Waste circulation type wood thermal cutting device

A circulating, thermal cutting technology, applied in grinding/polishing safety devices, grinding machines, charcoal burning/combustion, etc., can solve problems such as waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following is further described in detail through specific implementation methods:

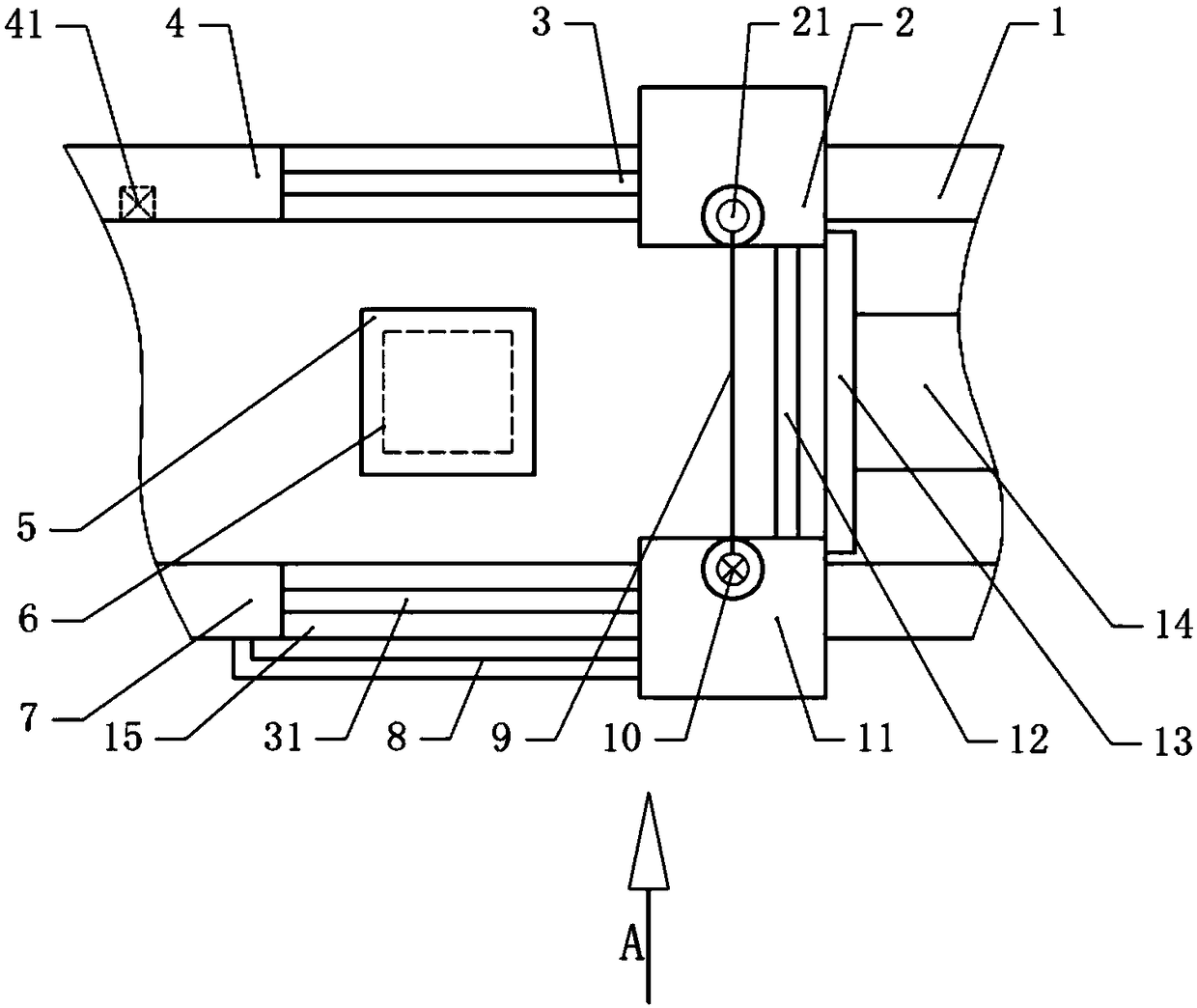

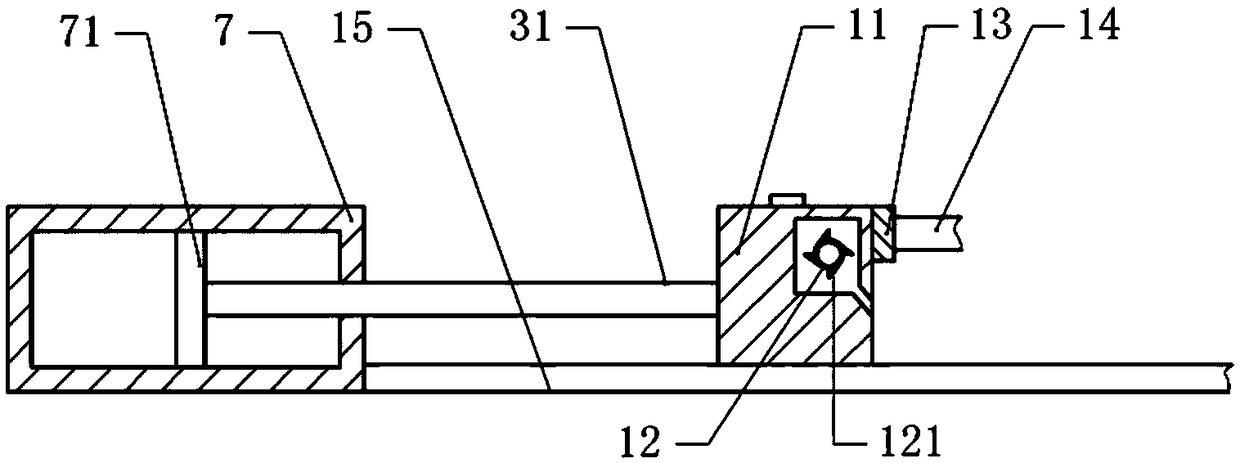

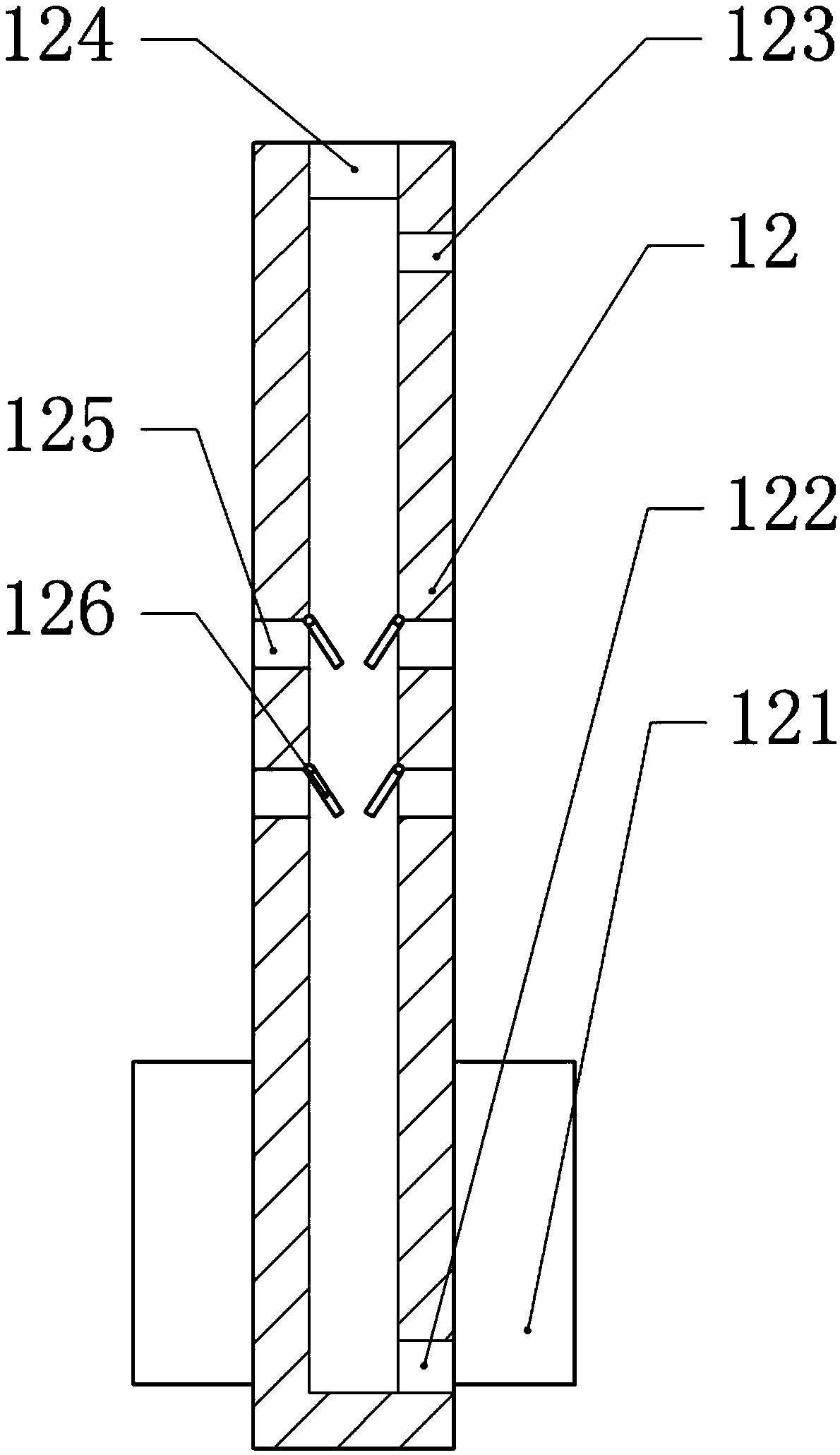

[0021] The reference signs in the drawings of the description include: the first slideway 1, the first slider 2, the connecting button 21, the first piston rod 3, the second piston rod 31, the first air box 4, the solenoid valve 41, the pressure plate 5 , wood 6, second air box 7, second piston plate 71, air pipe 8, alloy wire 9, heating device 10, second slider 11, polishing rod 12, fan blade 121, second outlet 122, first outlet 123 , inlet 124, opening 125, closing plate 126, connecting plate 13, output shaft 14, second slideway 15.

[0022] Waste recycling thermal wood cutting device, basically as attached figure 1 , comprising a frame and a first slideway 1 and a second slideway 15 arranged horizontally on the frame.

[0023] The right end of the first slideway 1 is horizontally slidably connected with the first slide block 2, and the left end of the first slideway 1 is fixed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com