Weak visible light response compound photocatalyst and preparation thereof and application thereof

A photocatalyst, visible light technology, applied in catalyst activation/preparation, physical/chemical process catalyst, metal/metal oxide/metal hydroxide catalyst, etc., can solve problems such as weak phenol, achieve easy operation, low cost, Simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

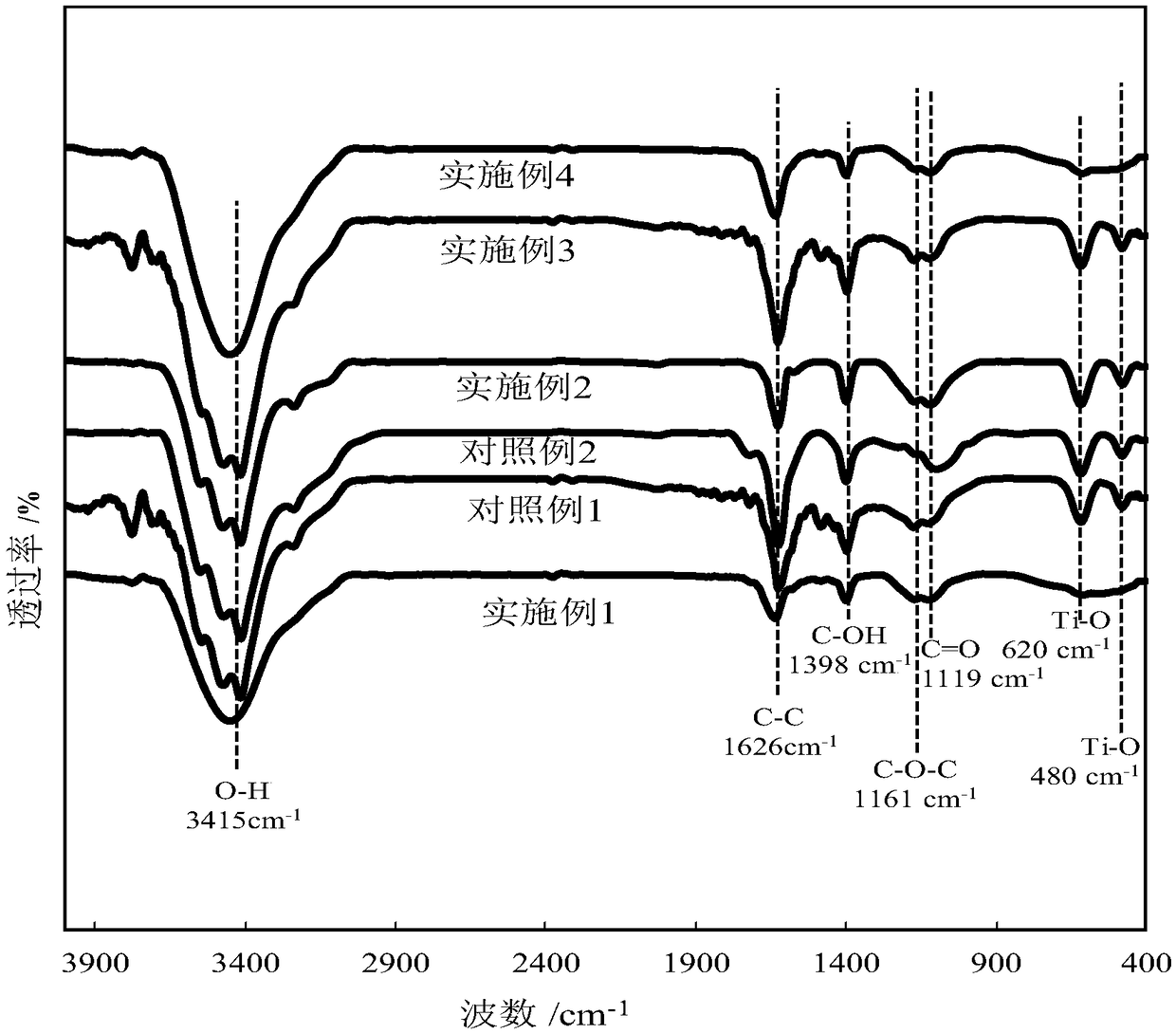

Embodiment 1

[0053] (1) Catalyst preparation

[0054] Dissolve 3.18 mg of lanthanum nitrate in 50 mL of absolute ethanol, stir in a water bath until it is completely dissolved, then quickly add 2.5 g of tetrabutyl titanate. Under the protection of nitrogen, the temperature of the water bath was raised to 80° C. and stirred for 2 hours, and then cooled to room temperature to form a composite reactant solution A (the atomic ratio of La and Ti was 0.1:100). Another 0.5g graphene oxide (specific surface area 50m 2 / g), 200mL of absolute ethanol and 1.5mL of deionized water were placed in a flask, stirred and adsorbed in a water bath at 30°C. After adsorption equilibrium (12 hours), a stable adsorption water layer was formed on the surface of graphene oxide, and finally adsorption system B was formed.

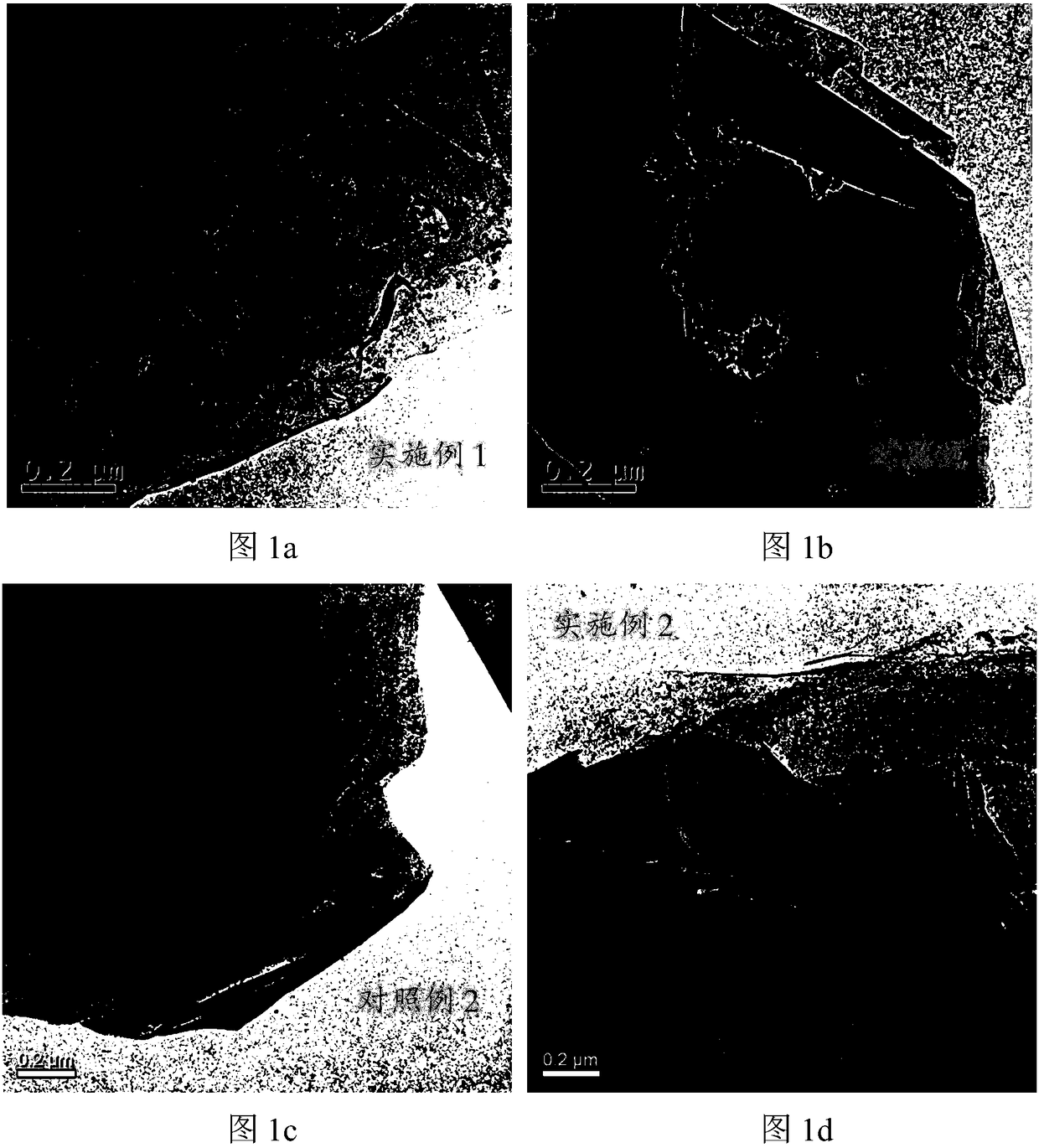

[0055] The reaction solution system A was dropped into the adsorption system B dropwise using a constant pressure funnel. The tetrabutyl titanate prepolymer doped with La ions diffuses into t...

Embodiment 2

[0098] (1) Catalyst preparation

[0099] Dissolve 6.36 mg of lanthanum nitrate in 50 mL of absolute ethanol, stir in a water bath until it is completely dissolved, and then quickly add 2.5 g of tetrabutyl titanate. Under the protection of nitrogen, the temperature of the water bath was raised to 80° C. and stirred for 2 hours, and then cooled to room temperature to form a composite reactant solution A (the atomic ratio of La and Ti was 0.1:100). Another 0.5g graphene oxide (specific surface area 50m 2 / g), 200mL of absolute ethanol and 1.5mL of deionized water were placed in a flask, stirred and adsorbed in a water bath at 30°C. After adsorption equilibrium (12 hours), a stable adsorption water layer was formed on the surface of graphene oxide, and finally adsorption system B was formed.

[0100] The reaction solution system A was dropped into the adsorption system B dropwise using a constant pressure funnel. The tetrabutyl titanate prepolymer doped with La ions diffuses in...

Embodiment 3

[0113] (1) Catalyst preparation

[0114] Dissolve 3.30 mg of ytterbium nitrate in 50 mL of absolute ethanol, stir in a water bath until it is completely dissolved, and then quickly add 2.5 g of tetrabutyl titanate. Under the protection of nitrogen, the temperature of the water bath was raised to 80° C. and stirred for 2 hours, and then cooled to room temperature to form a composite reactant solution A (the atomic ratio of La and Ti was 0.1:100). Another 0.5g graphene oxide (specific surface area 50m 2 / g), 200mL of absolute ethanol and 1.5mL of deionized water were placed in a flask, stirred and adsorbed in a water bath at 30°C. After adsorption equilibrium (12 hours), a stable adsorption water layer was formed on the surface of graphene oxide, and finally adsorption system B was formed.

[0115] The reaction solution system A was dropped into the adsorption system B dropwise using a constant pressure funnel. The tetrabutyl titanate prepolymer doped with Yb ions diffuses in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com