Metal catalyst for dehydrogenation of light alkane and preparation method and application thereof

A metal catalyst, low carbon alkane technology, used in metal/metal oxide/metal hydroxide catalysts, hydrocarbons, hydrocarbons, etc. problem, to achieve the effect of high conversion rate per pass, good regeneration performance, and high comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

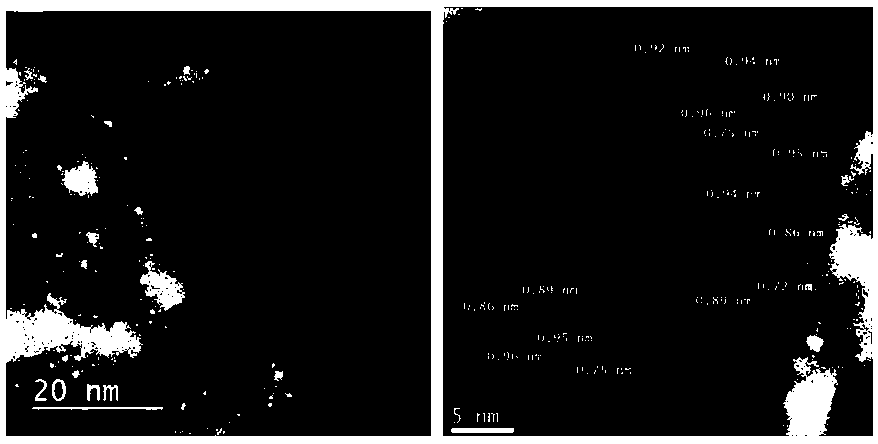

Image

Examples

Embodiment 1

[0027] Weigh 5.00 g of aluminum oxide (Al 2 o 3 ), put it into a 100 mL glass tube, and treat it in a heating furnace at 300 °C for 12 h under a nitrogen atmosphere. After heat treatment, dehydrated and deoxidized Al 2 o 3 As a carrier; then 0.043 g of Pt compound (Pt(COD)(Me) 2 ) and 0.037 g Sn compound (HSnBu 3 ) were sequentially immobilized on the surface of the carrier, the immobilization reaction temperature was 50°C, and the reaction time was 3h to obtain the catalyst precursor; finally, the catalyst precursor was reduced in a hydrogen atmosphere at 120°C for 4h to obtain the Pt-Sn / Al 2 o 3 catalyst. In a fixed-bed tubular reactor filled with 1 g of the catalyst prepared in Example 1, the reactant is propane, the reaction temperature is 550 ° C, the reaction pressure is normal pressure, and the propane weight hourly space velocity is 8 h -1 , under the condition that the ratio of hydrogen to hydrocarbon is 1, the conversion rate of propane is 36%, and the selectiv...

Embodiment 2

[0030] Weigh 5.00 g of silicon dioxide (SiO 2 ), put it into a 100 mL glass tube, and treat it in a heating furnace at 400 °C for 12 h under a nitrogen atmosphere. After heat treatment, dehydrated and deoxidized SiO 2 As a carrier; then 0.048 g of Pt compound (Pt(COD)Cl 2 ) and 0.042 g Ge compounds (Ge(Me) 4 ) were sequentially immobilized on the surface of the carrier, the immobilization reaction temperature was 40 °C, and the reaction time was 4 h to obtain the catalyst precursor; finally, the catalyst precursor was reduced in a hydrogen atmosphere at 160 °C for 4 h to obtain the Pt-Ge / SiO 2 catalyst. In a fixed-bed tubular reactor filled with 1 g of the catalyst prepared in Example 2, the reactant is propane, the reaction temperature is 550 ° C, the reaction pressure is normal pressure, and the propane weight hourly space velocity is 5 h -1 , under the condition that the ratio of hydrogen to hydrocarbon is 1, the conversion rate of propane is 34%, and the selectivity of ...

Embodiment 3

[0032] Weigh 3.00 g of magnesium oxide (MgO), put it into a 100 mL glass tube, and treat it in a heating furnace at 500 °C for 12 h under nitrogen atmosphere. After heat treatment, dehydrated and deoxidized MgO is obtained as a carrier; then 0.048 g Rh Compounds (Rh(COD) 2 Cl 2) and 0.037 g Sn compound (HSnPh 3 ) were sequentially immobilized on the surface of the carrier, the immobilization reaction temperature was 60 °C, and the reaction time was 5 h to obtain the catalyst precursor; finally, the catalyst precursor was reduced in a hydrogen atmosphere at 150 °C for 3 h to obtain the Rh-Sn / MgO catalyst. In a fixed-bed tubular reactor filled with 1 g of the catalyst prepared in Example 3, the reactant is propane, the reaction temperature is 550 ° C, the reaction pressure is normal pressure, and the propane weight hourly space velocity is 4 h -1 , under the condition that the ratio of hydrogen to hydrocarbon is 1, the conversion rate of propane is 37%, and the selectivity of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com