Water-based self-crosslinking cation copolymer emulsion as well as preparation method and application thereof

A cationic copolymer and self-crosslinking technology, which is applied in the field of coatings, can solve the problems of short antibacterial and antibacterial effects, and achieve the effects of improving water resistance and scrub resistance, reducing collisions, and inhibiting growth and reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

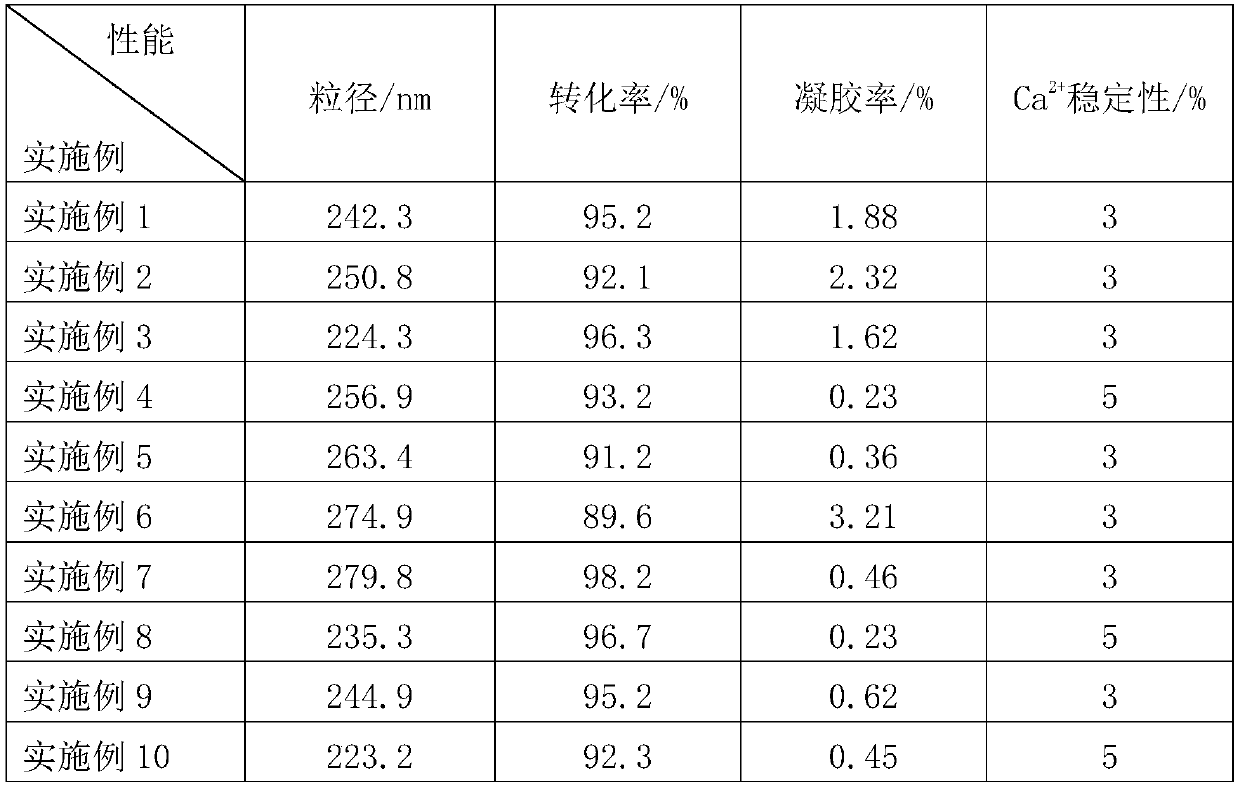

Examples

Embodiment 1

[0031] Using the polymerization process combining seed emulsion method and semi-continuous pre-emulsification method, under nitrogen atmosphere, 30g deionized water, 0.05g cationic emulsifier cetyltrimethylammonium bromide, 0.15g nonionic emulsifier PE6100, 0.05g of pH buffer, 0.1g of methacryloxyethyl dimethyl butyl ammonium bromide, 0.1g of vinyltriethoxysilane, 1.8g of methyl methacrylate, 3.2g of butyl acrylate were added Into the reaction kettle, start stirring for standby;

[0032] Add the remaining 100g of deionized water, 3.2g of emulsifier, 0.25g of pH buffer, 5g of cationic monomer, 4.2g of self-crosslinking monomer, and acrylate monomer into the emulsification kettle, start stirring, emulsify for 0.5h, and set aside ;

[0033] The temperature of the reactor was raised to 80°C, and 0.075 g of azobisisobutylamidine hydrochloride was added to initiate polymerization. After 30 minutes of reaction, the emulsion turned blue. At the same time, drop the emulsion in the em...

Embodiment 2

[0035] Using the polymerization process combining seed emulsion method and semi-continuous pre-emulsification method, under nitrogen atmosphere, 50g deionized water, 0.1g cationic emulsifier cetyltrimethylammonium bromide, 0.1g nonionic emulsifier PE6100, 0.1g of pH buffer, 0.3g of methacryloxyethyl dimethyl butyl ammonium bromide, 0.2g of vinyltriethoxysilane, 2.2g of methyl methacrylate, 2.8g of butyl acrylate were added Into the reaction kettle, start stirring for standby;

[0036] Add the remaining 100g of deionized water, 3.5g of emulsifier, 0.3g of pH buffer, 8g of cationic monomer, 4g of self-crosslinking monomer, and acrylate monomer into the emulsification kettle, start stirring, emulsify for 0.75h, and set aside;

[0037] The temperature of the reactor was raised to 60°C, and 0.15 g of azobisisobutylamidine hydrochloride was added to initiate polymerization. After 30 minutes of reaction, the emulsion turned blue. At the same time, dropwise add the emulsion in the em...

Embodiment 3

[0039] Using the polymerization process combining seed emulsion method and semi-continuous pre-emulsification method, under nitrogen atmosphere, 72g deionized water, 0.15g cationic emulsifier dodecyltrimethylammonium bromide, 0.05g nonionic emulsifier PE6100, 0.1g of pH buffer, 0.5g of methacryloyloxyethyl dimethyl butyl ammonium bromide, 0.3g of vinyltriethoxysilane, 3.3g of methyl methacrylate, and 1.7g of butyl acrylate were added Into the reaction kettle, start stirring for standby;

[0040] Add the remaining 80g of deionized water, 2.8g of emulsifier, 0.3g of pH buffer, 9g of cationic monomer, 2g of self-crosslinking monomer, and acrylate monomer into the emulsification kettle, start stirring, emulsify for 1 hour, and set aside.

[0041] The temperature of the reactor was raised to 75°C, and 0.3 g of azobisisobutylamidine hydrochloride was added to initiate polymerization. After 30 minutes of reaction, the emulsion turned blue. Add dropwise the emulsion in the emulsifica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| water resistance | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com