Oil injector bush

A fuel injector and bushing technology, which is applied to machines/engines, fuel injection devices, engine components, etc., can solve problems such as low heat transfer coefficient, stuck needle valve, and inability to set water chambers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

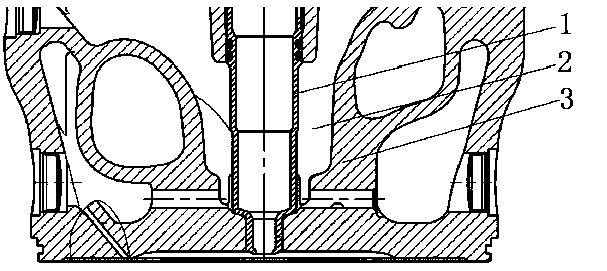

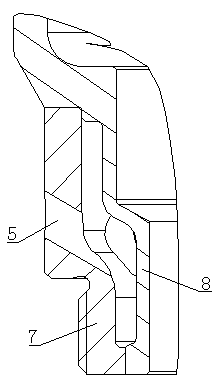

[0023] Such as Figure 2 to Figure 7 As shown, the fuel injector bushing includes a bushing body that can be fitted on the fuel injector to be cooled and the fuel injection nozzle to be cooled, and a cooling water chamber is formed between the bushing body and the cylinder head to be installed. The bushing body includes an upper bushing 9 corresponding to the injector to be cooled and a lower bushing 8 corresponding to the nozzle to be cooled. The upper bushing 9 and the lower bushing 8 are integrally cast, and the thickness of the lower bushing 8 is Less than the thickness of the upper bush 9, the minimum thickness of the lower bush 8 in the present invention can reach 2mm; In the inner water chamber of the oil nozzle, the outer bushing 7 is provided with an inlet 5 and an outlet 6 communicating with the cooling water chamber, and the inlet 5 is arranged downwardly from the outside to the inside, so that the cooling water flows into the inner water chamber. There are a plura...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com