Preparation method of high-temperature-resistant anchoring glue

A high-temperature-resistant, anchoring adhesive technology, used in adhesives, epoxy resin adhesives, adhesive types, etc., can solve the problems of poor high-temperature resistance, unable to meet the requirements of the construction industry, insufficient mechanical strength, etc., to improve mechanical properties. , Improve surface polarity and dispersion, improve high temperature resistance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

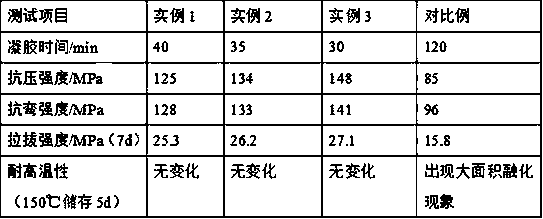

Examples

example 1

[0024]Mix and stir bisphenol A epoxy resin, bismaleimide resin and cyanate resin at a mass ratio of 2:1:1 for 20 minutes, heat up to 240°C to obtain a mixed resin, mix the mixed resin and the mass fraction Mix and stir 20% silica sol for 1 hour at a mass ratio of 1:2 to obtain a modified epoxy resin; weigh 32 g of diatomaceous earth, grind and pulverize it for 7 minutes, pass through a 100-mesh sieve, collect the sieved powder, and mix the sieved powder with silane The coupling agent KH-550 was mixed and stirred for 12 minutes according to the mass ratio of 1:2. After stirring, the mixture was obtained. Continue to add glucose with 6% of the mass of the mixture and yogurt with 0.9% of the mass of the mixture to the mixture, and put it into a fermenter. Sealed fermentation at 30°C for 9 days, after the end of the fermentation, take out the fermentation product, which is the modified diatomite powder; mix absolute ethanol and acetone for 10 minutes in an equal volume ratio to obt...

example 2

[0026] Mix and stir bisphenol A epoxy resin, bismaleimide resin and cyanate resin at a mass ratio of 2:1:1 for 25 minutes, heat up to 270°C to obtain a mixed resin, mix the mixed resin and the mass fraction 20% silica sol was mixed and stirred for 1.5 hours at a mass ratio of 1:2 to obtain a modified epoxy resin; 36g of diatomaceous earth was weighed, ground and pulverized for 8 minutes, and passed through a 100-mesh sieve to collect the sieved powder, and the sieved powder and The silane coupling agent KH-550 was mixed and stirred for 14 minutes according to the mass ratio of 1:2. After stirring, the mixture was obtained. Continue to add glucose with a mass of 6% of the mass of the mixture and yogurt with a mass of 0.9% of the mass of the mixture to the mixture, and put it into a fermenter. It is sealed and fermented at 35°C for 10 days. After the fermentation, the fermentation product is taken out, which is the modified diatomite powder; absolute ethanol and acetone are mixed...

example 3

[0028] Mix and stir bisphenol A epoxy resin, bismaleimide resin and cyanate resin at a mass ratio of 2:1:1 for 30 minutes, heat up to 300°C to obtain a mixed resin, mix the mixed resin and the mass fraction Mix and stir 20% silica sol for 2 hours at a mass ratio of 1:2 to obtain a modified epoxy resin; weigh 40 g of diatomaceous earth, grind and pulverize it for 9 minutes, pass through a 100-mesh sieve, collect the sieved powder, and mix the sieved powder with silane The coupling agent KH-550 was mixed and stirred for 16 minutes according to the mass ratio of 1:2. After stirring, the mixture was obtained. Continue to add glucose with a mass of 6% of the mass of the mixture and yogurt with a mass of 0.9% of the mass of the mixture to the mixture, and put it into a fermenter. Sealed fermentation at 40°C for 11 days, after the end of fermentation, take out the fermentation product, which is the modified diatomite powder; mix absolute ethanol and acetone for 12 minutes according to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com