Preparation method of crack-resistant self-repairing concrete

A concrete and self-repairing technology, which is applied in the field of building material preparation, can solve problems such as difficult to find cracks, decline in concrete mechanical properties, and easy cracks, so as to inhibit the occurrence and development of cracks, ease stress concentration, and reduce stress intensity factor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

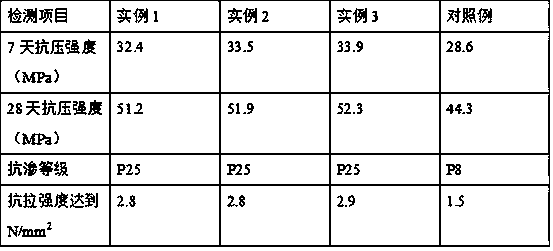

Examples

example 1

[0019] Mix the river bottom mud, lime milk and leaves in a mass ratio of 1:2:1 and put them into a ceramic tank as a fermentation substrate, add water to the ceramic tank along the wall of the ceramic tank until the fermentation substrate is completely submerged, and seal the fermentation Tank, sealed and fermented at a temperature of 30°C for 30 days; after the fermentation was completed, the fermentation product was taken out, and freeze-dried at -15°C with a vacuum freeze dryer to obtain a dried product, which was combined with a length of 5 mm and an aspect ratio of 30 steel fibers were mixed at a mass ratio of 1:2 to obtain self-made fillers; the waste glass was collected and put into a pulverizer to be pulverized and passed through a 200-mesh sieve to obtain sieved glass powder, which was then poured into a corundum crucible , then put the corundum crucible into the center of the silicon carbide rod resistance furnace, heat up to 1200°C at a rate of 10°C / min, and melt it ...

example 2

[0021] Mix the river bottom mud, lime milk and leaves in a mass ratio of 1:2:1 and put them into a ceramic tank as a fermentation substrate, add water to the ceramic tank along the wall of the ceramic tank until the fermentation substrate is completely submerged, and seal the fermentation tank, sealed and fermented at a temperature of 33°C for 35 days; after the end of the fermentation, the fermentation product was taken out and freeze-dried at -13°C with a vacuum freeze dryer to obtain a dried product. 33 steel fibers were mixed at a mass ratio of 1:2 to obtain self-made fillers; the waste glass was collected and put into a pulverizer to be pulverized and passed through a 200-mesh sieve to obtain sieved glass powder, which was then poured into a corundum crucible , and then put the corundum crucible into the center of the silicon carbide rod resistance furnace, heat up to 1250°C at a rate of 10°C / min, and melt it for 2 hours to obtain molten glass; inject the obtained molten g...

example 3

[0023]Mix the river bottom mud, lime milk and leaves in a mass ratio of 1:2:1 and put them into a ceramic tank as a fermentation substrate, add water to the ceramic tank along the wall of the ceramic tank until the fermentation substrate is completely submerged, and seal the fermentation tank, sealed and fermented at a temperature of 35°C for 40 days; after the end of fermentation, the fermentation product was taken out and freeze-dried at -10°C with a vacuum freeze dryer to obtain a dried product. 35 steel fibers were mixed at a mass ratio of 1:2 to obtain self-made fillers; the waste glass was collected and put into a pulverizer to be pulverized and passed through a 200-mesh sieve to collect sieved glass powder, which was then poured into a corundum crucible , then put the corundum crucible into the center of the silicon carbide rod resistance furnace, heat up to 1300°C at a rate of 10°C / min, and melt it for 3 hours to obtain molten glass; inject the obtained molten glass int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com