Treatment method and treatment system for desulfurization wastewater

A desulfurization wastewater treatment method technology, applied in water/sewage treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve high investment and operation costs, solid salt secondary pollution, water recovery Low efficiency and other problems, to achieve the effects of reducing investment and operating costs, high recovery rate of product water, and reducing drug consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

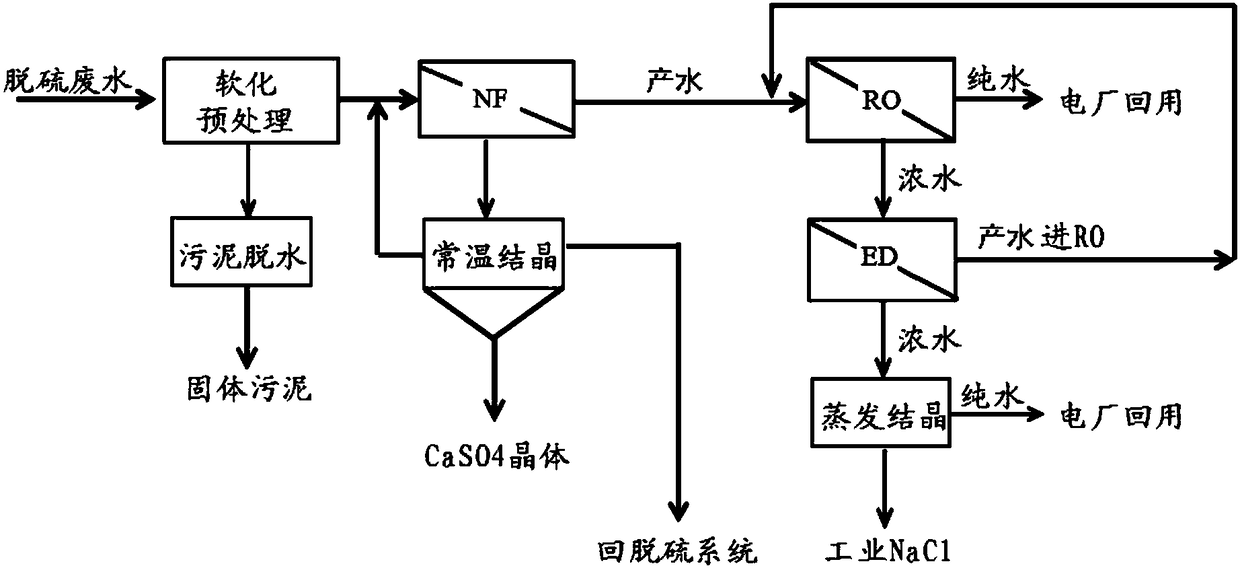

[0099] combine figure 1 , this embodiment is used to illustrate the treatment method of desalination wastewater of the present invention.

[0100] The softening pretreatment unit that uses in the present embodiment comprises 2 volumes and is 30m 3 The softening tank; the nanofiltration separation unit is a first-stage nanofiltration system consisting of 2 membrane shells and 24 GE DSL NF8040 nanofiltration membrane elements connected in series; the room temperature crystallization unit includes a volume of 10m 3 The stainless steel container and centrifugal separation device; the reverse osmosis separation unit is a one-stage reverse osmosis system consisting of a single membrane shell and six DOW BW30FR-400 reverse osmosis membrane elements connected in series; the electrodialysis separation unit includes a The total membrane area is 80m 2 The electrodialysis membrane stack and the corresponding auxiliary system; the crystallization separation unit includes a forced circul...

Embodiment 2

[0116] combine figure 2 , this embodiment is used to illustrate the treatment method of desalination wastewater of the present invention.

[0117] The treatment system of the desulfurization waste water of this embodiment is the same as that of Embodiment 1, and the influent flow rate of raw water is 20m 3 / h, the specific process is as follows:

[0118] (1) Set the flow rate described in Table 2 as 20m 3 / h, the synthetic brine with a total mass fraction of 3% of salt is supplied to the softening pretreatment unit for softening pretreatment, wherein the softening pretreatment method includes: introducing the synthetic brine into the first softening tank, adding the synthetic brine to the synthetic brine Joining flow is 2.5m 3 The calcium hydroxide solution (pH is adjusted to 11.1) of the 10 weight % of / h, left standstill clarification 60 minutes after reacting for 40 minutes; Then add the flocculant polyferric chloride of the organic sulfur TMT15 of 60mg / L, 18mg / L and 1...

Embodiment 3

[0131] combine figure 1 , this embodiment is used to illustrate the treatment method of desalination wastewater of the present invention.

[0132] The treatment system of the desulfurization waste water of this embodiment is the same as that of Embodiment 1, and the influent flow rate of raw water is 20m 3 / h, the specific process is as follows:

[0133] (1) Set the flow rate described in Table 3 as 20m 3 / h, the synthetic brine containing 1.8% of the total mass fraction of salt is supplied to the softening pretreatment unit for softening pretreatment, wherein the method of softening pretreatment includes: introducing the synthetic brine into the first softening tank, adding the synthetic brine to the synthetic brine The joining flow is 0.45m 3 10% by weight of calcium hydroxide solution (pH is adjusted to 11.3) per h, after reacting for 45 minutes, let it stand for clarification for 50 minutes; then add the flocculant polyaluminum sulfate of organic sulfur TMT-15, 20mg / L o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com