High-temperature critical treatment method and system for dioxin in waste incineration flue gas

A technology of waste incineration and treatment system, applied in the field of flue gas treatment, to achieve the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

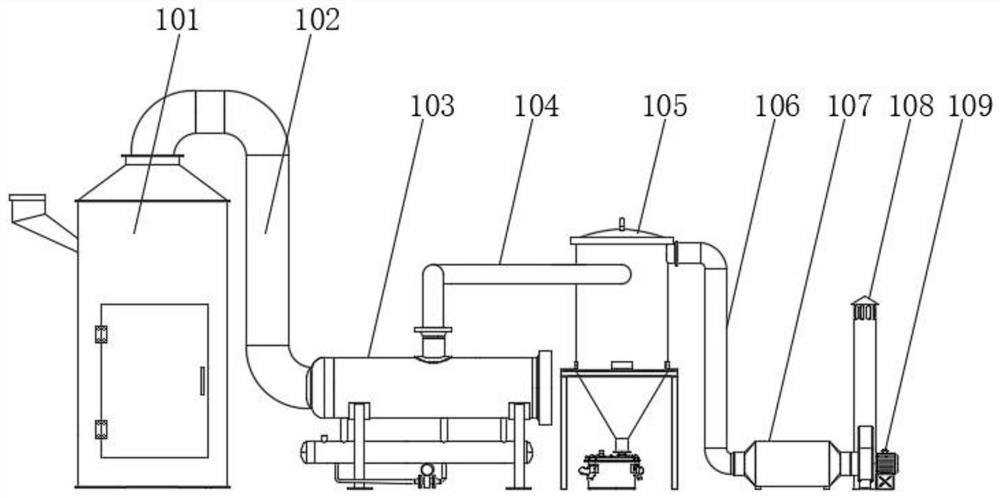

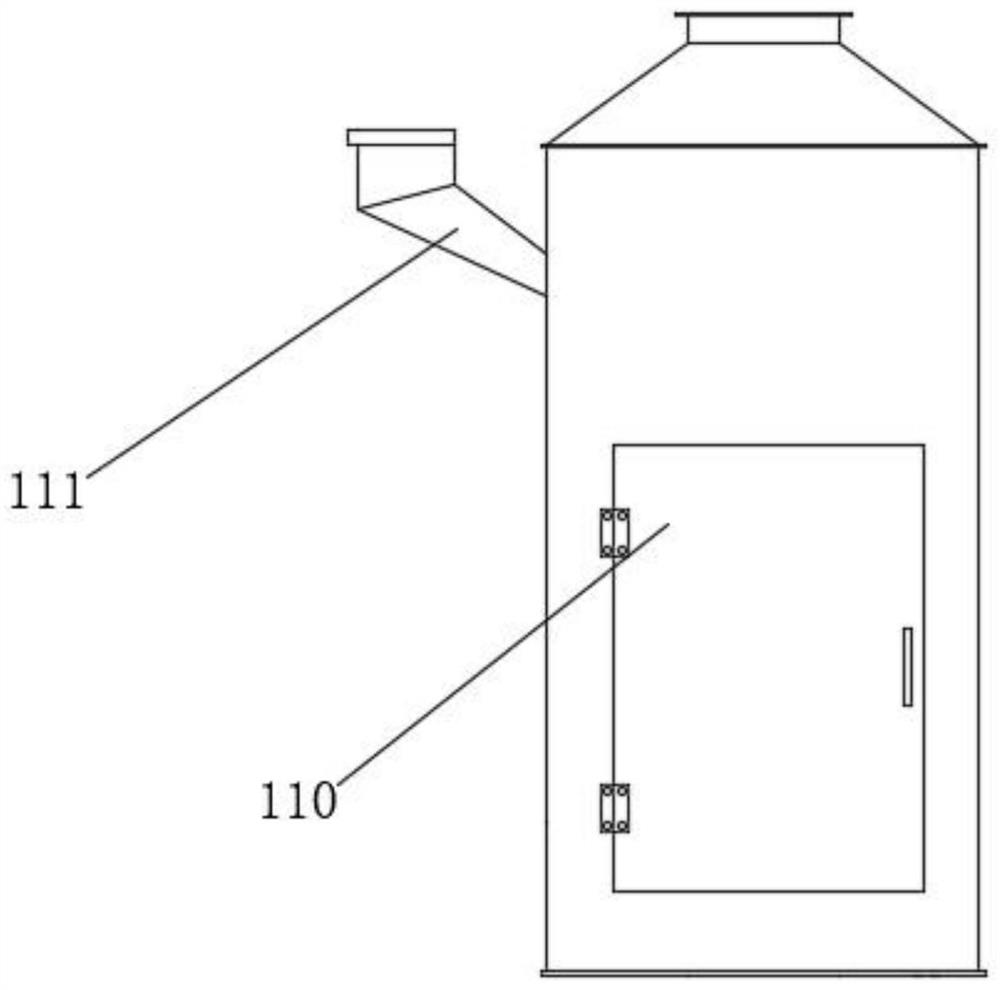

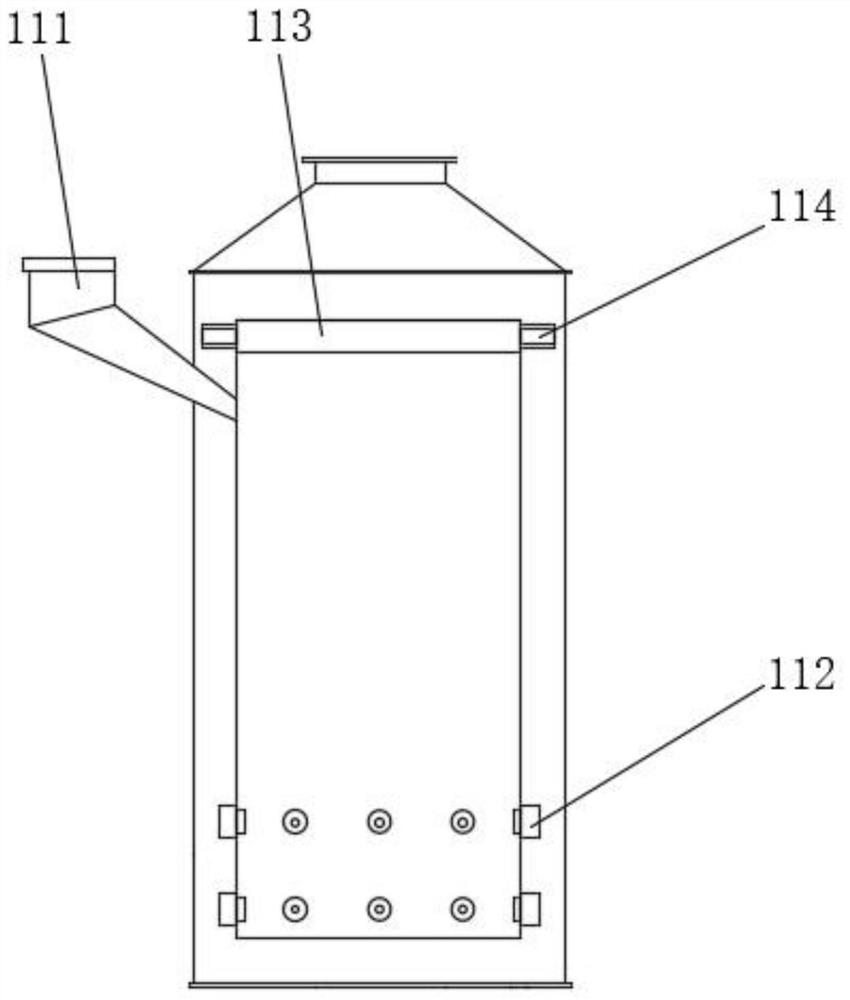

[0041] see Figure 1-10 As shown, a high-temperature critical treatment system for dioxins in waste incineration flue gas in this embodiment includes an incineration tower 101, a first smoke pipe 102, a spray mechanism 103, a second smoke pipe 104, and a cyclone separator 105 , the third smoke pipe 106, the adsorption box 107, the smoke exhaust pipe 108, the blower 109, the top of the burning tower 101 is equipped with the first smoke pipe 102, and the end of the first smoke pipe 102 away from the burning tower 101 is connected to the nozzle One end of the spraying mechanism 103, the top of the spraying mechanism 103 is equipped with a second smoke pipe 104, and the end of the second smoke pipe 104 away from the spraying mechanism 103 is installed on the top of one side of the cyclone separator 105 in a tangential direction, The other side top of the cyclone separator 105 is equipped with a third smoke pipe 106, and one end of the third smoke pipe 106 away from the cyclone sep...

Embodiment 2

[0049] see Figure 1-10 As shown, this embodiment is a high-temperature critical treatment method for dioxins in waste incineration flue gas, comprising the following steps:

[0050] Step 1: Open the airtight door 110 on the incineration tower 101 of the high-temperature critical treatment system for dioxins in waste incineration flue gas, mix the garbage and amino acid calcium in a weight ratio of 300-500:1, and then add them to the incineration tower 101 In the inner cavity of the inner cavity, close the airtight door 110, inject the reaction solution in the inner cavity of the liquid storage bin 119 by the liquid addition pipe 126; the reaction solution is a mixed aqueous solution of sodium thiosulfate and urea, wherein the massfraction of sodium thiosulfate is 10%, the mass fraction of urea is 5%;

[0051] Step 2: Start the flamethrower 112, several flamethrowers 112 release flames to incinerate the garbage and amino acid calcium, the smoke generated by the garbage passes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com