Ladle lining repair material as well as preparation method and application thereof

A repairing material and lining technology, which is applied in the field of refractory materials, can solve the problems of high cost and unfriendly environment, and achieve the effects of improving service life, being friendly to the environment and having strong corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

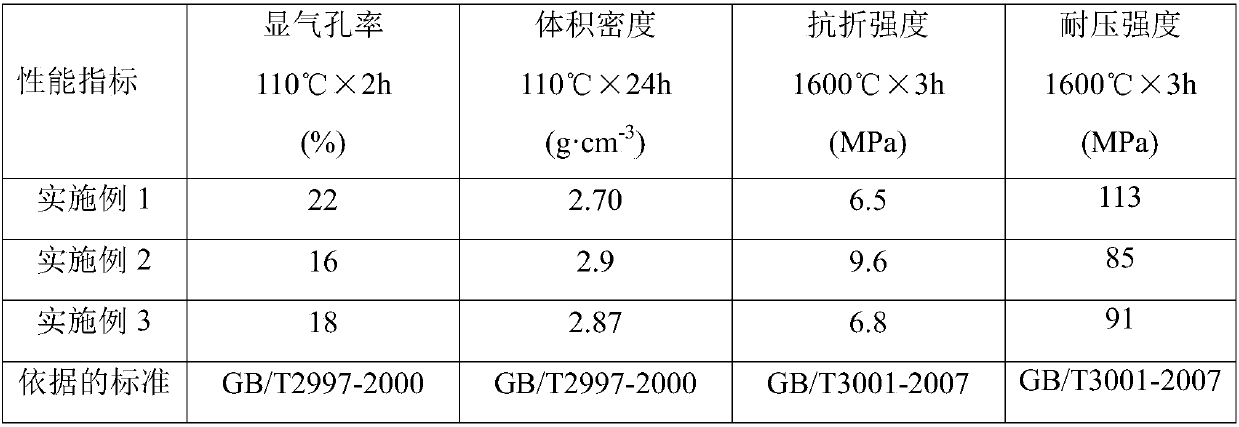

Examples

Embodiment 1

[0026] A ladle lining repair material, expressed in weight percent, consists of the following raw materials:

[0027] 35% of regenerated corundum aggregate of 5-3mm, 15% of regenerated corundum aggregate of 3-1mm, 20% of regenerated corundum aggregate of 1-0mm, 10% of corundum fine powder 2 o 3 Micropowder 4%; additionally add 0.2% sodium tripolyphosphate accounting for the total weight of the above raw materials as a water reducer and 0.1% explosion-proof fiber (diameter 40 μm, length 2-3 mm).

Embodiment 2

[0029] A ladle lining repair material, expressed in weight percent, consists of the following raw materials:

[0030] 30% of regenerated corundum aggregate of 5-3mm, 10% of regenerated corundum aggregate of 3-1mm, 15% of regenerated corundum aggregate of 1-0mm, 15% of corundum fine powder 2 o 3 Micropowder 6%; additionally add 0.2% sodium hexametaphosphate accounting for the total weight of the above raw materials as a water reducer and 0.1% explosion-proof fiber (diameter 40 μm, length 2-3 mm).

Embodiment 3

[0032] A ladle lining repair material, expressed in weight percent, consists of the following raw materials:

[0033] 25% of regenerated corundum aggregate of 5-3mm, 15% of regenerated corundum aggregate of 3-1mm, 20% of regenerated corundum aggregate of 1-0mm, 15% of corundum fine powder 2 o 3 Micropowder 5%; additionally add 0.2% sodium tripolyphosphate accounting for the total weight of the above raw materials as a water reducer and 0.1% explosion-proof fiber (diameter 60 μm, length 2-3 mm).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com