Water and gas coupled valve of gas water heater

A gas water heater, water and gas linkage technology, applied in the direction of fluid heaters, valve devices, valve details, etc., can solve problems such as increased water flow resistance, water valve damage, complex structure, etc., and achieve the effect of reducing raw material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

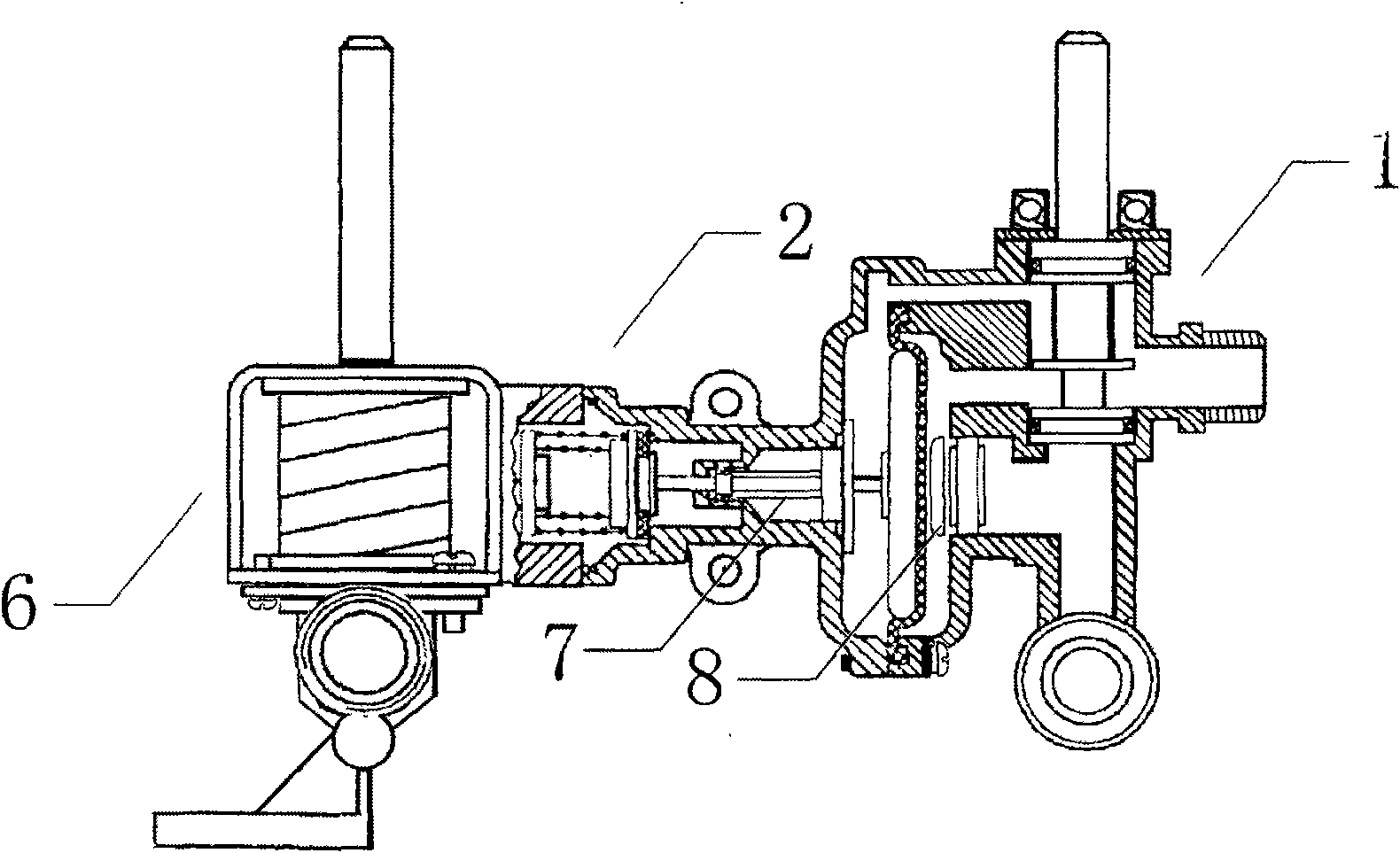

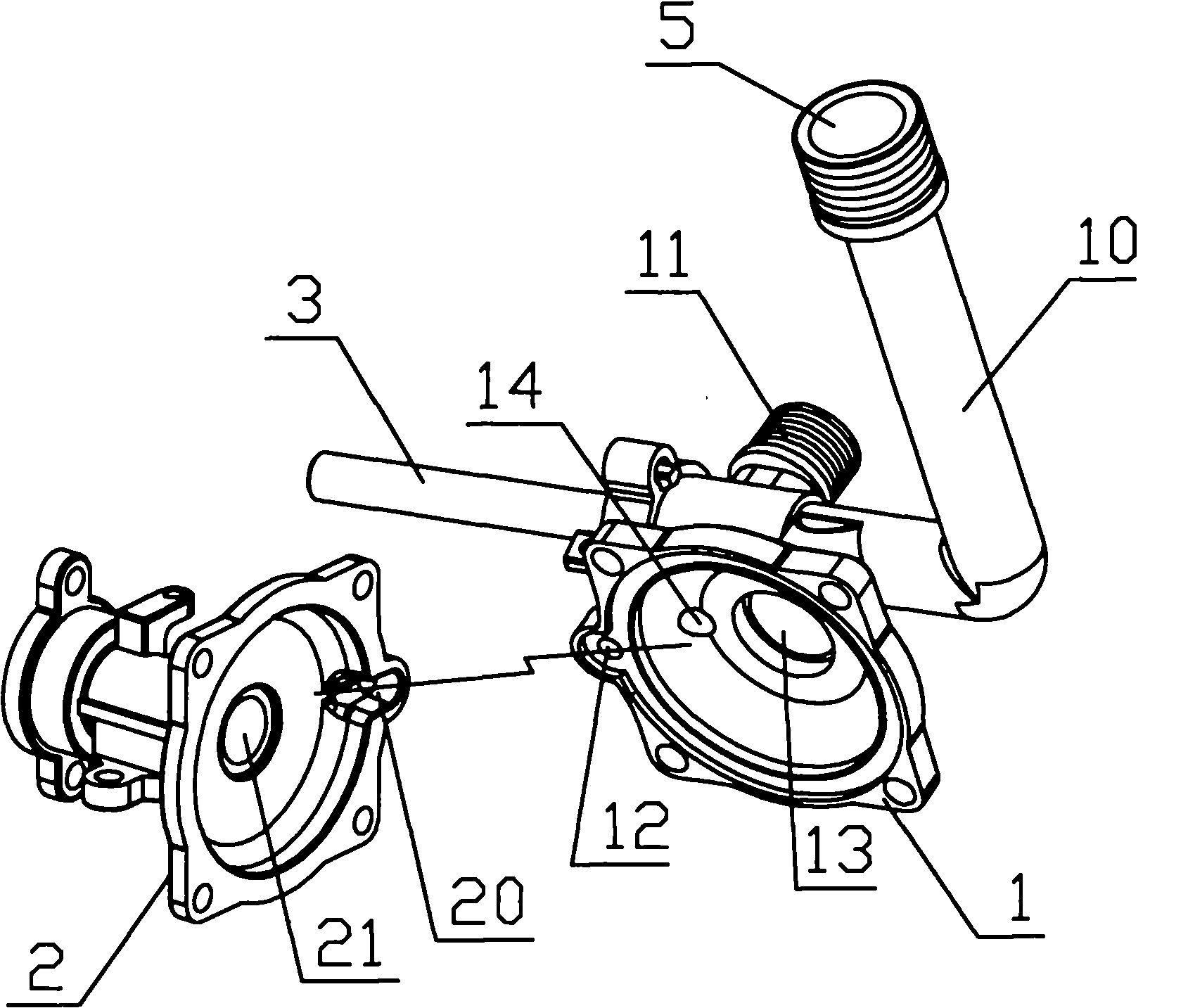

[0023] Specific implementation methods: such as Figure 1-Figure 5 As shown, the gas-fired water heater water-gas linkage valve of the present invention is mainly composed of a gas valve 6, a water valve and an intermediate water-gas linkage device, and the shell 1 of the water valve and the shell 2 of the water-gas linkage The diversion passage includes a diversion groove 12 provided on the water valve body 1 and another diversion groove 20 provided on the casing 2 of the water-air linkage device, and the two diversion grooves are arranged oppositely. They communicate with each other, and the diversion groove 12 on the water valve body 1 is in the same axial direction as the water outlet 11, which facilitates demoulding. The housing 2 center of the water-air linkage device has a through hole 21, and a linkage push rod 7 is installed on the through hole 21. In order to reduce the cost of materials and reduce the difficulty of the manufacturing process, the housing 1 of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com