Arc discharge processing purging area regulating system

A technology of arc discharge and control system, which is applied in the direction of electric processing equipment, metal processing equipment, circuits, etc., can solve the problems of poor cooling effect in the processing area of erosion products, poor application, low flow rate of working fluid, etc., and achieve improvement The surface quality of the workpiece, the cooling effect is good, and the effect of improving the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

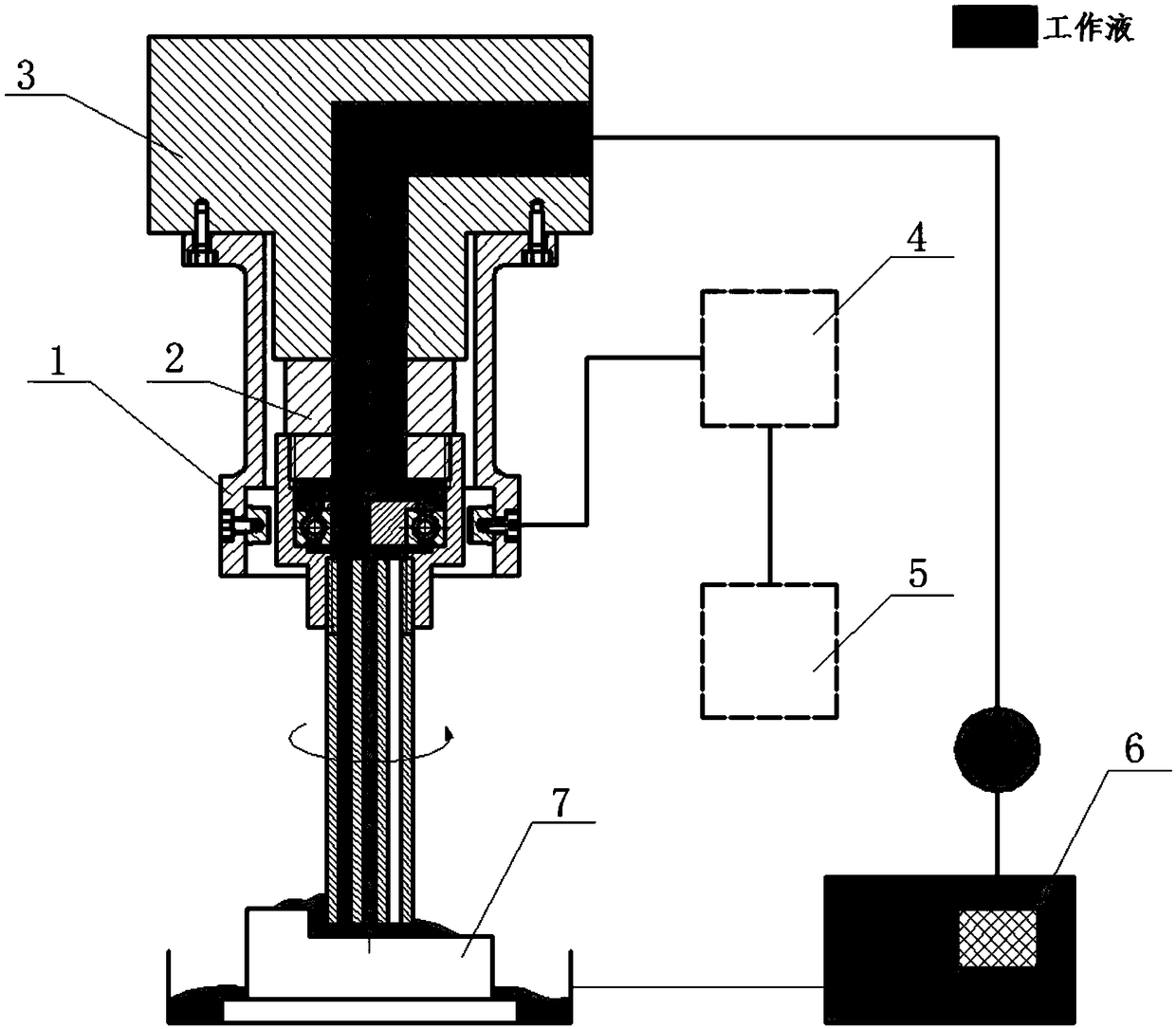

Method used

Image

Examples

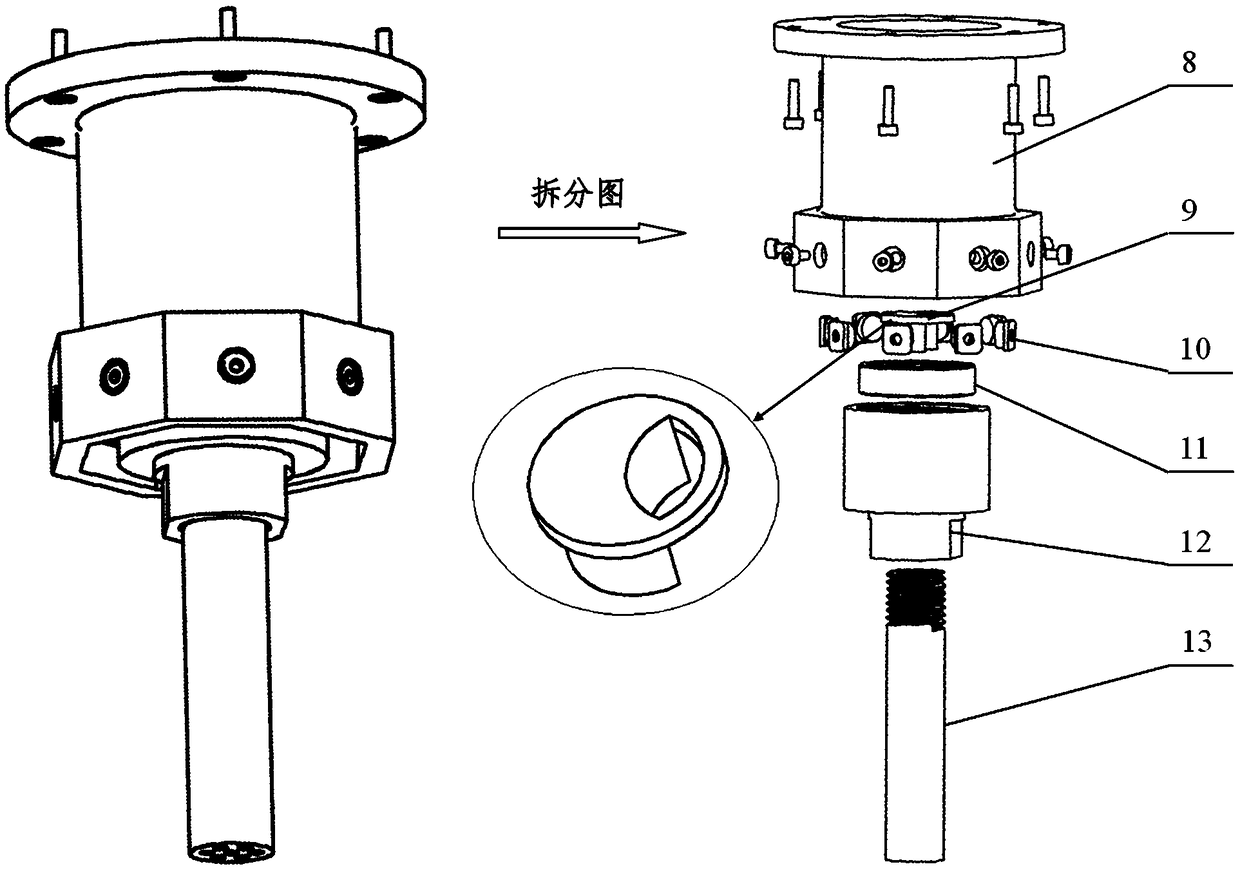

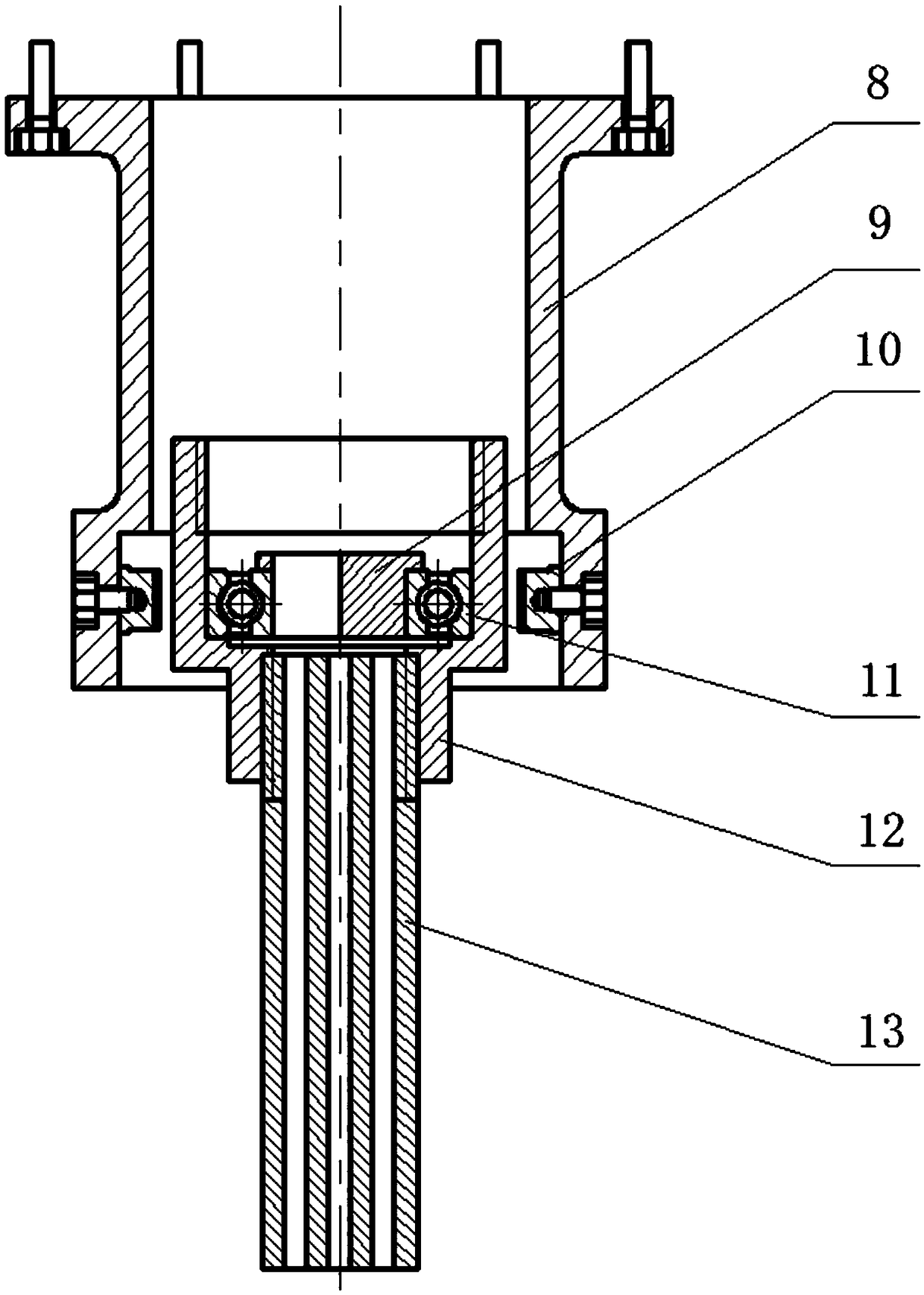

Embodiment 1

[0038] On the electromagnet installation base, 8 miniature disc-shaped electromagnets are evenly arranged. The diameter of the electromagnet is 20mm, the height is 15mm, and the suction force is 25N. It is installed and fixed through the M4 threaded hole. The material of the electrode adapter in the controllable electrode device in the flushing area is brass, the material of the bearing is ceramic, the material of the control ring is martensitic stainless steel, the electrode is a porous internal flushing graphite electrode with a diameter of 20mm, and the material of the workpiece is nickel-based superalloy , and complete the installation and connection of all components of the system as required. When performing high-speed arc discharge milling, connect the electrode and the workpiece to the two poles of the discharge power supply. The parameters of the power supply used are: open circuit voltage 90V, peak current 600A, pulse width 8ms and pulse interval 2ms, electrode rotati...

Embodiment 2

[0040] Change the number of electromagnets to 4, keep other conditions constant in embodiment 1, carry out as follows Figure 5 The arc discharge machining of the square trajectory shown, the side length of the square is 100mm, and the groove depth is 3mm. During the machining process, the machining feed direction is Y-axis positive direction, X-axis positive direction, Y-axis negative direction, and X-axis negative direction. By reading the machining track information, the control unit automatically generates 4 solenoid start-stop states. instructions, which can in turn be formed as Figure 5 The 4 different irrigation area positions are shown.

[0041] Experiments have shown that the control unit of the arc discharge machining flushing area control system of the present invention is connected with the machine tool numerical control system through the interface of the machine tool numerical control system and the control unit, reads the machining track, and automatically gen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com