Heteropolyacid salt loaded cellulose porous material and preparation method thereof

A technology for heteropolyacid salts and porous materials, which is applied in the field of heteropolyacid salt supported cellulose porous materials and their preparation, can solve the problems of small specific surface area and low surface modification density of cellulose fabrics, and achieves low density and improved density. Mechanical properties, the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Get 10.0g solid content 1.2wt.% nanocellulose suspension, add 3-(2,3-epoxypropoxy)propyltrimethoxysilane (0.12g), polyethyleneimine (0.12g) , and stirred at room temperature for 4 h to obtain polyethyleneimine-modified cellulose nanowire suspension.

[0032] (2) Place the suspension prepared in (1) into liquid nitrogen for quick freezing, the cooling time is 10min, and then freeze-dry in a freeze dryer, the freezing time is 24 hours, the temperature is -30°C, and the pressure is 20Pa, Then put it in an oven and bake at 110° C. for 30 minutes to hydrolyze and crosslink the silane to obtain a polyethyleneimine-modified cellulose porous material.

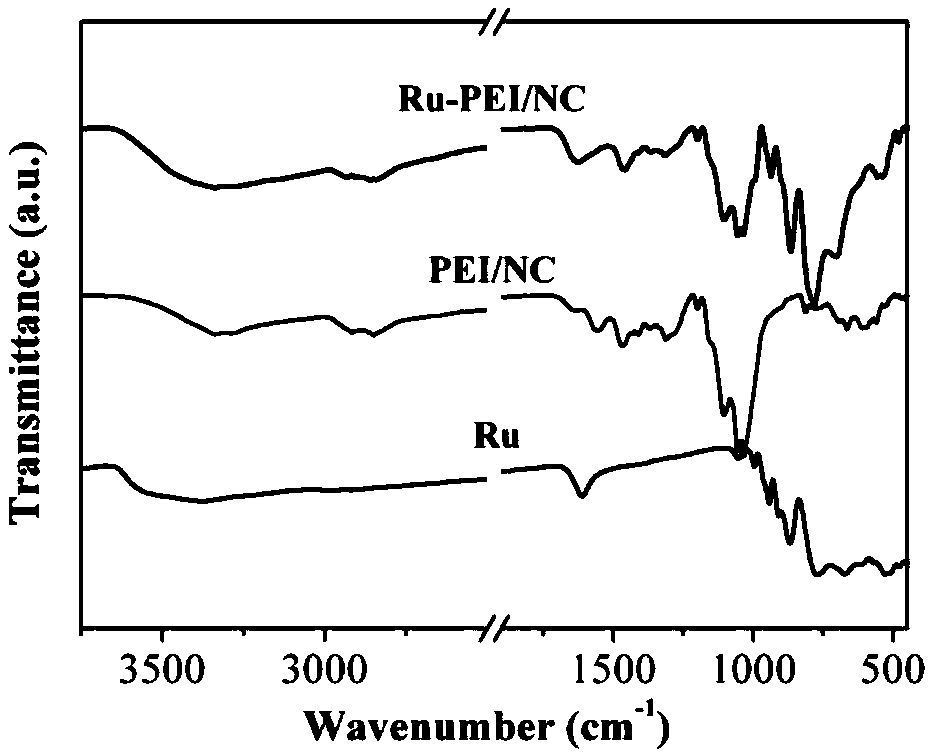

[0033] (3) Take the cellulose porous material and impregnate it in 2mg / mL Ru 4 In the heteropoly acid salt solution (mass ratio of cellulose porous material to heteropoly acid salt solution: 1:1000), use 12mol / L hydrochloric acid to adjust the pH value of the solution to 7.0, immerse for 12 hours, and temperature 25°C.

[...

Embodiment 2

[0039] (1) Get 10.0g solid content 1.2wt.% nanocellulose suspension, add 3-(2,3-epoxypropoxy)propyltrimethoxysilane (0.24g), polyethyleneimine (0.12g) , and stirred at room temperature for 4 h to obtain polyethyleneimine-modified cellulose nanowire suspension.

[0040] (2) Place the suspension prepared in (1) into liquid nitrogen for quick freezing, the cooling time is 10min, and then freeze-dry in a freeze dryer, the freezing time is 24 hours, the temperature is -30°C, and the pressure is 20Pa, Then put it in an oven and bake at 110° C. for 30 minutes to hydrolyze and crosslink the silane to obtain a polyethyleneimine-modified cellulose porous material.

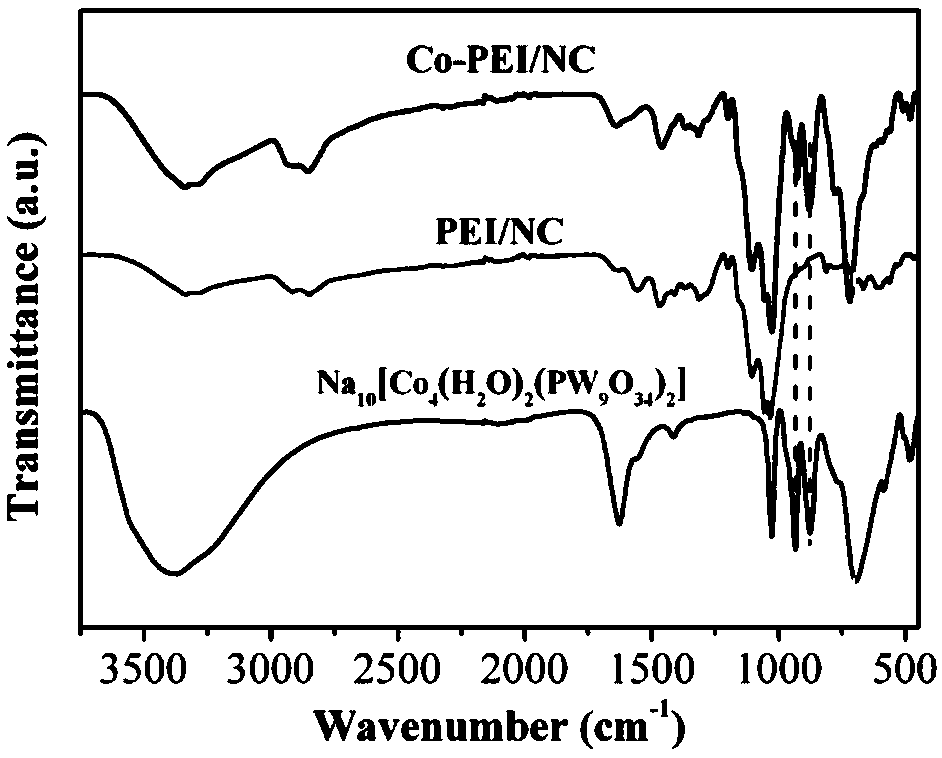

[0041] (3) Take the cellulose porous material and impregnate it in 2mg / mL Na 10 [Co 4 (H 2 O) 2 (PW 9 o 34 ) 2 ] In the heteropoly acid salt solution (the mass ratio of the cellulose porous material to the heteropoly acid salt solution is 1:1000), use 12mol / L hydrochloric acid to adjust the pH value of the solution to...

Embodiment 3

[0047] (1) Get 10.00g solid content 1.2wt.% nano-cellulose suspension, add 2-(3,4-epoxycyclohexyl) ethyltriethoxysilane (0.12g), polyethyleneimine ( 0.12 g), stirred at room temperature for 4 h to obtain polyethyleneimine modified cellulose nanowire suspension.

[0048] (2) Place the suspension prepared in (1) into liquid nitrogen for quick freezing, the cooling time is 10min, and then freeze-dry in a freeze dryer, the freezing time is 24 hours, the temperature is -30°C, and the pressure is 20Pa, Then put it in an oven and bake at 110° C. for 30 minutes to hydrolyze and crosslink the silane to obtain a polyethyleneimine-modified cellulose porous material.

[0049] (3) Take the cellulose porous material and impregnate it in 2mg / mL [(n-C 4 h 9 ) 4 N] 3 [H 3 V 10 o 28 ] In the heteropolyacid salt acetonitrile solution (mass ratio of cellulose porous material to heteropolyacid salt solution is 1:1000), use 12mol / L hydrochloric acid to adjust the pH value of the solution to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com