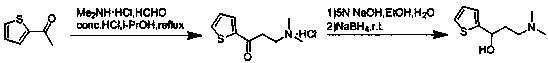

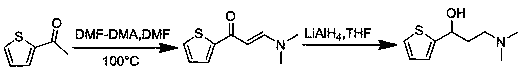

Synthesis method of key intermediate for preparing duloxetine hydrochloride from 2-acetylthiophene

A technology of duloxetine hydrochloride and acetylthiophene, which is applied in the field of synthesis of key intermediates of duloxetine hydrochloride prepared from 2-acetylthiophene, can solve problems such as volatile, expensive and unstable DMF-DMA raw materials, and achieve The effect of short reaction cycle, avoiding the use of expensive catalysts, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: Preparation of (dimethylamino)-1-(2-thienyl)-2-propene-1-one

[0031] Preparation of sodium methoxide / methanol solution: Dissolve 2.7g (50mmol) of sodium methoxide in 10mL of methanol and dissolve evenly to obtain sodium methoxide / methanol solution;

[0032] Add 18.45g (100mmol) of cyanuric chloride, 9.5mL of 1,4-dioxane, and 7.31g (100mmol) of N,N-dimethylformamide into a 250mL three-necked flask and mix well to obtain a mixed solution; solution and 12.60g (100mmol) of 2-acetylthiophene, added to the sodium methoxide / methanol solution, stirred and mixed, the temperature of the reaction solution was controlled to 20°C for the reaction, followed by TLC (petroleum ether: ethyl acetate = 2:1), the reaction ended Afterwards, the solvent was distilled off under reduced pressure, and crystals were precipitated. The crystals were recrystallized in a mixed solvent of dichloromethane:petroleum ether (V:V=1:3), and 14.12g of a light yellow solid was obtained after s...

Embodiment 2

[0034] Preparation of 3-(dimethylamino)-1-(2-thienyl)-2-propen-1-one:

[0035] Preparation of sodium methoxide / methanol solution: Dissolve 10.8g (200mmol) of sodium methoxide in 33mL of methanol and dissolve evenly to obtain sodium methoxide / methanol solution;

[0036] Add 55.35g (300mmol) of cyanuric chloride, 148mL of 1,4-dioxane, and 36.54g (500mmol) of N,N-dimethylformamide into a 250mL three-necked bottle and mix well to obtain a mixed solution; and 12.60 g (100 mmol) of 2-acetylthiophene, added to the sodium methoxide / methanol solution, stirred and mixed, controlled the temperature of the reaction solution to 40°C for the reaction, followed by TLC (petroleum ether: ethyl acetate = 2:1), after the reaction , the solvent was distilled off under reduced pressure, and crystals were precipitated. The crystals were recrystallized in a mixed solvent of dichloromethane:petroleum ether (V:V=1:3), and after suction filtration and drying, 15.31g of a light yellow solid was obtained...

Embodiment 3

[0038] Preparation of 3-(dimethylamino)-1-(2-thienyl)-2-propen-1-one:

[0039] Preparation of sodium methoxide / methanol solution: Dissolve 5.4g (100mmol) of sodium methoxide in 22mL of methanol and dissolve evenly to obtain sodium methoxide / methanol solution;

[0040] Add 7.38g (40mmol) of cyanuric chloride, 73mL of 1,4-dioxane, and 58.5g (800mmol) of N,N-dimethylformamide into a 250mL three-necked bottle and mix well to obtain a mixed solution; Add 12.60 g (100 mmol) of 2-acetylthiophene to sodium methoxide / methanol solution, stir and mix, control the temperature of the reaction solution to 50°C for reaction, TLC tracking (petroleum ether: ethyl acetate = 2:1), after the reaction , the solvent was distilled off under reduced pressure, and crystals were precipitated. The crystals were recrystallized in a mixed solvent of dichloromethane:petroleum ether (V:V=1:3), and 16.51g of a light yellow solid was obtained after suction filtration and drying, which was 3-(di Methylamino)-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com