Foaming silica gel material and anti-slip heat isolation silica gel glove

A technology of foamed silica gel and gloves, which is applied in the direction of gloves, textiles, papermaking, coatings, etc., can solve the problems of destroying foaming performance, loss of use performance, loss of mechanical properties of gloves, etc., and achieves good mechanical stress dispersion performance and good mechanical properties. The effect of the strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

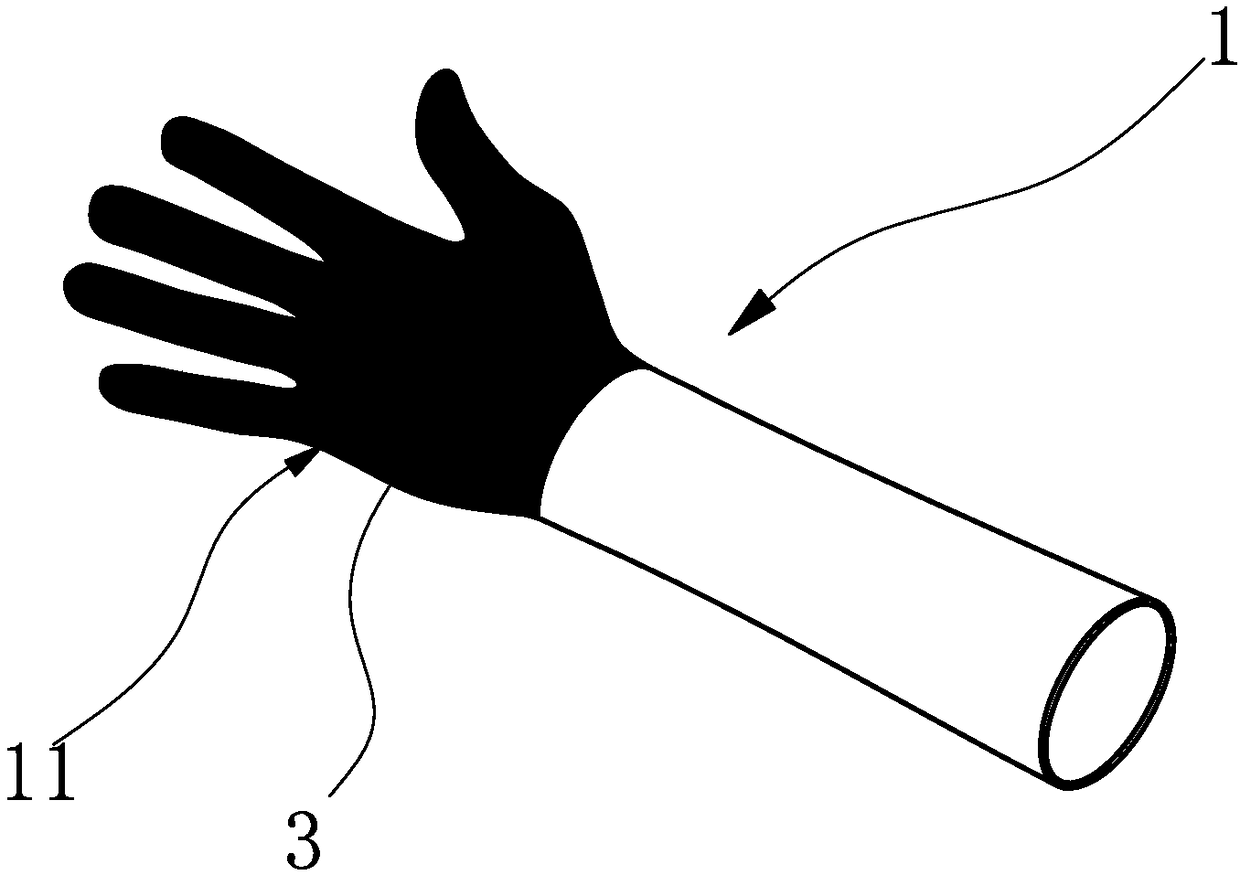

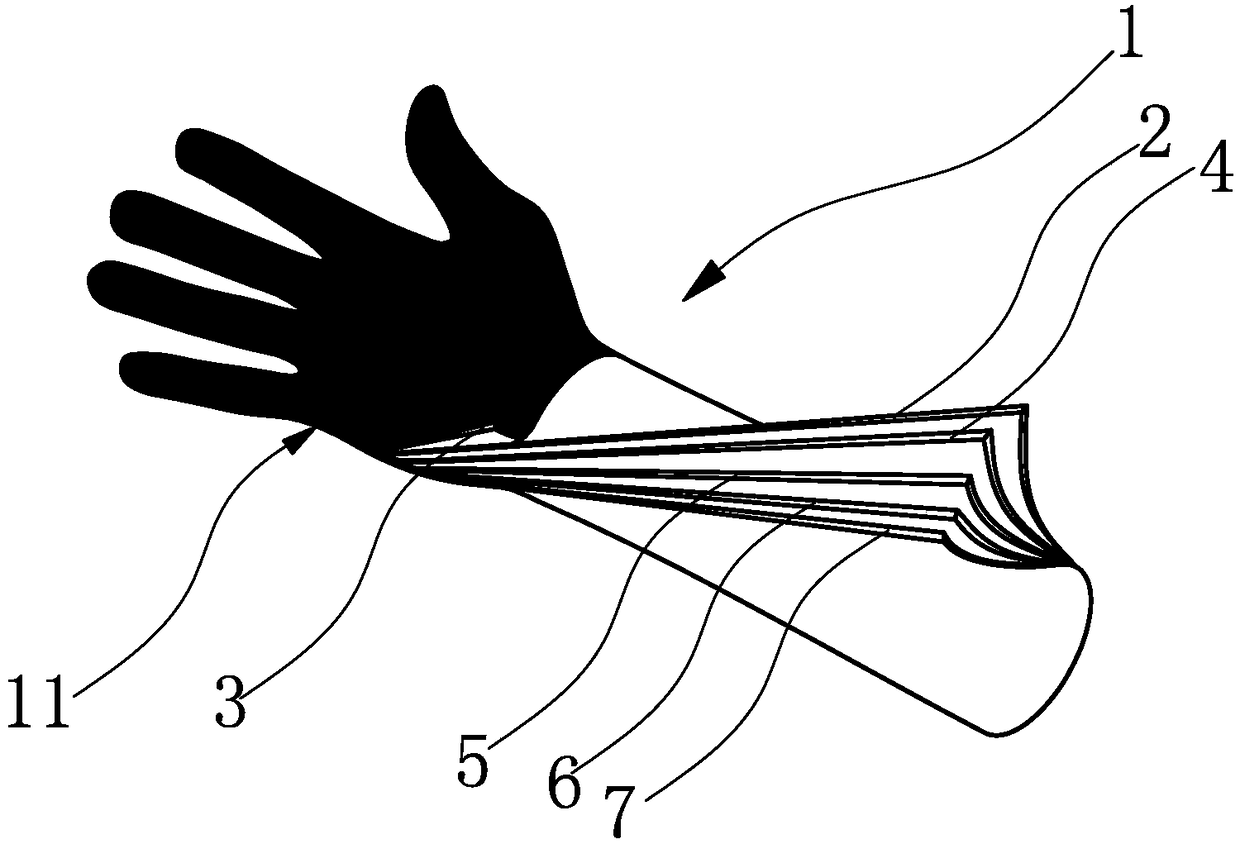

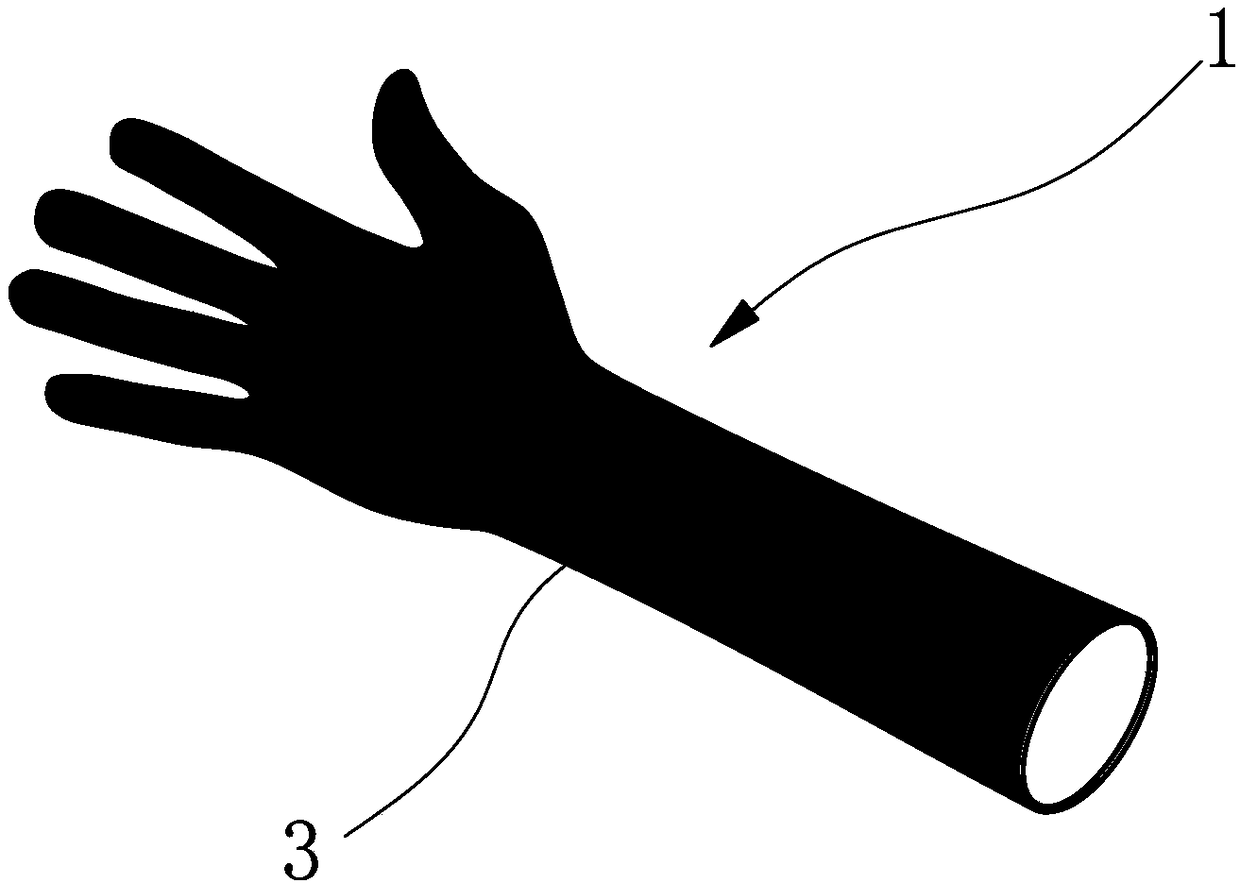

[0030] The non-slip and heat-insulating silicone glove of this embodiment includes a glove body 1, the glove body 1 has a silicone layer 2, and the outer surface of the silicone layer 2 of the grip portion 11 of the glove body 1 has a foam formed by foaming the following foamed silicone material Silicone coating 3: the glove body 1 also includes a smooth sweat-absorbing layer 7, a heat-insulating and cold-proof layer 6, a fabric lining 5, and an isolation layer 4 from the inside to the outside. The surface of the isolation layer 4 is a silicone layer 2; wherein, The foamed silica gel material contains heat-expandable microcapsules and addition-type silicone rubber, and based on the total mass of the foamed silica gel material, the mass content of the heat-expandable microcapsules is 1.0‰, the heat-expandable microcapsules have a core-shell structure, and the shell of the heat-expandable microcapsules is Polyethylene, the core layer is thermally expandable material pentane. Tes...

Embodiment 2

[0034] The non-slip and heat-insulating silicone glove of this embodiment includes a glove body 1, the glove body 1 has a silicone layer 2, and the outer surface of the silicone layer 2 of the grip portion 11 of the glove body 1 has a foam formed by foaming the following foamed silicone material Silicone coating 3: the glove body 1 also includes a smooth sweat-absorbing layer 7, a heat-insulating and cold-proof layer 6, a fabric lining 5, and an isolation layer 4 from the inside to the outside. The surface of the isolation layer 4 is a silicone layer 2; wherein, The foamed silica gel material contains heat-expandable microcapsules and addition-type silicone rubber, and based on the total mass of the foamed silica gel material, the mass content of heat-expandable microcapsules is 3.0‰, the rest is addition-type silicone rubber components, and the heat-expandable microcapsules are core-shell Structure, the shell layer of heat-expandable microcapsules is polypropylene, and the cor...

Embodiment 3

[0037] The non-slip and heat-insulating silicone glove of this embodiment includes a glove body 1, the glove body 1 has a silicone layer 2, and the outer surface of the silicone layer 2 of the grip portion 11 of the glove body 1 has a foam formed by foaming the following foamed silicone materials: Foam silicone coating 3: the glove body 1 also includes a smooth sweat-absorbing layer 7, a heat-insulating and cold-proof layer 6, a fabric lining 5, and an isolation layer 4 from the inside to the outside. The surface of the isolation layer 4 is a silicone layer 2; , the foamed silica gel material contains heat-expandable microcapsules and addition-type silicone rubber, and based on the total mass of the foamed silica gel material, the mass content of heat-expandable microcapsules is 15‰, and the rest are addition-type silicone rubber components. Here, heat-expandable microcapsules It is a core-shell structure, the shell layer of thermally expandable microcapsules is a composite of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com