Treatment method for treating industrial wastewater

A technology of industrial wastewater and treatment methods, applied in the field of treatment, can solve the problems of complex treatment process steps and cumbersome treatment, and achieve the effect of compact structure, high treatment efficiency and reduced steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

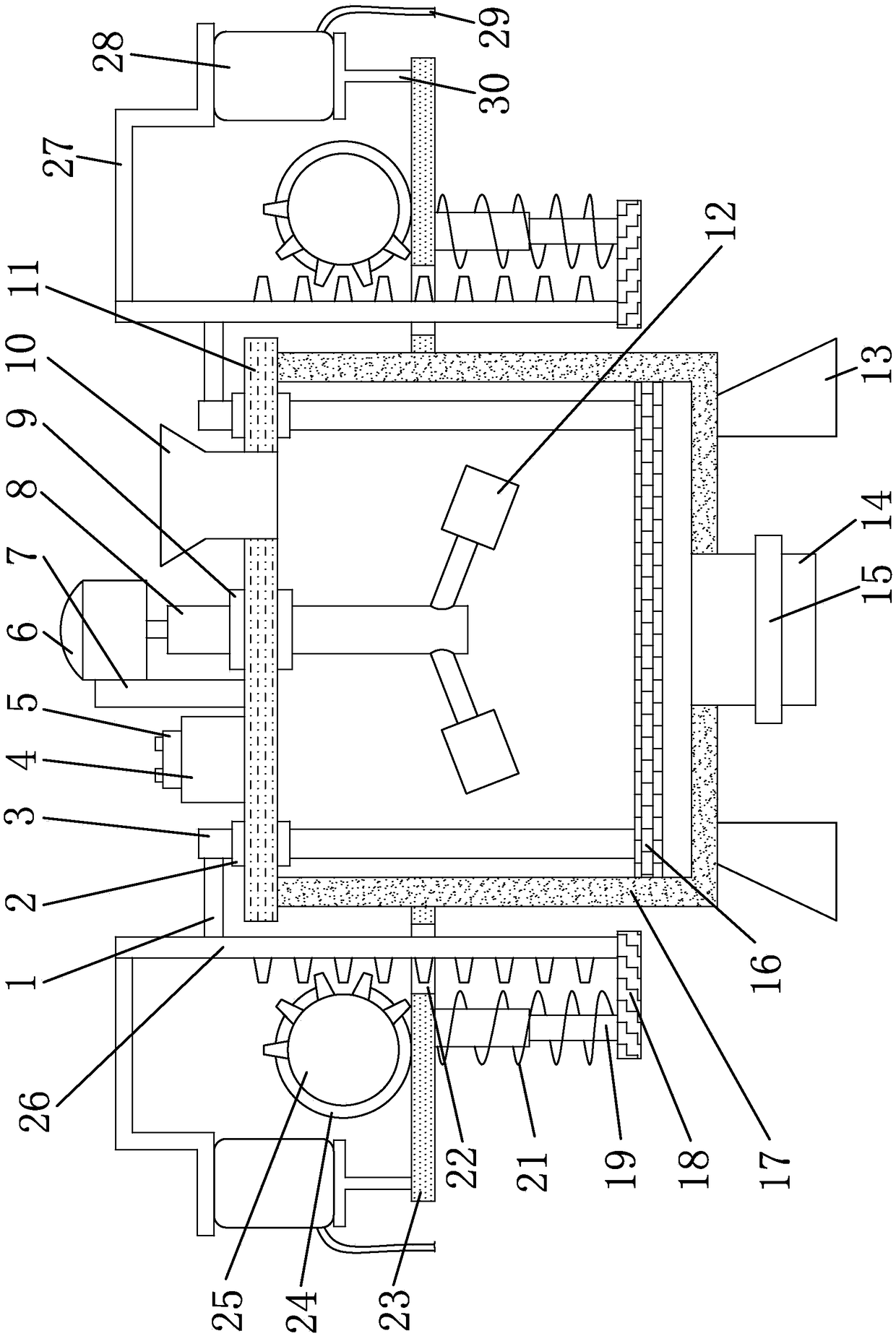

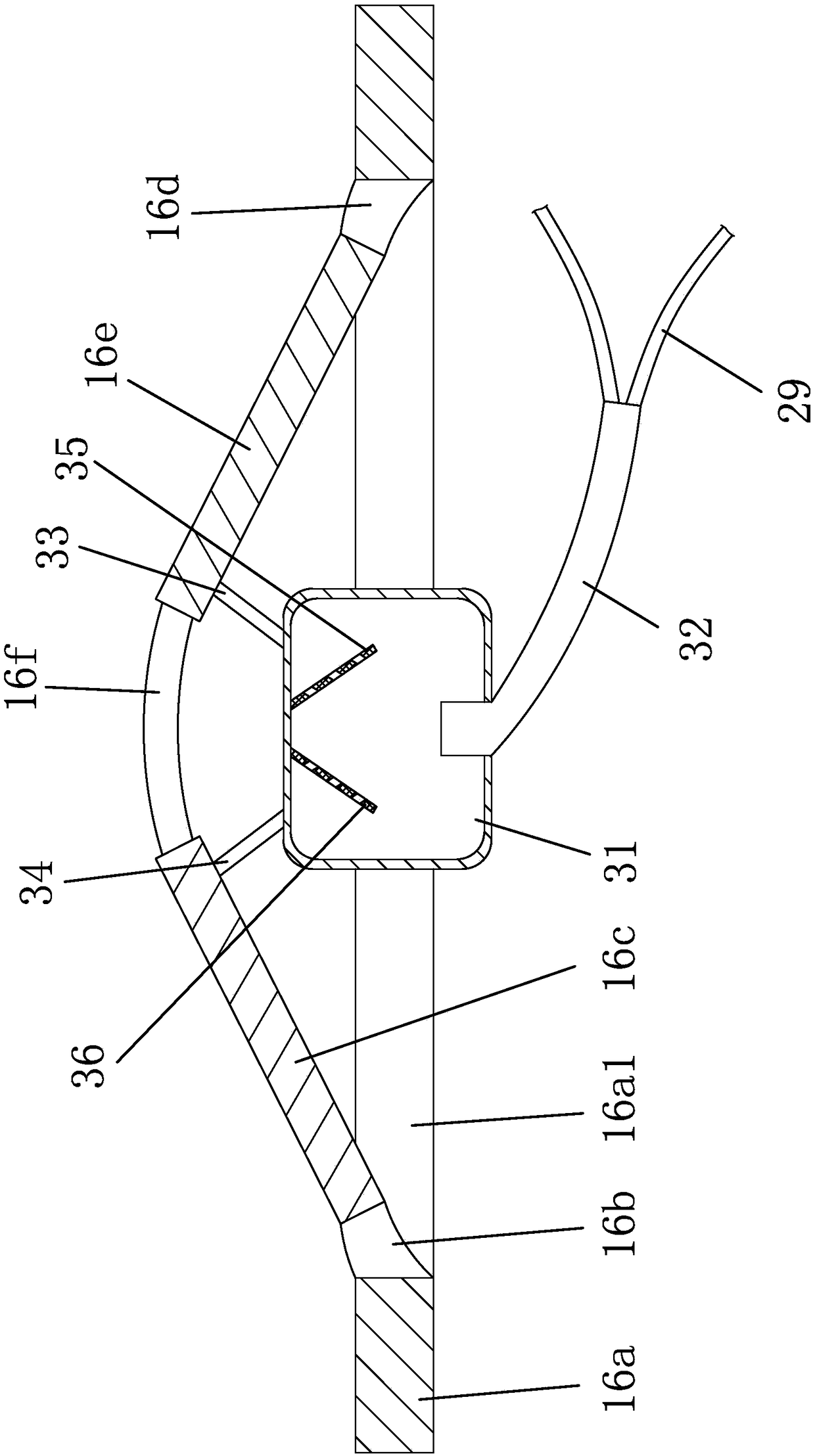

[0030] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

[0031] The treatment method of this industrial waste water, comprises the steps:

[0032] a, drop into precipitant in industrial waste water, and place 2-5h; In the present embodiment, drop into precipitant in industrial waste water, and place 3h;

[0033] B, filtering the industrial waste water in step a through a treatment device;

[0034] c. Filtering and adsorbing the industrial waste water in step b through activated carbon to obtain treated industrial waste water.

[0035] The precipitating agent in the step a comprises the following components according to weight percentage: 35-55% of sodium hydroxide, 8-20% of potassium hydroxide, 6-10% of diatomaceous earth, 3-16% of sodium carbonate, 1-11% of magnesium carbonate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com