Method of improving mechanical property of material by changing metal material gradient nano twin-crystal structure

A technology of metal materials and nano-twins, which is applied in nanotechnology, optics, electrolytic processes, etc., can solve the problem that metal materials are difficult to have both high strength and good plasticity, and achieve high strength, increased yield strength, and high room temperature stretching The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Gradient nano-twin structure copper material, the total thickness of the sample is 400 μm. The sample is composed of micron-sized columnar grains growing along the deposition direction. The grains contain high-density twin boundaries, and most of the twin boundaries are parallel to the growth surface. The pure copper material in this embodiment has a gradient layer, and the grain size and the thickness of the twinned lamellar layer in the material show a monotonically increasing gradient along the thickness direction, with the average grain size gradually transitioning from 2.5 μm to 15.8 μm, and the average twin The wafer layer thickness gradually transitions from 29nm to 72nm, such as figure 1 shown.

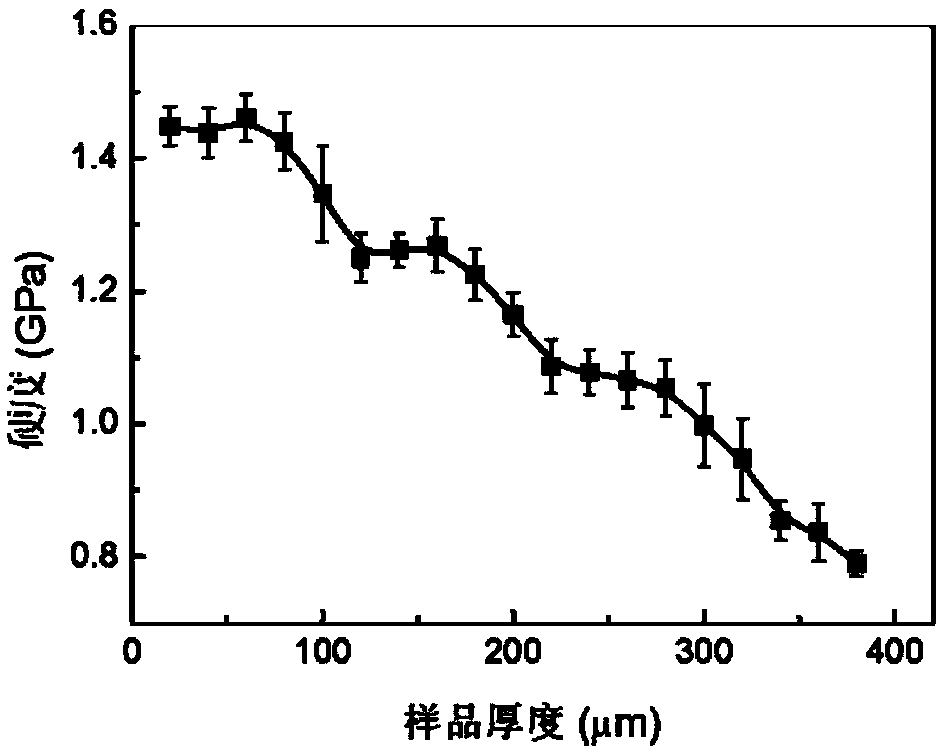

[0045] In this embodiment, the microhardness of the gradient nano-twinned copper material gradually decreases along the thickness direction, from 1.5 GPa to 0.8 GPa, showing a gradient distribution, with a structural gradient of 1.75 GPa / mm, such as figure 2 shown. ...

Embodiment 2

[0048] The difference from Example 1 is:

[0049] The gradient nano-twinned copper material has 2 gradient layers. Along the thickness direction, the grain size and the thickness of the twinned lamellar layers of the material present a symmetrical gradient change that first increases and then decreases, as shown in Figure 4 shown.

[0050] In this example, the cross-sectional hardness of the gradient nano-twinned copper material first decreases and then increases along the thickness direction, and the structural gradient is 3.2 GPa / mm, as Figure 5 shown.

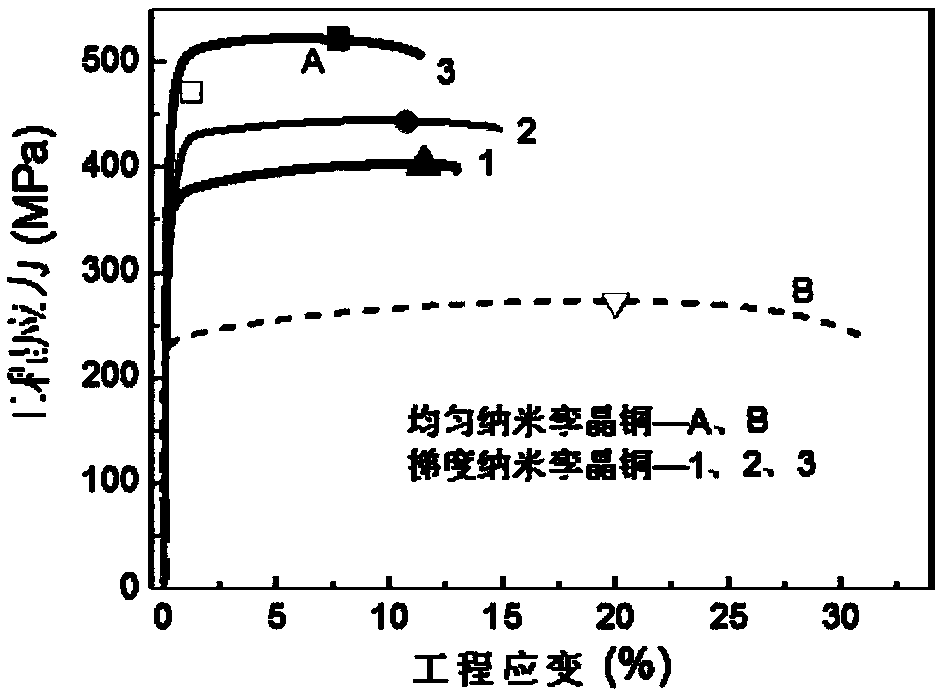

[0051] In this embodiment, the room temperature stretching of the gradient nano-twin structure copper material: when the stretching rate is 5×10 -3 the s -1 , the yield strength is 437±19MPa, the tensile strength is 471±18MPa, the uniform elongation is 9.2±1%, and the elongation at break is 14±1.9%, such as Figure 4 Shown in curve 2.

Embodiment 3

[0053] The difference from Example 1 is:

[0054] The gradient nano-twin structure copper material has 8 gradient layers. Along the thickness direction, the grain size and the thickness of the twinned lamellar layer of the material show a four-period gradient change that first increases and then decreases, and its microstructure is shown in Figure 6 shown.

[0055] In this embodiment, the hardness of the gradient nano-twinned structure copper material presents a four-period gradient change along the thickness direction, which first decreases and then increases, and the structural gradient is 11.6GPa / mm, such as Figure 7 shown.

[0056] In this embodiment, the room temperature stretching of the gradient nano-twinned copper material: when the stretching rate is 5×10 -3 the s -1 , the yield strength is 481±15MPa, the tensile strength is 520±12MPa, the uniform elongation is 7±0.5%, and the elongation at break is 11.7±1.3%. Such as Figure 4 Shown in curve 3.

[0057] It c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Stretching rate | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com