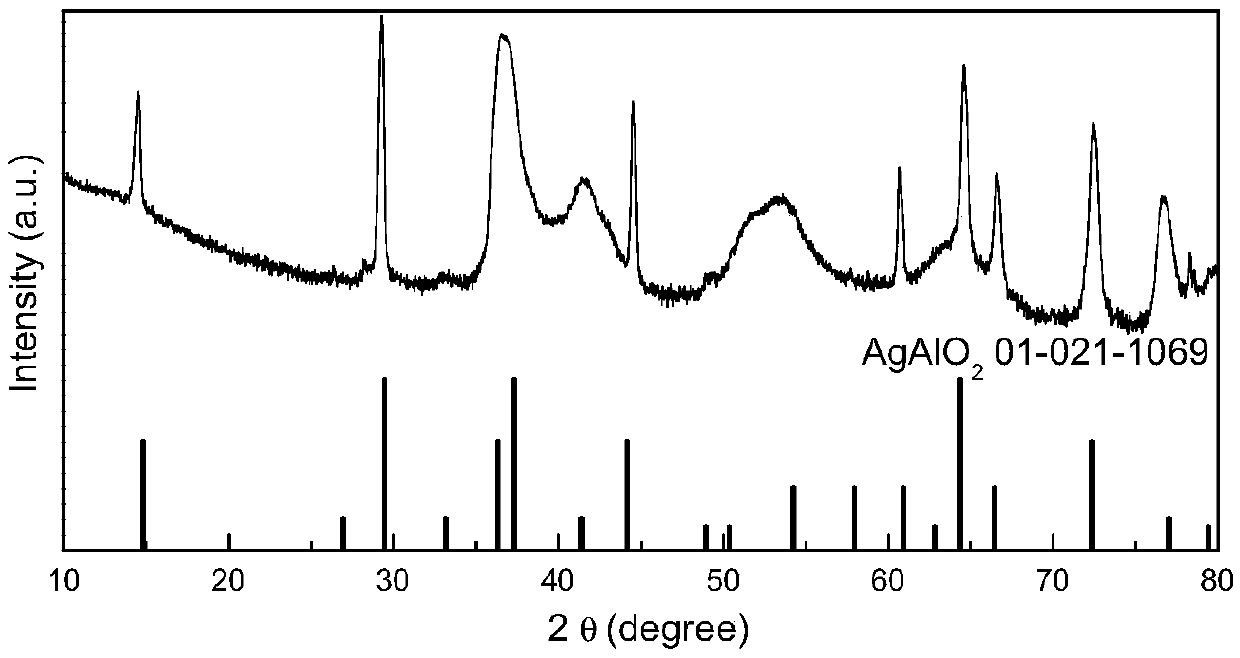

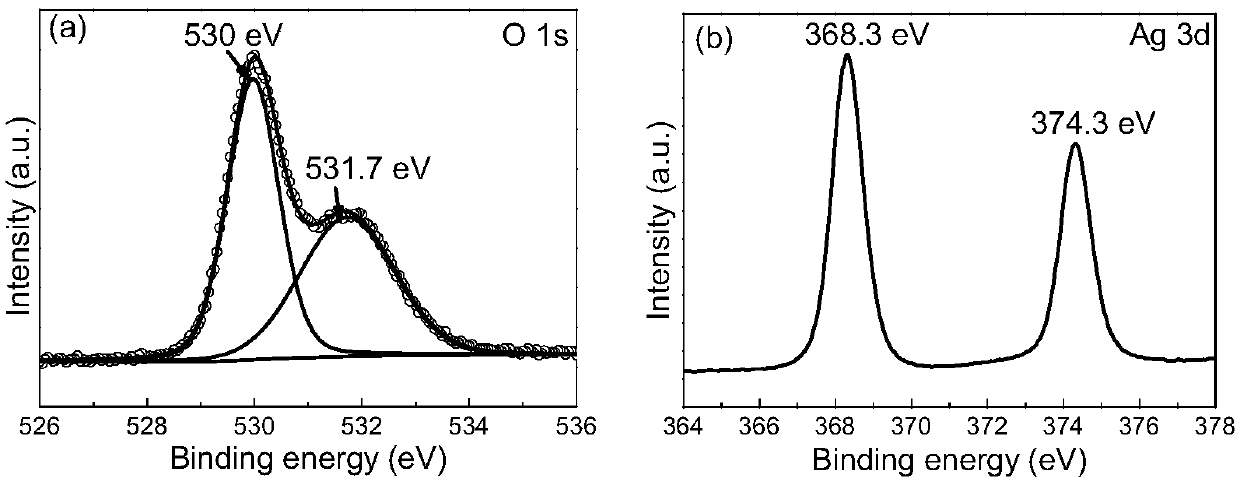

[0031] A room temperature ammonia sensor using p-type delafossite structure oxide as a sensitive material, including a gas-sensing material and a substrate, the gas-sensing material is evenly coated on the surface of the substrate, the coating thickness of the gas-sensing material is 10 μm, and the gas-sensing material is p-type delafossite structure AgAlO 2 Nanoparticles, particle diameter is 200nm-500nm;

[0032] Its preparation method comprises the following steps:

[0033] Step 1: Preparation of p-type delafossite structure AgAlO 2 Nanoparticles: 0.015mol Al(NO 3 ) 3 9H 2 O and 0.015molAgNO 3 Dissolve in 70 ml deionized water, add 2.4 g NaOH after dissolving, pour the above solution into 100 ml polytetrafluoroethylene lining, put the autoclave in an oven at 210 ° C for 64 hours, cool to room temperature and take it out, silver white The powder is washed with 1M / L dilute ammonia water, 1M / L dilute nitric acid, deionized water, and dried for use;

[0034] Step 2, prep...

Embodiment 2

[0038] A room temperature ammonia sensor using p-type delafossite structure oxide as the sensitive material, including a gas-sensing material and a substrate, the gas-sensing material is evenly coated on the surface of the substrate, the coating thickness of the gas-sensing material is 50 μm, and the gas-sensing material is p-type delafossite structure AgAlO 2 Nanoparticles, the particle diameter is 1μm-3μm;

[0039] Its preparation method comprises the following steps:

[0040] Step 1: Preparation of p-type delafossite structure AgAlO 2 Nanoparticles: 0.015mol Al(NO 3 ) 3 9H 2 O and 0.01575mol AgNO 3 Dissolve in 70 ml deionized water, add 3 g NaOH after dissolving, pour the above solution into 100 ml polytetrafluoroethylene lining, put the autoclave in an oven at 220 ° C for 64 hours, cool to room temperature and take it out, silver white The powder is washed with 1M / L dilute ammonia water, 1M / L dilute nitric acid, deionized water, and dried for use;

[0041] Step 2, p...

Embodiment 3

[0044] A room temperature ammonia sensor using p-type delafossite structure oxide as a sensitive material, including a gas-sensing material and a substrate, the gas-sensing material is evenly coated on the surface of the substrate, the coating thickness of the gas-sensing material is 100 μm, and the gas-sensing material is p-type delafossite structure AgAlO 2 Nanoparticles, the particle diameter range is 200nm-500nm;

[0045] Its preparation method comprises the following steps:

[0046] Step 1: Preparation of p-type delafossite structure AgAlO 2 Nanoparticles: 0.015mol Al(NO 3 ) 3 9H 2 O and 0.015molAgNO 3 Dissolve in 70 ml deionized water, add 2.4 g NaOH after dissolving, pour the above solution into 100 ml polytetrafluoroethylene lining, put the autoclave in an oven at 220 ° C for 64 hours, cool to room temperature and take it out, silver white The powder is washed with 1M / L dilute ammonia water, 1M / L dilute nitric acid, deionized water, and dried for use;

[0047] S...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com