Coking plant VOCs treatment system

A treatment system and control system technology, applied in the field of volatile organic compound VOCs treatment, can solve the problems of small adsorption, low membrane production rate, low operating cost, etc., to reduce environmental pollution and completely clean the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1: The present invention includes a control system, a combustion processing system and a negative pressure recovery system, and the control system is a programmable logic controller or a distributed control system.

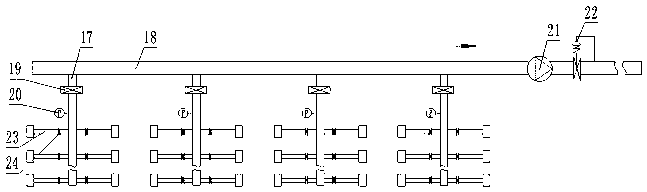

[0033] Such as figure 1 As shown, the negative pressure recovery system includes a plurality of exhaust gas discharge groups, and each exhaust gas discharge group includes a plurality of exhaust gas discharge points, and the pressure in each exhaust gas discharge point is maintained so that the breathing valve of each discharge point is always closed. Within the open range; each exhaust gas discharge group is communicated with the negative pressure gas pipeline 18 through a main pipeline 17, and each main pipeline 17 is connected with an automatic regulating valve II19 and a pressure transmitter II20, and the pressure transmitter II20 It is connected to the input circuit of the control system, the automatic regulating valve II19 is connected to t...

Embodiment 2

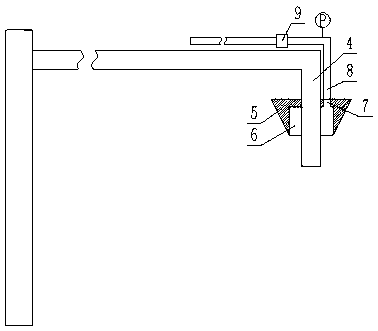

[0048] Embodiment 2: The difference between embodiment 2 and embodiment 1 is that, as Image 6 As shown, the waste gas conveying module includes a fan connected to the main pipeline, a check valve I and a quick shut-off valve I arranged behind the fan along the conveying direction of the main pipeline, and the quick shut-off valve I is connected to the output end circuit of the control system , The quick cut-off valve I can control the cut-off, connection or switching of the fluid in the main pipeline by accepting the instructions issued by the control system. Check valve Ⅰ is an automatic valve whose main function is to prevent the medium from flowing backward. When the system is abnormal or the combustible components exceed the standard, in order to empty the waste gas in the main pipeline, the main pipeline between the fan and the check valve I is connected to the chimney through a pipeline, and the pipeline is connected to the quick shut-off valve II. Valve II is connecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com