A diaphragm, its preparation method and lithium battery

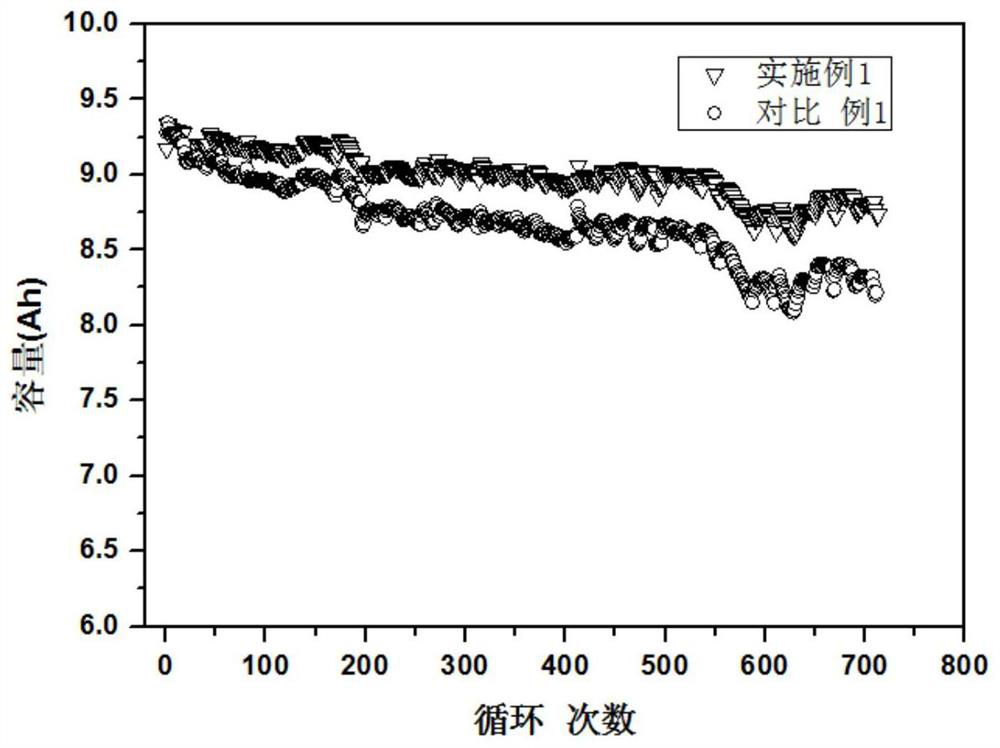

A diaphragm and coupling agent technology, which is applied in the field of diaphragm, its preparation and lithium battery, can solve the problems of decomposition, affecting the use of ceramic diaphragm, and unsatisfactory bonding effect, etc., and achieve good thermal stability and excellent cycle life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

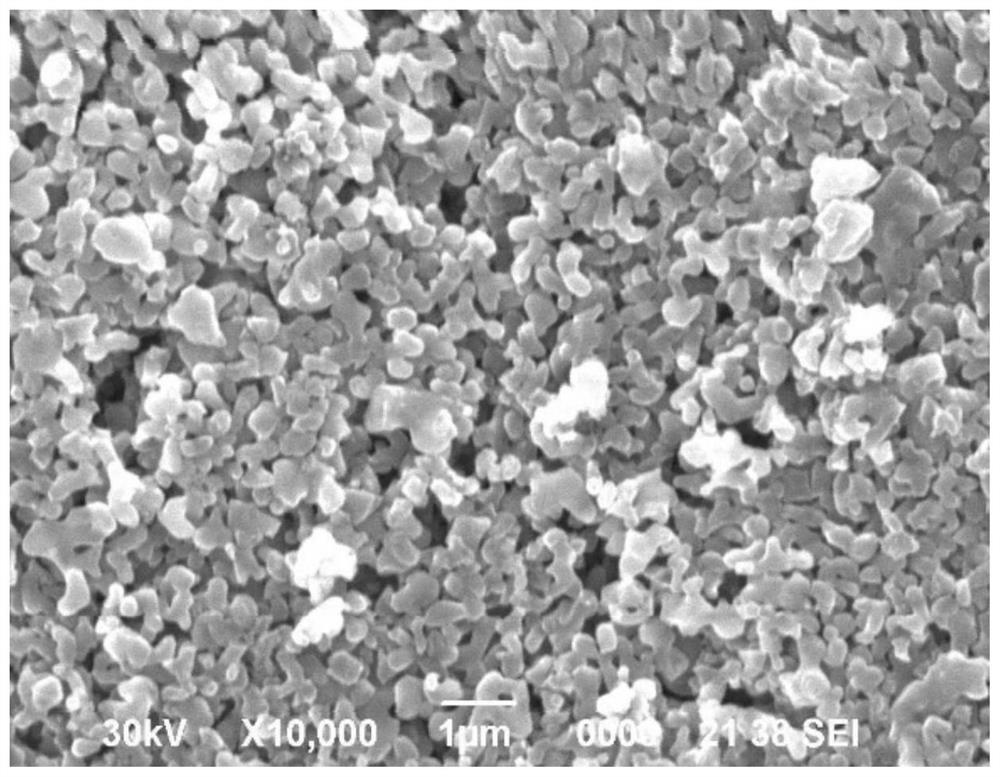

[0044] Raw materials γ-aminopropyltriethoxysilane, butanediol and water are mixed in a mass ratio of 20%:10%:70% to obtain a mixed solution, and the total mass of the raw materials is 1000g; nano-alumina particles, The dispersant polyacrylate and water were mixed in a mass ratio of 50%:2%:48% to obtain 400 g of a nano-alumina dispersion. The nano-alumina dispersion and the catalyst hydrochloric acid are added to the above mixed solution to form a slurry. The above slurry is coated on the surface of the aramid fiber diaphragm, and dried at 80° C. to obtain the diaphragm of the present invention.

[0045] Battery production: the binder polyvinylidene fluoride (PVDF) is dissolved in N-methylpyrrolidone to form a solution, conductive carbon black is added to the above PVDF solution, and stirred to form a uniform suspension; then the ternary positive electrode material (LiMn 1 / 3 co 1 / 3 Ni 1 / 3 o 2 ) was added to the above-mentioned suspension, and stirred to form a slurry; whe...

Embodiment 2

[0049] With embodiment 1, difference is that described catalyzer is ammoniacal liquor. Test results: The capacity retention rate after 713 cycles is 95.4%.

Embodiment 3

[0051] With embodiment 1, difference is that ceramic particle is nanometer Li 4 SiO 4 -B 2 o 3 . Test results: The capacity retention rate after 730 cycles is 96.2%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com