Pretreatment purifying method for gas chromatography-mass spectrometry pesticide residue detection

A technology for pesticide residue detection and GC-MS, which is applied in the direction of measuring devices, instruments, scientific instruments, etc., can solve the problems of consuming more organic matter, frequent instrument maintenance, and high purification costs, and achieve low detection costs, reduced maintenance frequency, The effect of reducing inspection costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

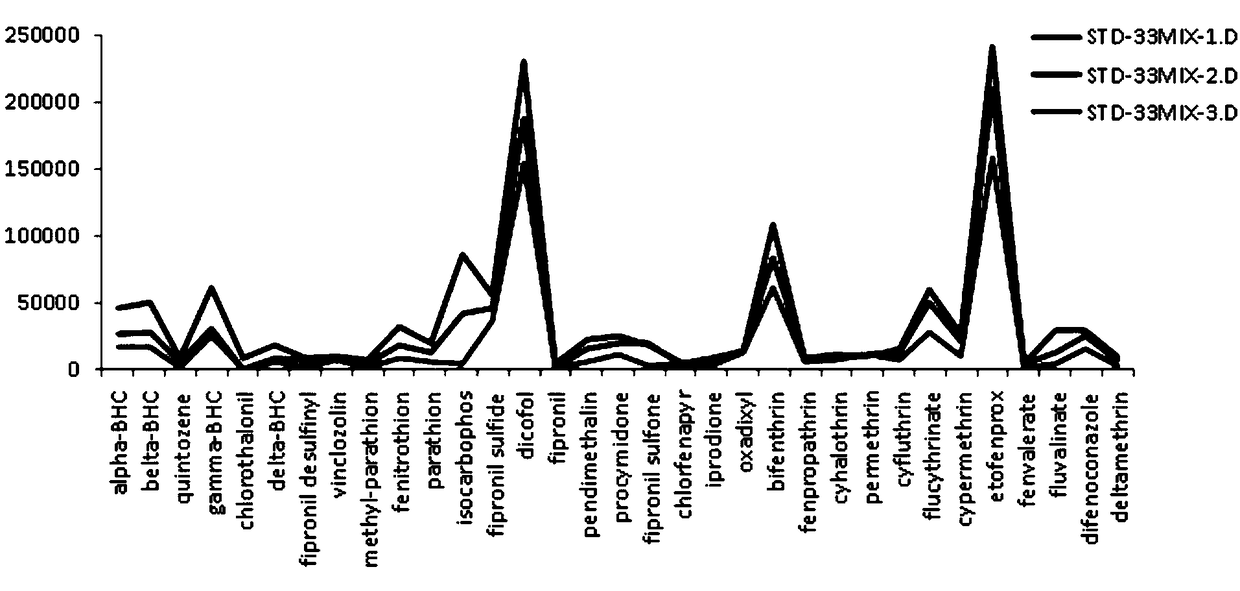

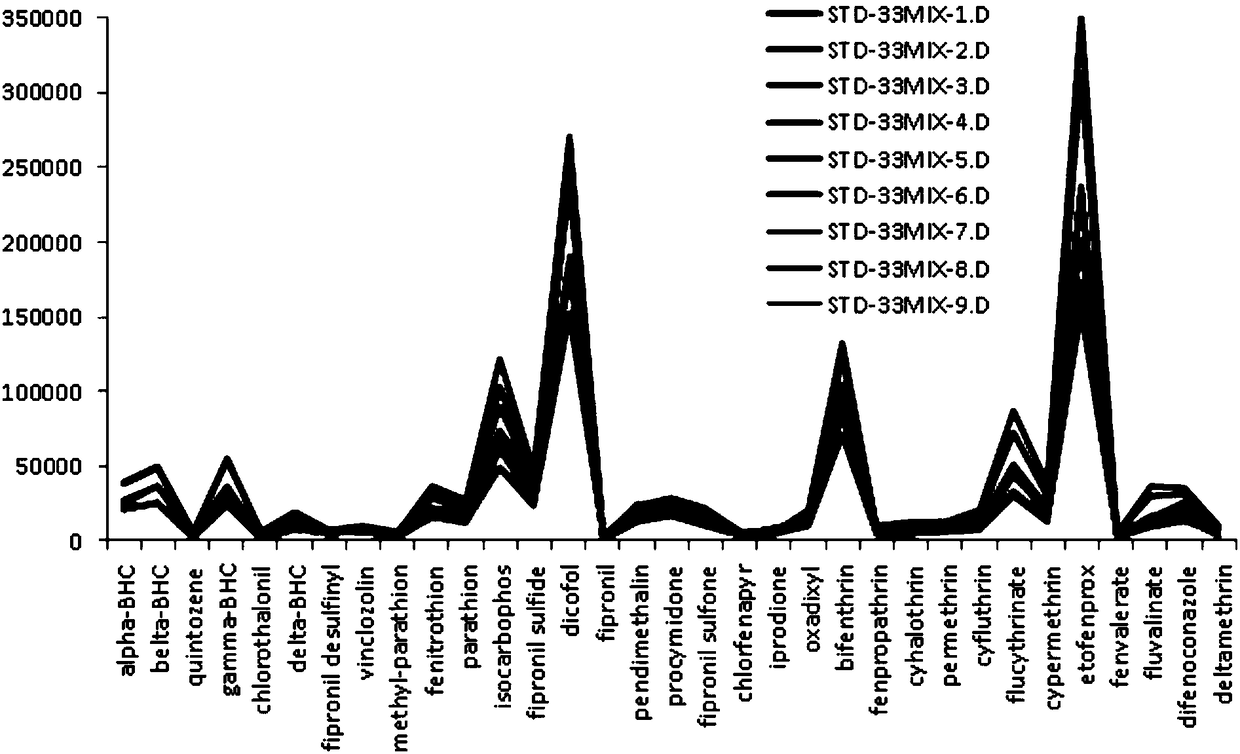

[0017] The present invention will be further described below in conjunction with the accompanying drawings.

[0018] A pretreatment and purification method for detection of pesticide residues by gas chromatography, comprising the following steps: 1) Weighing a uniformly pulverized sample and placing it in a centrifuge tube, adding acetonitrile into the centrifuge tube, and placing the centrifuge tube in a high-speed disperser High-speed homogenization;

[0019] 2) Continue to add sodium chloride and anhydrous magnesium sulfate to the centrifuge tube, continue homogenizing at a medium speed or violently shake, centrifuge the centrifuge tube, separate the acetonitrile and water phases in the centrifuge tube, and obtain the extract;

[0020] 3) Take the extract and add it to a centrifuge tube, and add toluene to make up the volume, then add a purification bag, shake vigorously, and centrifuge to obtain the supernatant;

[0021] 4) Take the supernatant obtained by centrifugation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com