GAP propellant preparation method for laser micropropulsion

A propellant and micro-propulsion technology, which is used in offensive equipment, compressed gas generation, non-explosive/non-thermal composition, etc., and can solve problems such as affecting ablation efficiency, wasting laser energy, and excessive porosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

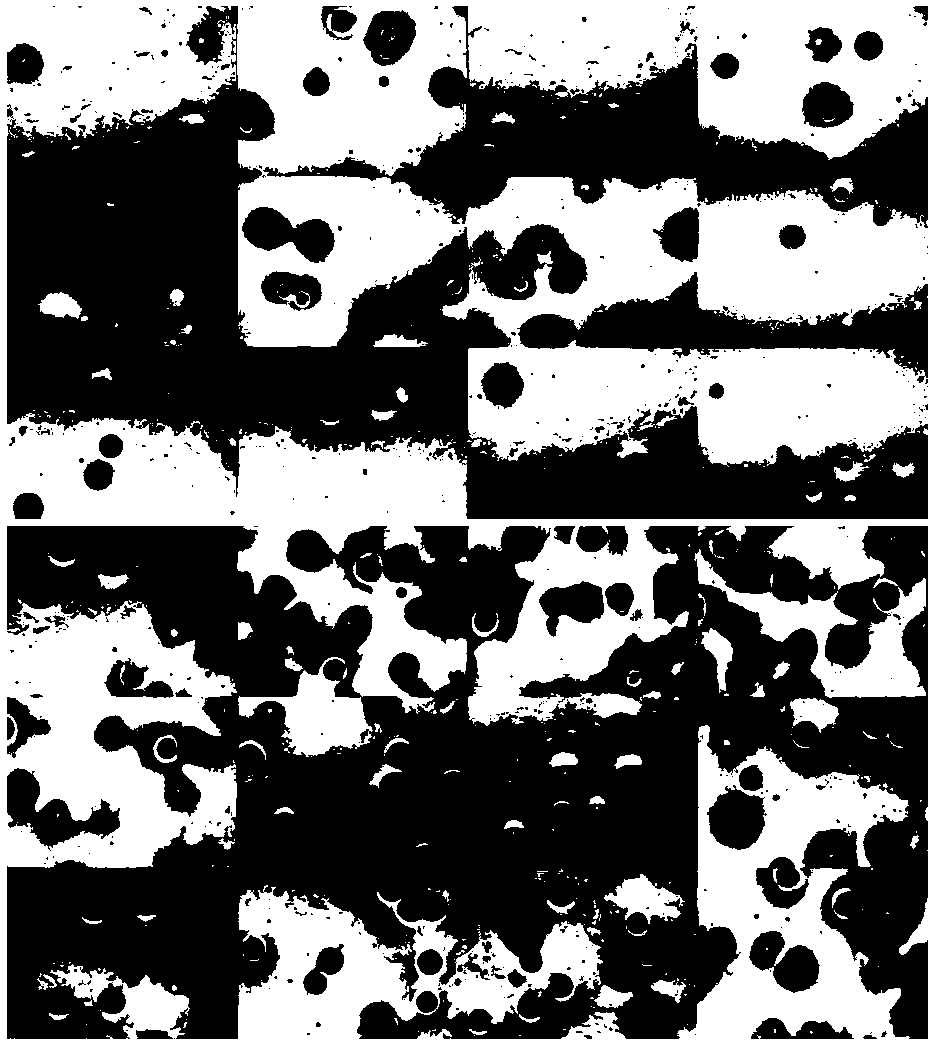

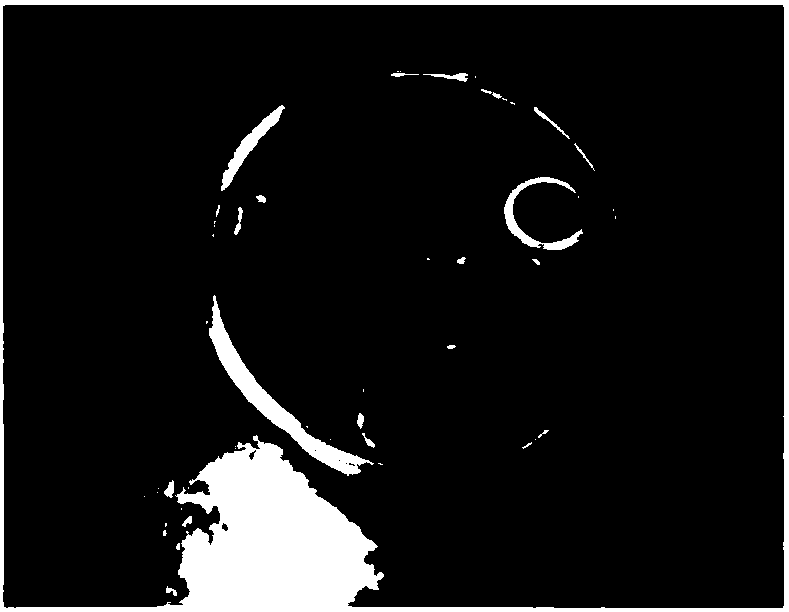

Image

Examples

Embodiment 1

[0032] In this embodiment, the vacuum oven model used is DZF-6030 of Shanghai Jinghong Experimental Equipment Co., Ltd., the GAP used was purchased from Henan Luoyang Liming Chemical Co., Ltd., and the nano C powder used (product number C109965 | CAS number 7440-44-0 |purity 99.5%|particle size 30nm), IPDI (product number I109582|CAS number 4098-71-9|purity 99%), TPB (product number T111431|CAS number 603-33-8|purity 98%), DBTDL ( Product No. D100274|CAS No. 77-58-7|purity 95%) and resorcinol (product No. R111662|CAS No. 108-46-3|AR purity 99%) were purchased from Aladdin Industries, USA;

[0033] Step Ⅰ: Pour the GAP solution into a polytetrafluoroethylene petri dish with a diameter of 20 cm, and spread it flat. Dry in a vacuum oven for 24 hours, and the temperature of the oven is kept at 60°C. At the same time, in order to prevent moisture from entering the GAP, a silica gel desiccant was added to the oven to obtain a dehydrated GAP solution;

[0034] Step II: Mix 10.0 g o...

Embodiment 2

[0042] In this embodiment, the vacuum oven model used is DZF-6030 of Shanghai Jinghong Experimental Equipment Co., Ltd., the GAP used was purchased from Henan Luoyang Liming Chemical Co., Ltd., and the nano C powder used (product number C109965 | CAS number 7440-44-0 |purity 99.5%|particle size 30nm), IPDI (product number I109582|CAS number 4098-71-9|purity 99%), TPB (product number T111431|CAS number 603-33-8|purity 98%), DBTDL ( Product No. D100274|CAS No. 77-58-7|purity 95%) and resorcinol (product No. R111662|CAS No. 108-46-3|AR purity 99%) were purchased from Aladdin Industries, USA;

[0043] Step Ⅰ: Pour the GAP solution into a polytetrafluoroethylene petri dish with a diameter of 20 cm, and spread it flat. Dry in a vacuum oven for 24 hours, and the temperature of the oven is kept at 60°C. At the same time, in order to prevent moisture from entering the GAP, a silica gel desiccant was added to the oven to obtain a dehydrated GAP solution;

[0044] Step II: Mix 10.0 g o...

Embodiment 3

[0052] In this embodiment, the vacuum oven model used is DZF-6030 of Shanghai Jinghong Experimental Equipment Co., Ltd., the GAP used was purchased from Henan Luoyang Liming Chemical Co., Ltd., and the nano C powder used (product number C109965 | CAS number 7440-44-0 |purity 99.5%|particle size 30nm), IPDI (product number I109582|CAS number 4098-71-9|purity 99%), TPB (product number T111431|CAS number 603-33-8|purity 98%), DBTDL ( Product No. D100274|CAS No. 77-58-7|purity 95%) and resorcinol (product No. R111662|CAS No. 108-46-3|AR purity 99%) were purchased from Aladdin Industries, USA;

[0053] Step Ⅰ: Pour the GAP solution into a polytetrafluoroethylene petri dish with a diameter of 20 cm, and spread it flat. Dry in a vacuum oven for 24 hours, and the temperature of the oven is kept at 60°C. At the same time, in order to prevent moisture from entering the GAP, a silica gel desiccant was added to the oven to obtain a dehydrated GAP solution;

[0054] Step II: Mix 10.0 g o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com