Stable-protein high-internal-phase oil-in-water emulsion and preparation method thereof

A protein solution and protein technology, applied in the field of emulsion preparation, to achieve the effects of good viscoelasticity, broad application space and wide sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] (1) Accurately weigh 1 g of sodium caseinate spray-dried sample, disperse it in 99 g of distilled water (the default density of distilled water is 1.00 g / mL), and stir continuously at room temperature for 2 hours to fully disperse the protein.

[0035] (2) Put the obtained sodium caseinate dispersion at 4°C for 12 hours at low temperature (add sodium azide with a mass concentration of 0.02g / 100g to the protein dispersion before standing to prevent the growth of microorganisms), so that the protein is fully hydrated. to obtain a sodium caseinate stock solution that is 1g / 100g in mass concentration.

[0036] (3) Before preparing the emulsion, stir the sodium caseinate stock solution at room temperature for 0.5 h to bring the temperature back to room temperature and promote the uniform dispersion of the protein.

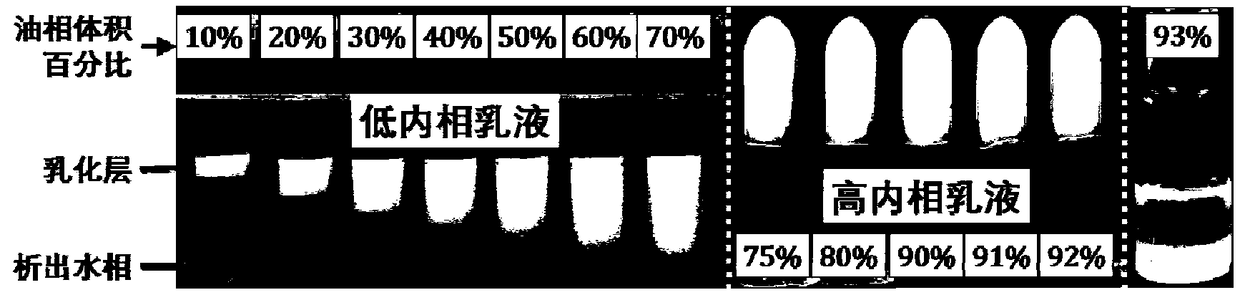

[0037] (4) Take 4.5mL, 4.0mL, 3.5mL, 3.0mL, 2.5mL, 2.0mL, 1.5mL, 1.25mL, 1.0mL, 0.5mL, 0.45mL and 0.4mL of sodium caseinate stock solution in 2.0mL cm vials as ...

Embodiment 2

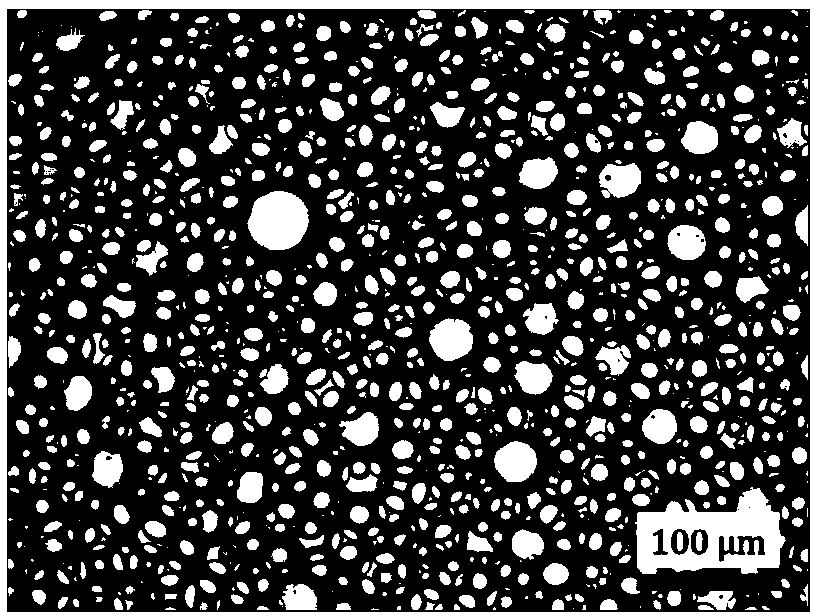

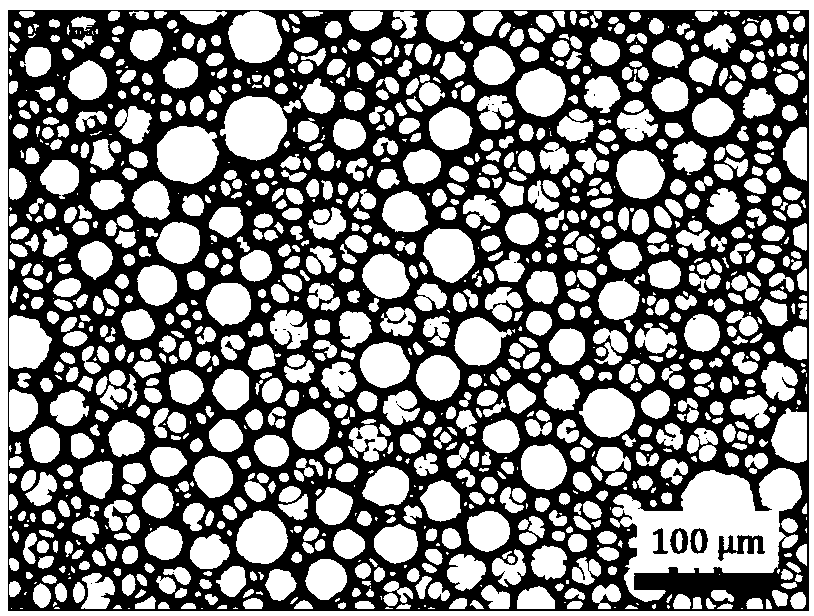

[0044] According to the method of Example 1, a concentrated high internal phase oil-in-water emulsion stable with bovine serum albumin was prepared. The deproteinized sample was replaced by bovine serum albumin freeze-dried samples, the oil phase was replaced by soybean oil, and the emulsification method was replaced by first shear homogenization (shear rate: 5000rpm, shear time: 2min) and then ultrasonic homogenization (ultrasonic power: 285W, Ultrasonic intermittent time is 3s, and ultrasonic treatment total time is 2min), other operation is the same as embodiment 1. The comparison operation was shear homogenization using only the same parameters. After the emulsion is left to stand and the stratification is stable, all the water phase precipitated at the bottom is extracted with a syringe with a needle. The recovery rate of the water phase exceeds 92%, and the remaining emulsified layer is an oil-in-water emulsion with a volume percentage of the oil phase exceeding 75%. Th...

Embodiment 3

[0046] According to the method of Example 1, a concentrated high internal phase oil-in-water emulsion with stable lysozyme was prepared, the protein was removed and replaced with lysozyme freeze-dried sample, the oil phase was replaced with peanut oil, and the emulsification method was replaced with shear homogenization (shear) The cutting rate is 5000rpm, and the shearing time is 2min) and high-pressure micro-jet homogenization (the homogenization pressure is 40MPa, and the number of times of treatment is 1 time), other operations are the same as in Example 1. The comparison operation is the shear homogenization using only the same parameters or the first shear homogenization and then the ultrasonic homogenization according to the method described in Example 2. After the emulsion is left to stand and the stratification is stable, all the water phase precipitated at the bottom is extracted with a syringe with a needle. The recovery rate of the water phase exceeds 92%, and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com