Welding-free tooth one-time forming method for combination teeth of idle wheel with teeth

A forming method and a tooth-combining technology are applied in the direction of wheels, vehicle parts, metal processing equipment, etc., which can solve the problems of low mechanical properties of parts, high manufacturing costs, and low processing efficiency, so as to improve the mechanical properties of products, reduce processing procedures, The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Embodiment: The one-time forming method of the toothed idler combined with the tooth without welding, the steps are as follows:

[0027] a. Select the raw material bar, grind the surface of the bar, and cut it into a length that meets the requirements after flaw detection for blanking;

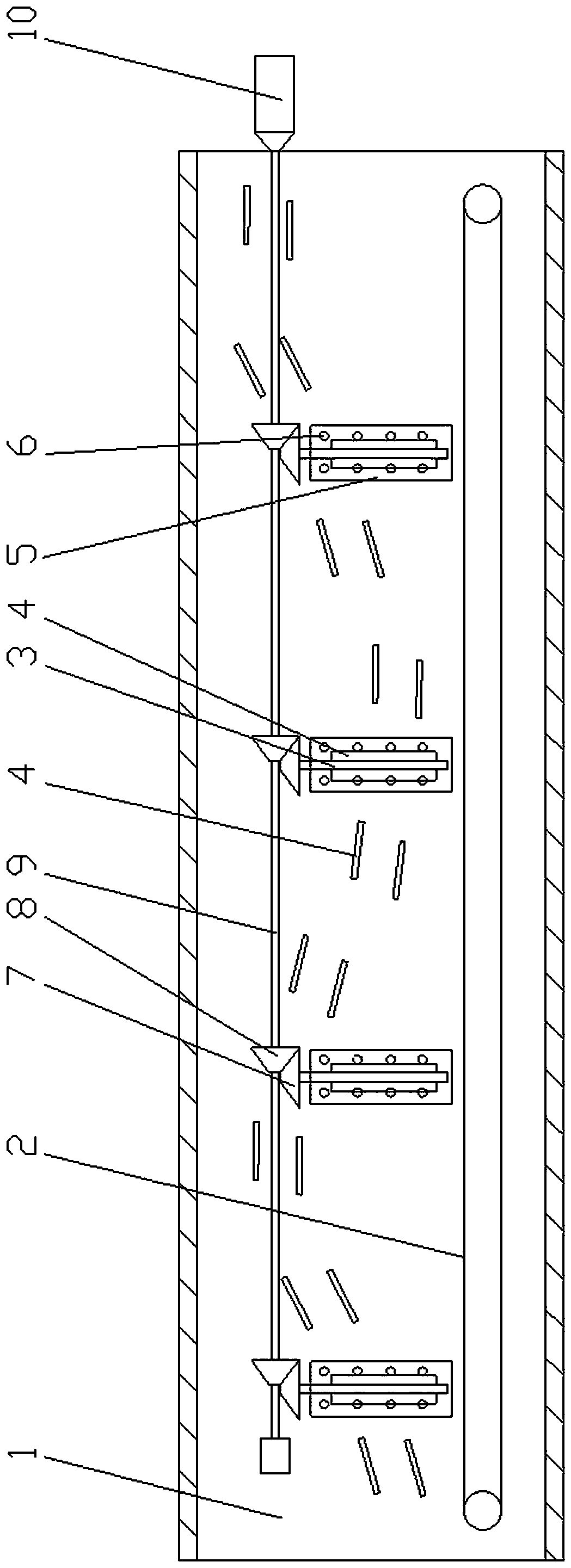

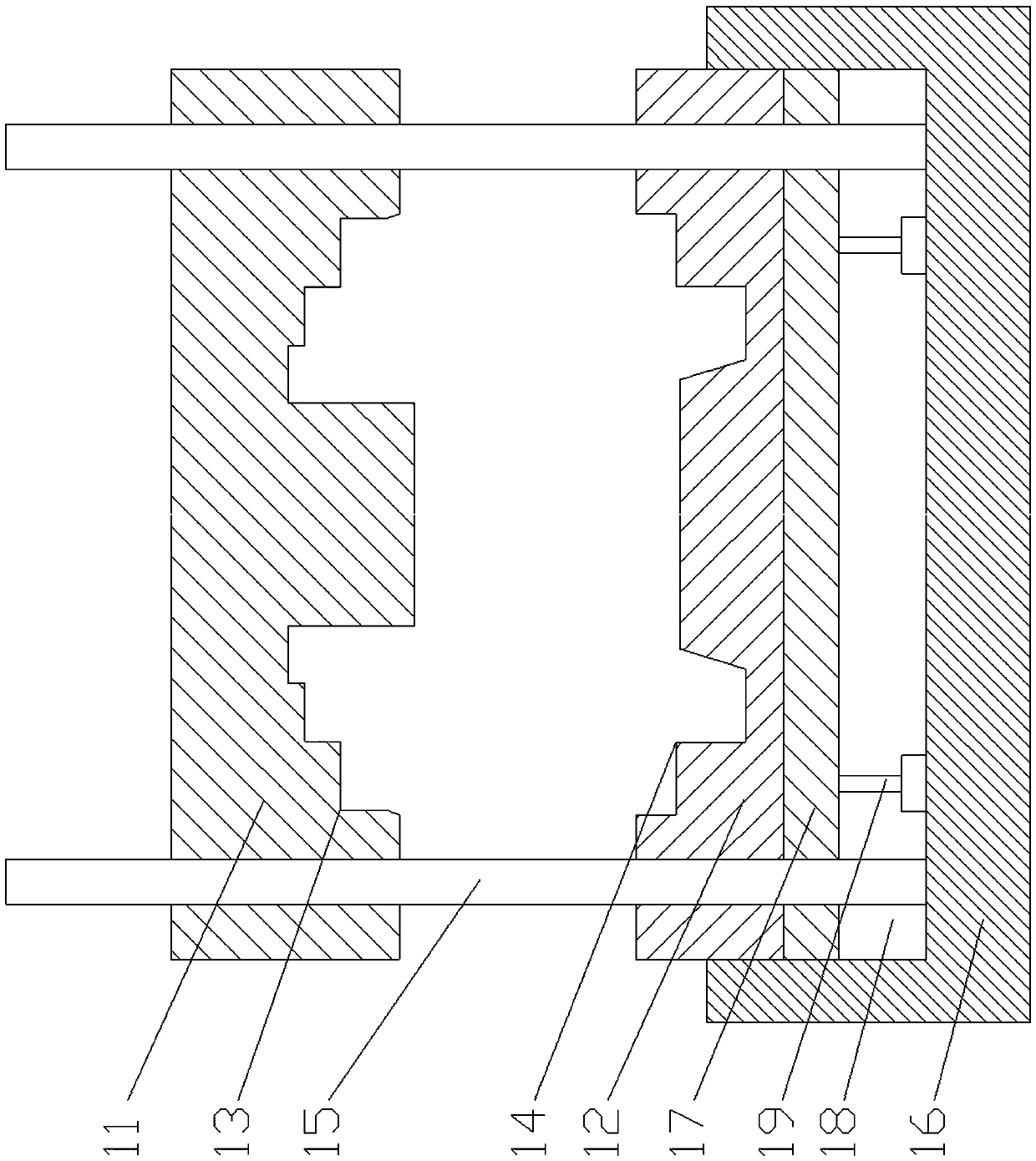

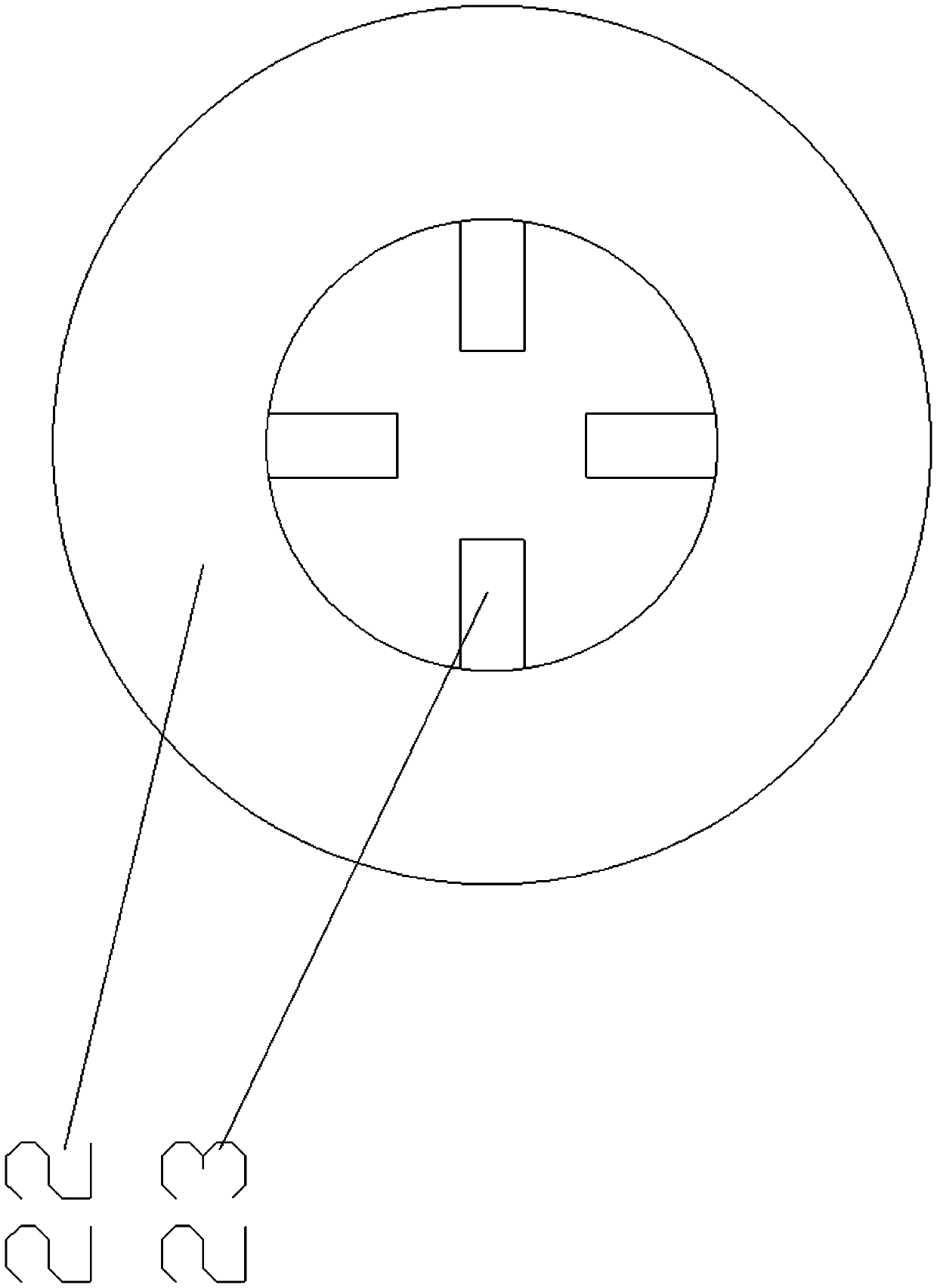

[0028] b. Heating the rod to 850°C in the heating device with intermediate frequency, such as figure 1 , the heating device includes a heating channel 1, the bottom of the heating channel is provided with a heating conveyor chain 2, the upper part of the heating channel is connected with a number of rotating shafts 3, and the rotating shafts are connected with a number of electric heating tubes 4 arranged vertically, and the outside of the electric heating tube is provided with The casing 5 has a through hole 6 on the casing, the first bevel gear 7 is connected to the rotating shaft 3, the first bevel gear is meshed with the second bevel gear 8, and all the second bevel gears are connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com