Contact-type displacement sensor structure based on 3D printing and making method thereof

A displacement sensor and 3D printing technology, applied in 3D object support structures, instruments, additive manufacturing, etc., can solve problems such as difficult to process structures with true three-dimensional free shapes, and achieve saving optimization, low raw material costs, and good molding accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

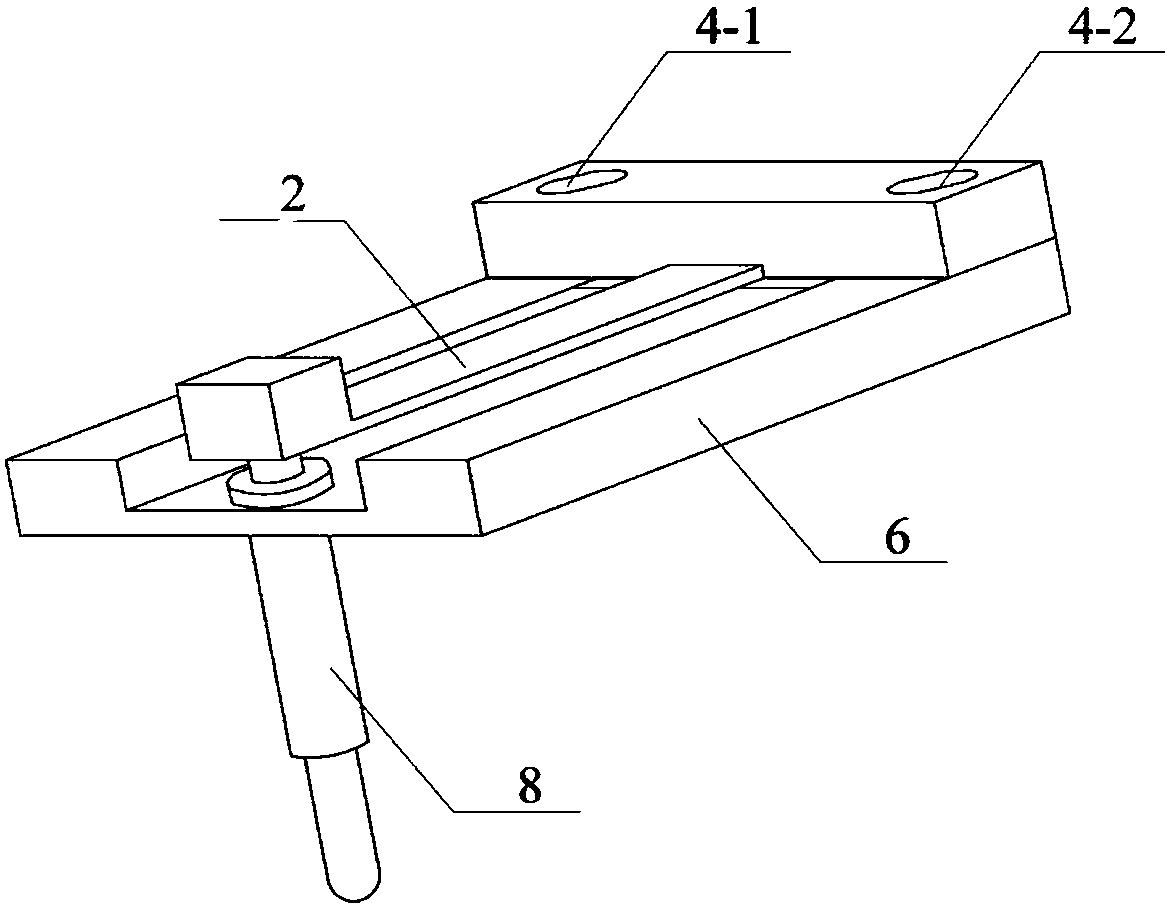

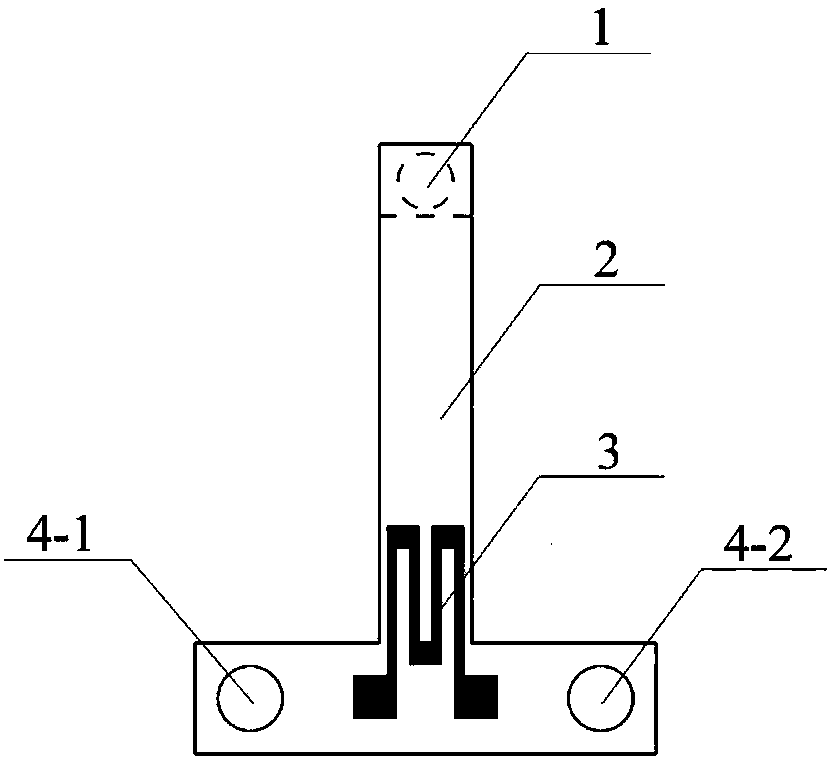

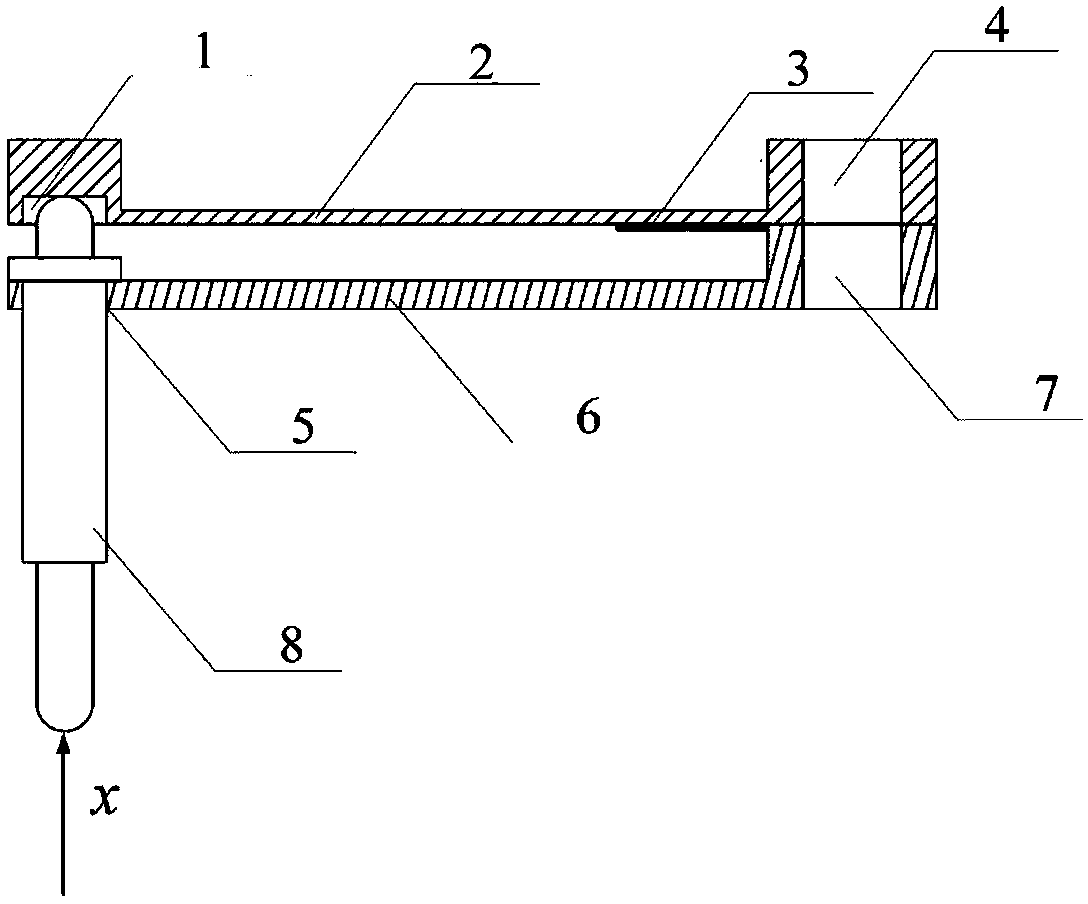

[0025] like figure 1 , figure 2 , image 3 As shown, a contact displacement sensor structure based on 3D printing includes a base structure 6, one end of the base structure 6 is provided with two second fixing holes 7, the other end is provided with a guide hole 5, and the base structure 6 is connected with a In the cantilever beam structure 2, the two second fixing holes 7 of the base structure 6 are aligned with the two first fixing holes 4 at the end of the cantilever beam structure 2, and the two first fixing holes 4 are respectively the first fixing holes 4-1, 4 -2, the end of the cantilever beam structure 2 is provided with a strain gauge structure 3, the head end of the cantilever beam structure 2 is provided with a limit hole 1, the probe 8 passes through the guide hole 5 on the base structure 6, and the upper end of the probe 8 is located ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com