Oily powder paste with thixotropy and preparation method of oily powder paste

A toner and powder technology, applied in the field of cosmetic raw materials, can solve the problems of affecting the quality stability of downstream products, restricting the flexibility of formula design, and uneven powder content, so as to facilitate large-scale industrial production and reduce the risk of oil and powder separation , good oil compatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

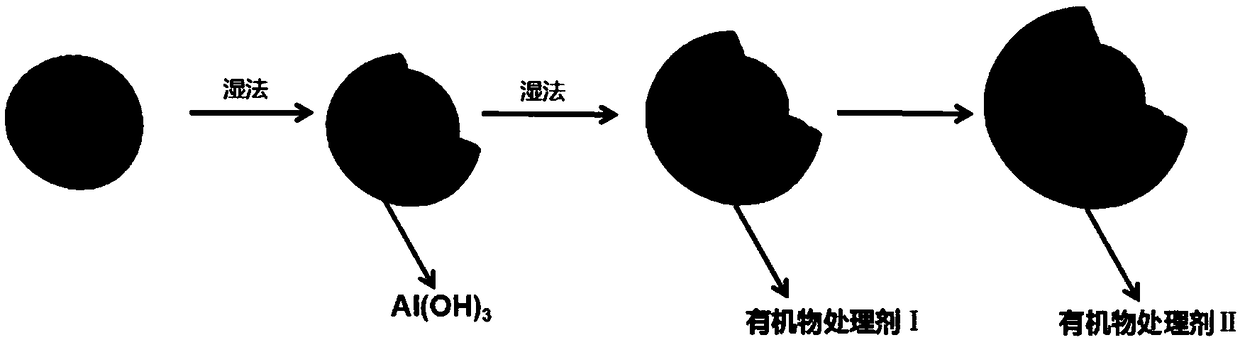

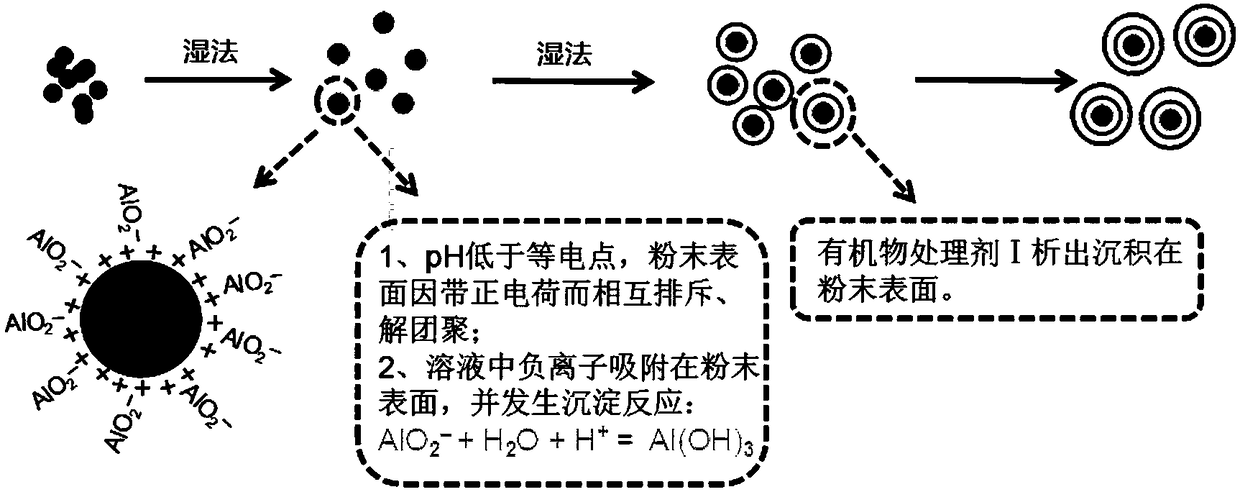

[0033] Add 2 g NaAlO to the round bottom flask 2With 250g of deionized water, stir until dissolved and clarified, add 150g of titanium dioxide, stir at 60°C for 15min, adjust pH=5.5 (25°C) with 3wt.% HCl solution, and mature for 15min; then add 100g of 2wt.% stearyl Add sodium glutamate aqueous solution to the above dispersion liquid, adjust pH=6.0 (25°C) with 3wt.% HCl solution, mature for 15 minutes, vacuum filter to obtain wet powder, dry at 115°C for 1.5h to obtain dry powder; put the above dry powder into high-speed Mixer, under high-speed stirring, spray triethoxyoctylsilane with a mass percentage of titanium dioxide of 3% into the high-speed mixer through an oil spray tank to mix triethoxyoctylsilane and powder evenly, bake at 120°C for 2 hours, and cool naturally Discharge, get the surface modified titanium dioxide toner, the reaction process is as attached figure 1 and 2 shown.

[0034] 66wt.% of the above-mentioned surface-modified titanium dioxide toner, 33wt.% o...

Embodiment 2

[0036] The titanium dioxide in Example 1 was replaced with iron oxide red, and other processes were basically the same to obtain a thixotropic iron oxide red powder slurry, wherein the mass content of iron oxide red powder was 65%.

Embodiment 3

[0038] The titanium dioxide in Example 1 was replaced with iron oxide yellow, and the other processes were basically the same to obtain a thixotropic iron oxide yellow powder slurry, wherein the iron oxide yellow powder content was 50%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com