Method for preparing high-specific-surface-area activated carbon from blend coal of coke powder and/or quenched coke powder

A technology for preparing activated carbon and using coke powder, which is applied in chemical instruments and methods, water/sewage treatment, adsorption water/sewage treatment, etc. It can solve the problems of cumbersome post-treatment process, large amount of activator used, and low product quality. Achieve the effects of shortening production time, low ash content, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

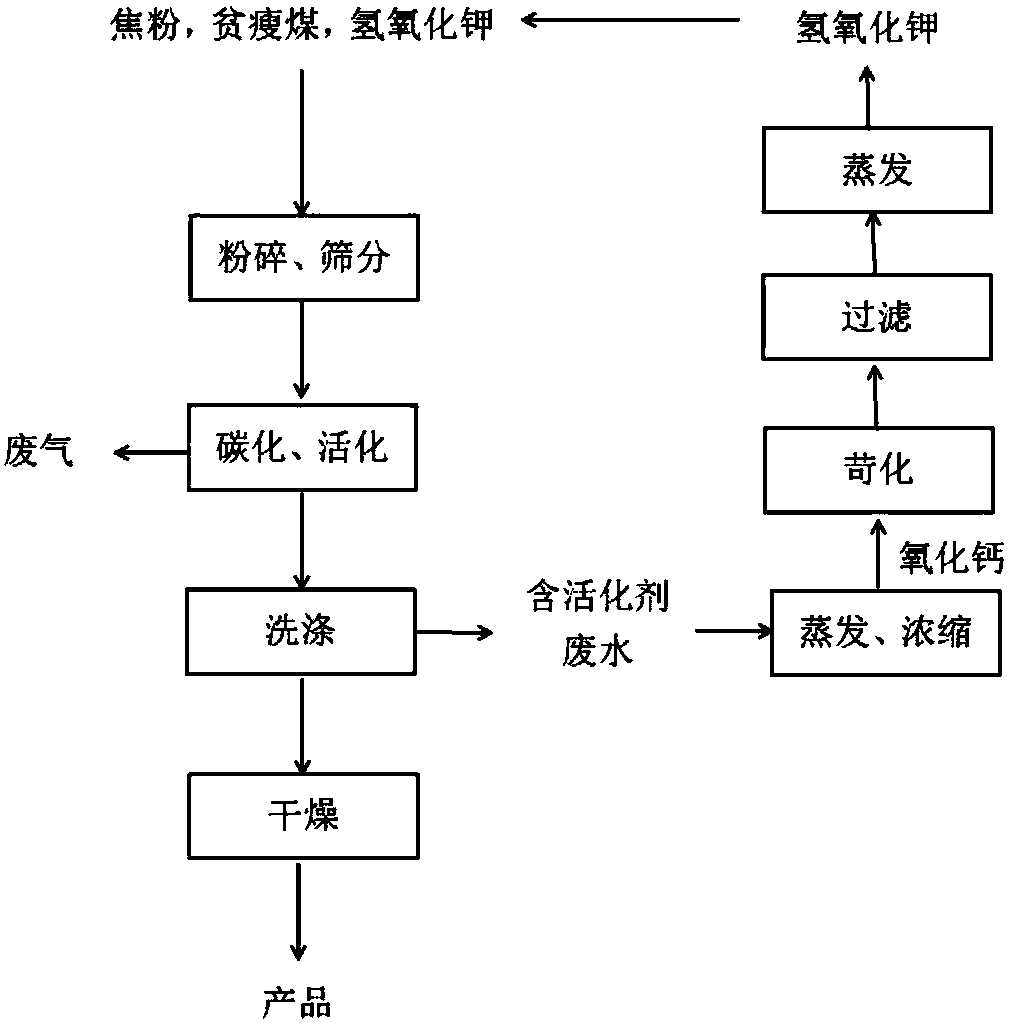

[0037] Prepare high specific surface area powdered activated carbon as follows:

[0038] (1) Coal blending: compound coke powder, lean coal and potassium hydroxide in a weight ratio of 2:1:1;

[0039] (2) Pulverization: pulverize the above-mentioned mixture to 120 mesh and 70% pass;

[0040] (3) Carbonization and activation: carbonize and activate the above pulverized mixture, the carbonization temperature is 550° C., and the carbonization time is 1 h. Subsequently, the temperature of the furnace was raised to 950° C., and activated for 1 h.

[0041] (4) Post-treatment: The carbonized and activated materials are washed with sulfuric acid and water until neutral, and then dried to obtain the product.

[0042] In addition, the activator-containing wastewater obtained after washing can be further treated to recycle potassium hydroxide. Potassium hydroxide can be recovered by subjecting activator-containing wastewater to evaporation, concentration, causticization, filtration an...

Embodiment 2

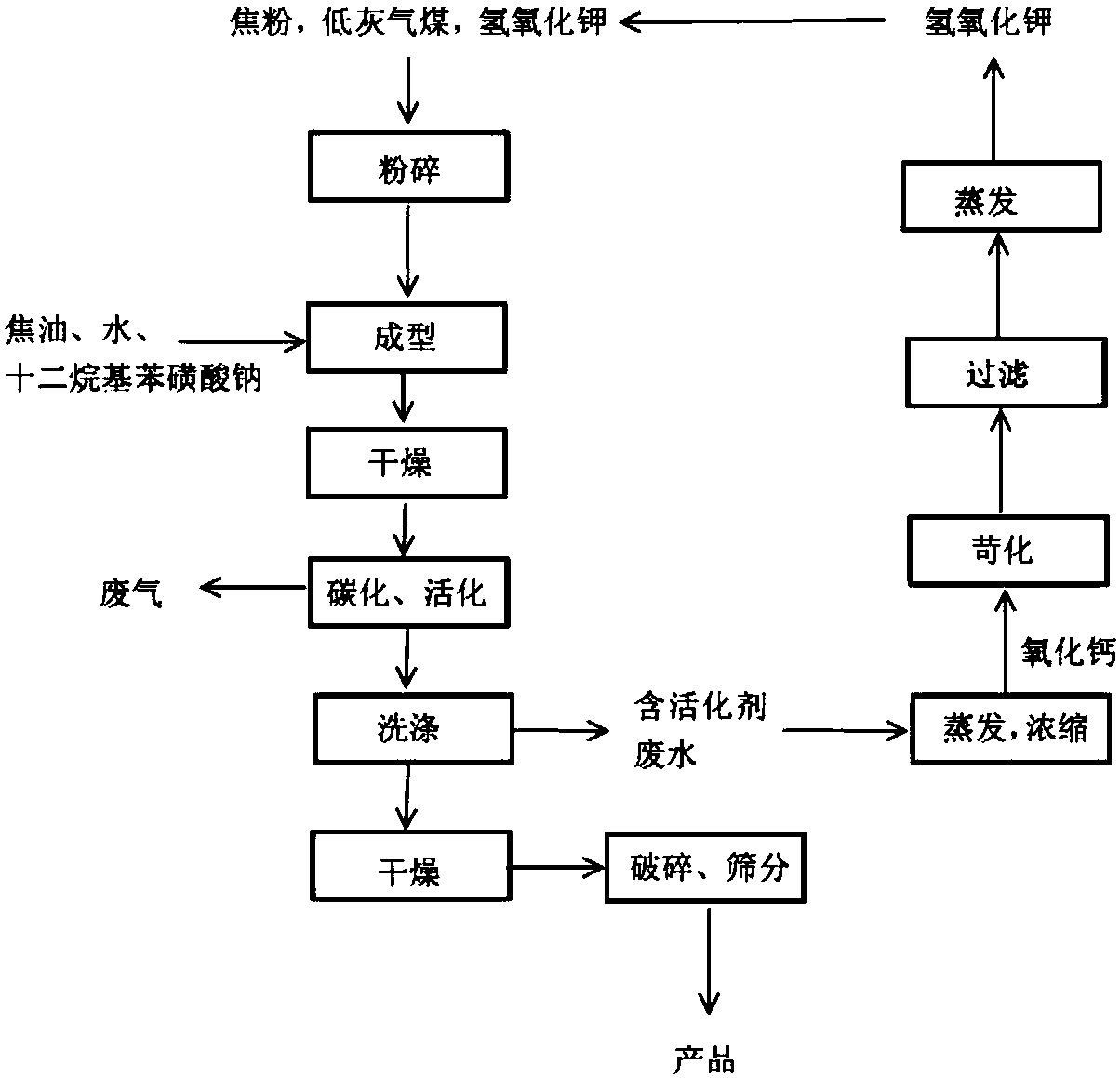

[0045] Prepare high specific surface area granular activated carbon according to the following steps:

[0046] (1) Coal blending: compound coke powder, low ash gas coal and potassium hydroxide in a weight ratio of 3:1:1;

[0047] (2) Pulverization: pulverize the above-mentioned mixture to 120 mesh and 70% pass;

[0048](3) Molding: transfer into the mixed powder and account for the tar of 3% of the gross weight of coke powder and low ash gas coal, the water of 5% and account for the dodecane of 0.05% of the gross weight of coke powder and low ash gas coal Sodium phenyl sulfonate, mixed uniformly and sent to the equipment to extrude;

[0049] (4) Drying: Dry the formed strips at 80°C to 90°C for 6 hours;

[0050] (5) Carbonization and activation: carbonize and activate the above pulverized mixture, the carbonization temperature is 600° C., and the carbonization time is 2.0 h. Subsequently, the furnace temperature was raised to 850° C., and activated for 1.2 h.

[0051] (6) ...

Embodiment 3

[0055] Prepare high specific surface area powdered activated carbon as follows:

[0056] (1) Coal blending: compound with coke quenching powder, lignin, sodium hydroxide and sodium carbonate in a weight ratio of 4:2:1:1;

[0057] (2) Pulverization: pulverize the above-mentioned mixture to 120 mesh and 70% pass;

[0058] (3) Carbonization and activation: carbonize and activate the above pulverized mixture, the carbonization temperature is 600° C., and the carbonization time is 2.0 h. Subsequently, the furnace temperature was raised to 850° C., and activated for 1.2 h.

[0059] (4) post-treatment: the material after being discharged from the oven is washed with dilute hydrochloric acid and water to neutrality in turn, and the product can be obtained after drying.

[0060] After testing, the activated carbon products produced by this process have a BET specific surface area greater than 1900m 2 / g, well-developed mesopores, and ash content below 1%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com